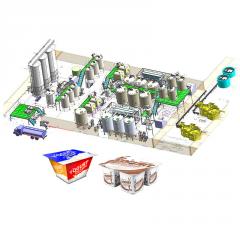

A condensed milk processing line is a series of machines and equipment used to produce condensed milk from raw milk. The process typically involves the following steps:

1. Raw material preparation: Select fresh and uncontaminated milk, conduct preliminary processing and inspection to ensure the quality of raw materials.

2. Standardization: Adjust the fat content and protein content of milk to meet production standards.

3. Preheating: Preheating milk to a certain temperature will help the subsequent concentration and sterilization process.

4. Concentration: Evaporate the water in the milk through an evaporator to increase the solid content and form concentrated milk.

5. Saccharification (optional): For sweet condensed milk, add an appropriate amount of sugar to the concentrated milk and stir evenly.

6. Homogenization: Use a homogenizer to break the fat globules in the condensed milk into smaller particles to prevent stratification and improve the taste.

7. Sterilization: Heat the condensed milk to a high temperature and sterilize it to ensure the safety of the product.

8. Cooling: Cool the sterilized condensed milk quickly to a suitable temperature to prevent bacterial growth.

9. Filling and sealing: Fill the condensed milk into canned or bottled containers and seal them to ensure the hygiene and shelf life of the product.

10. Quality control: Conduct sensory and laboratory tests on finished products to ensure product safety and quality.

11. Storage and transportation: Store products in a suitable environment, choose appropriate transportation methods and cold chain systems to ensure that products are not affected by temperature during transportation.

Overall, a condensed milk processing line follows strict hygiene and quality control measures to ensure the production of safe and high-quality.

ADVANTAGES:

1.Opportunity to realize products with customized recipes.

2.Opportunity to produce more than one product with the same processing line.

3.Wide customization of the final product.

4.Maximum yield, minimum production waste.

5.Highest energy savings thanks to the most advanced technologies.

6.Complete line supervision system through monitoring of every process phase.

7.Recording, visualization and printing of all daily production data.

Raw materials and products of condensed milk production line

1. Raw materials

The raw materials required for the production of condensed milk mainly include dairy products and other auxiliary raw materials. The following is a detailed list of raw materials:

• Fresh milk: the main raw material, select fresh and uncontaminated milk, and undergo preliminary processing and inspection to ensure the quality of the raw materials.

• Sugar: such as sucrose and glucose syrup, used to increase the sweetness of condensed milk and improve the taste.

• Stabilizer: such as carrageenan and xanthan gum, used to improve the stability and taste of condensed milk.

• Emulsifier: such as monoglyceride and lecithin, used to improve the structure of condensed milk and prevent stratification.

• Flavor: such as vanilla flavor and coconut flavor, used to increase the flavor of condensed milk.

• Pigment: such as natural pigment (beet red, carotene), used to adjust the color of condensed milk.

• Preservative: such as potassium sorbate, used to extend the shelf life of condensed milk.

• Vitamins and minerals: such as vitamin A, D, calcium, used to enhance the nutritional value of condensed milk.

2. Products

The condensed milk production line can produce many different types of condensed milk products. The following are some common product types:

•Sweetened condensed milk: Add the right amount of sugar, high sweetness, rich taste, suitable for direct consumption or for baking and cooking.

•Sugar-free condensed milk: Use sugar substitutes (such as stevia, erythritol) instead of sucrose, suitable for diabetics or people on a low-sugar diet.

•Low-sugar condensed milk: Reduce the addition of sugar, suitable for people who need to control sugar intake.

•Flavored condensed milk: Such as vanