Main Application:

Drying towers are widely used for spray drying of solutions, suspensions and other liquids containing dry matter into powdered products in food, additives, biology, medicine, chemical and other fields.

Main feature:

(1)The platform adopts the whole frame and detachable structure, which has good overall rigidity and small vibration.

(2)The equipment has a compact structure, small footprint and reliable operation; the optimized design of each component is particularly convenient for cleaning and replacement.

(3)Made of stainless steel, in line with food hygiene standards.

(4)Can be installed on the production line, automatic production, low labor intensity.

(5)The upper air inlet, the upper air exhaust, the wide tower body, The fog droplets can be re-aggregated once, and the fine powder can be re-aggregated twice, with a conjoined fixed fluidized bed, and dry spray drying system device with high and low temperature auxiliary drying function.

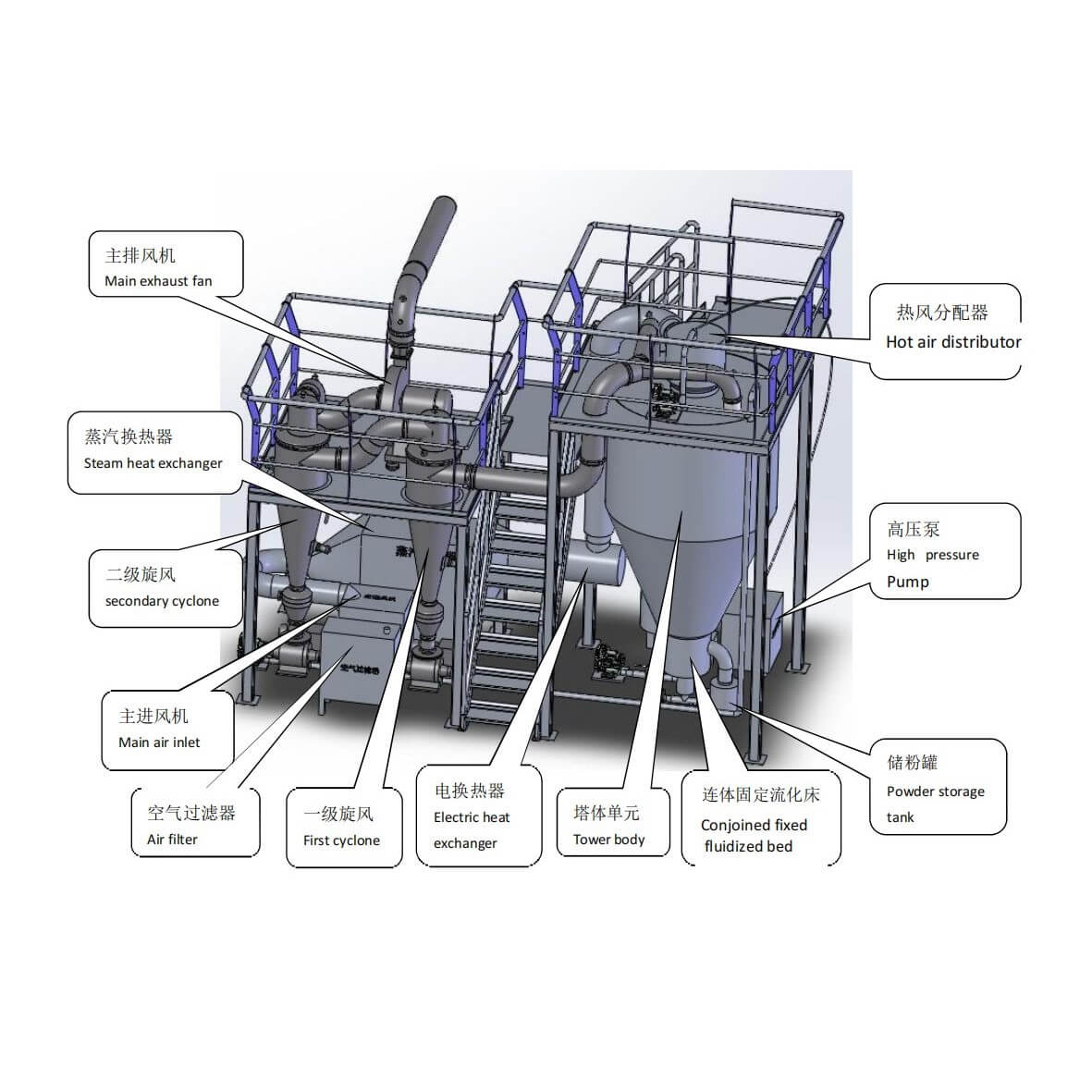

Overall structure:

As shown in the figure above, the equipment is mainly composed of platform, steam heat exchanger, electric heat exchanger, primary and secondary cyclones, tower body unit, powder storage tank, high pressure pump, main intake fan, main exhaust fan,Conjoined fixed fluidized bed,Hot air distributor,etc.

This machine adopts a new type of airflow structure of upper air intake and upper exhaust air, and the conjoined fixed fluidized bed is assisted in drying and cooling at low temperature. After the material is dehydrated, it is exposed to the low-temperature wind at the bottom, which makes product has good freshness and greatly reduces the denatured protein of the product. The spiral wind sweeps the tower wall, so that less powder is

accumulated inside wall of the tower. The tower body exhausts air symmetrically at two points, and the hot air distributor has a new air distribution structure, which does not need to be adjusted to ensure uniform air intake. There is a cold air ring on the top of the tower to avoid the problem of coke powder on the top of the tower. The cone courses of the tower are equipped with plunger reciprocating vibrator, which automatically circulates to vibrate the wall of the tower to avoid powder sticking and accumulating inside wall of the tower. The cyclone cone courses are equipped with pneumatic air hammer, which automatically and circularly knocks the cyclone cone courses, making sticky powder on the inner wall of the tower fall. The cleaning system adopts branch cleaning. The cleaning system adopts an instant cleaning device for shunt cleaning. During production, the cleaning device is evacuated from the inside of the equipment to avoid contact between the cleaning device and the material to reduce pollution sources. The operation adopts automatic control, equipped with frequency converter, temperature sensor, PLC program control and a set of manual control system, which is simple to operate and easyto control.

Working Principle:

The concentrated material enters the tower body through the vertical high-pressure pump, At the same time, the air heated by steam heat exchanger or electric heat exchanger also enters the tower body. After the concentrated material enters the tower body, it issprayed through the nozzle at high pressure to form mist droplets. The droplets meet with the hot air, and the water in the droplets is evaporated by the hot air, thereby dehydrating the concentrated material to form fine powder. The fine powder falls into the conjoined static fluidized bed under the tower body by wind force and its own gravity, and then the finished powder on the static fluidized bed is blown into the powder storage tank by the blower, and finally becomes the finished product. The waste wind finishing heat exchange by entering in the tower body will be discharged through the first-level cyclone and the secondlevel cyclone in turn. A small part of the fine powder carried away by the waste wind is recycled twice by the first cyclone and the second cyclone. The recovered fine powder falls into the wind-driven rotary valve below and enters the tower body again through the fine powder recombination pipeline for secondary polymerization and granulation. In this way, the material can 100% complete atomization and dehydration transformation as well as

polymerization and granulation. Product particles are of uniform, fresh color, good disperal,low loss rate. Finally, the finished product is transported to the next process.

If you got any question about Experimental Drying Tower, please contact Beyond service engineer freely.