Influence of pre-heating

Feeding temperature. The temperature of the feed liquid before entering the evaporator is generally low, and the evaporation of the low-temperature feed is different from the completion of the feed at a temperature equal to or higher than the boiling point, regardless of the type of evaporator. The feed temperature is an important parameter in the design of the evaporator, in the production process, the temperature of the feed liquid entering the evaporator can be increased as much as possible to achieve high-temperature feed instead of low-temperature feed. If the material does not reach the boiling point temperature, there is a preheating section in the heat transfer area of the evaporator. Even so, the effect is not good and it is easy to cause scaling and coking faster, and it is difficult to achieve continuous discharge. This has been confirmed long time ago in the application of falling film evaporator. The low-temperature feed to the falling film evaporator is preheated step by step to the boiling point or above the boiling point before entering the evaporator for evaporation.

Heat transfer temperature difference should not be too large:

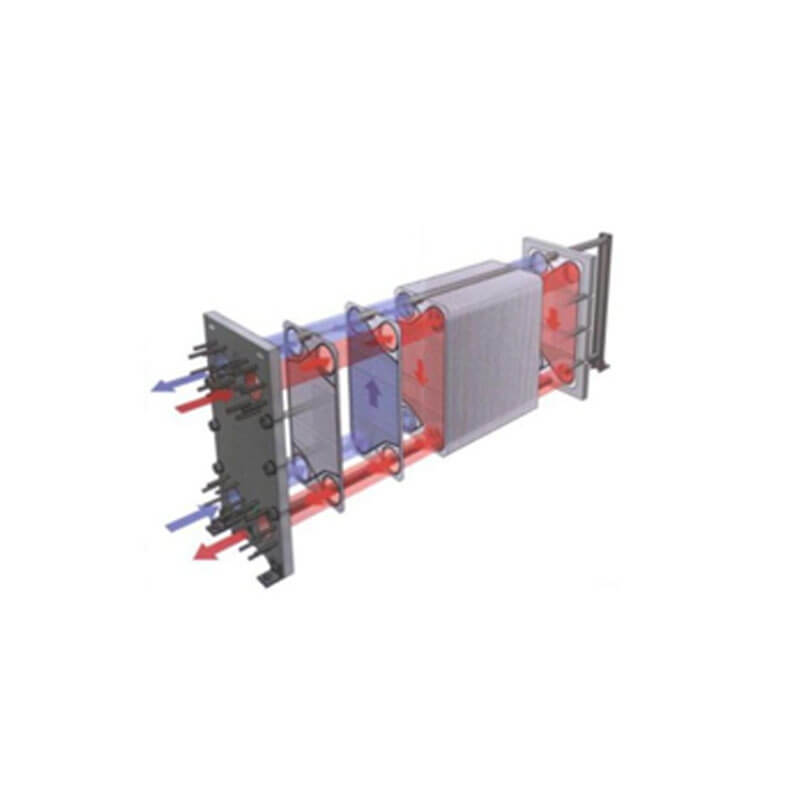

For continuous feeding and continuous discharging, the heat transfer temperature difference cannot be selected too large. The reason why the falling film evaporator can continuously feed and discharge materials is that its heat transfer temperature difference is relatively small, generally between 8-15°C, and the highest does not exceed 18°C. The falling film evaporator evaporates under negative pressure and low temperature, and its heating temperature mostly does not exceed 100°C. Its heat transfer temperature difference is the smallest among all evaporators, and its heat transfer area is also the largest among all evaporators based on same evaporation capacity. The movement and evaporation state of the feed liquid in the falling film evaporator are also completely different from other evaporator

Reasonable sections :

For falling film evaporators or forced circulation evaporators, separated sections can be performed according to calculations, separated sections can increase the surrounding wetting volume or flow rate, effective and reasonable sections can make evaporation reach an optimal state and make evaporation proceed quickly

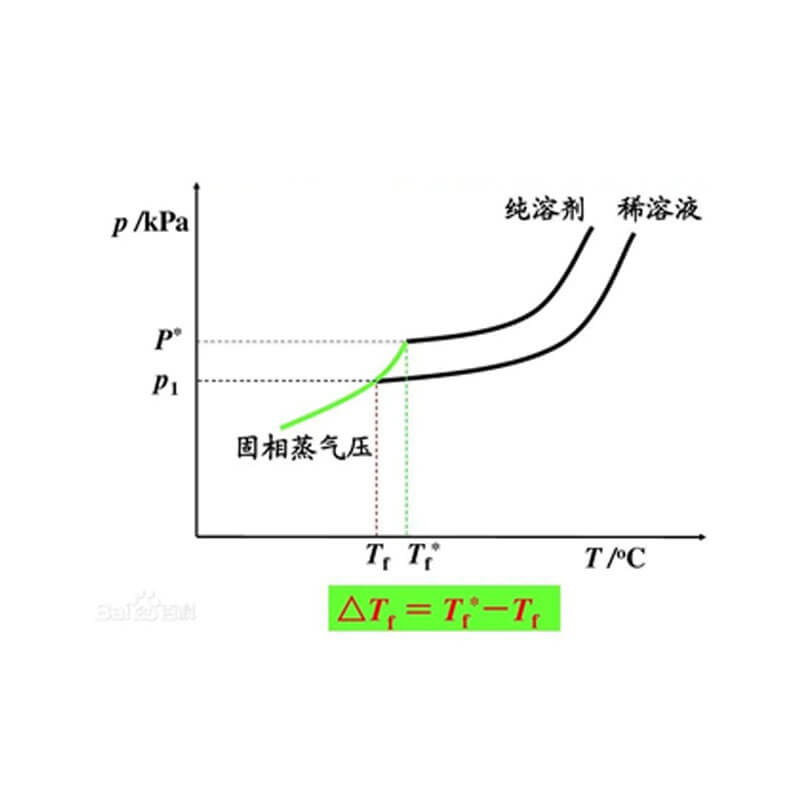

Elevated boiling point:

The boiling point of some materials increases greatly during the evaporation process, and the heat transfer area is also greatly affected by the increase in boiling point, 1°C increase in boiling point can even double the evaporation area.

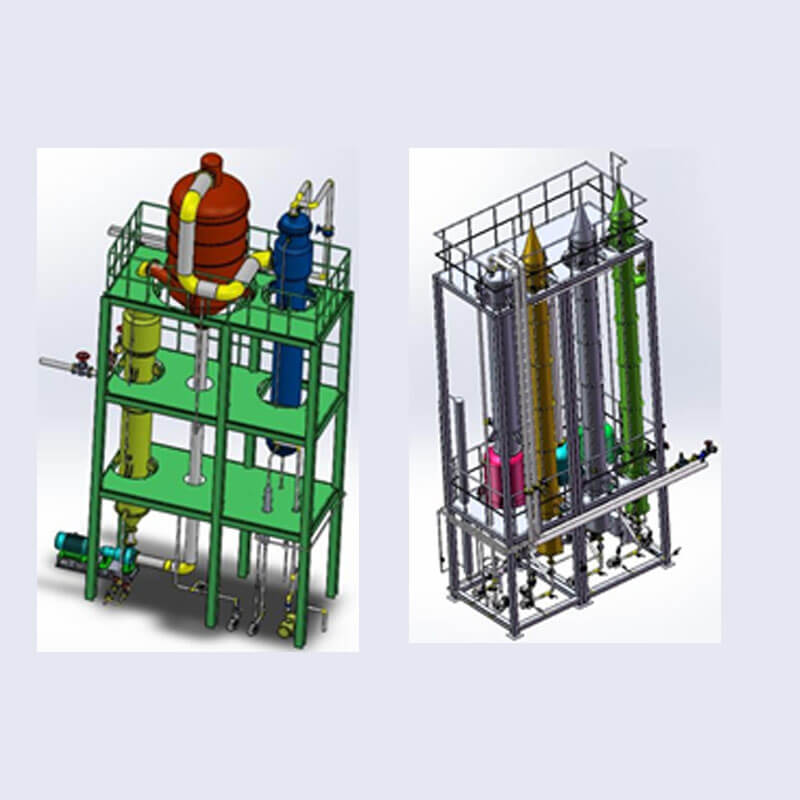

Selection of evaporator types:

When choosing an evaporator, you must know the characteristics of the material and its evaporation parameters, and choose the type of evaporator according to the characteristics of the material and evaporation parameters, especially the viscosity parameter. It is also necessary to use the method of doing experiments to analyze, and then confirm what kind of evaporator.

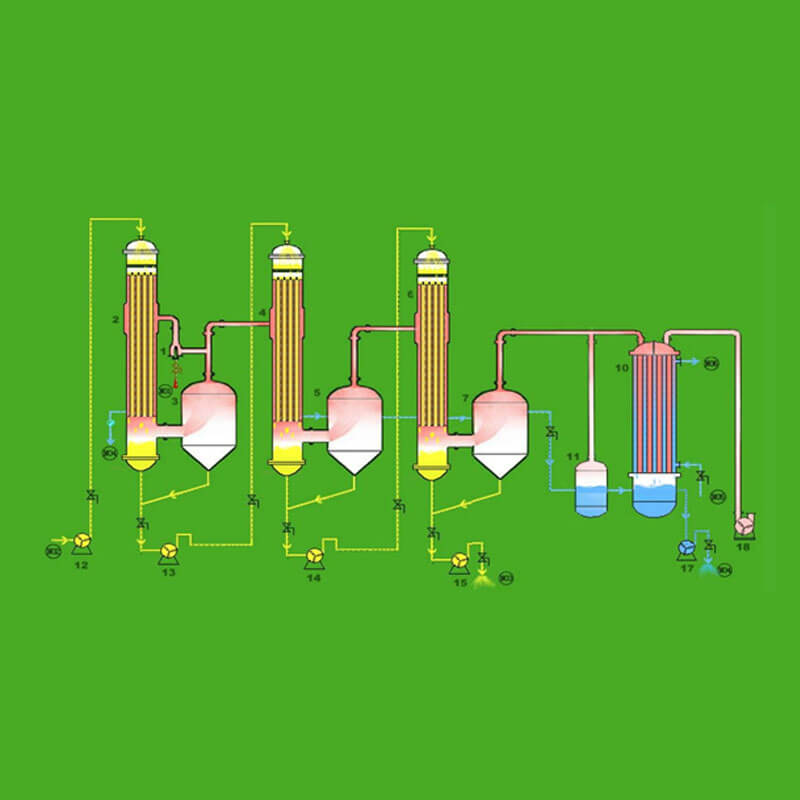

Concentration ratio range:

To realize the continuous feed and discharge of evaporator, the concentration ratio should not be large. No matter what kind of evaporator adopts single-effect evaporation and multi-effect evaporation, the effect is completely different. Multi-effect evaporation is easy to improve solid content, while single-effect evaporation is difficult. Single-effect falling film evaporator can continuously feed and discharge in the production of liquid milk, because its concentration ratio is small, liquid milk after concentration to improve the dry matter content is limited, its concentration ratio is about 1.173. However, if the discharge concentration of single-effect falling film evaporator is higher, it exceeds the concentration ratio range of continuous feed and continuous discharge, and it still cannot be continuous feed and continuous discharge. The concentration ratio of single-effect external circulation evaporator is generally about 7.5, so it is difficult to produce continuously. Falling film evaporator, especially the most commonly used three-effect falling film evaporator, also has concentration requirements, and its concentration ratio ranges from 2.67-3.91. For example, the concentration of date juice is generally required to be from about 8%-10% to 75%, which has not reached the production capacity in practical application. That is to say, to achieve the concentration of the production process is not allowed to rely on reflux, intermittent discharge, in fact, still can not reach the designed evaporation capacity. Generally, it is safer to use the process of fractional evaporation, or to take the method of small temperature difference and large evaporation area for evaporation, but in fact, it violates the scope of the concentration ratio of the evaporator, which is mainly related to the user and the design enterprise.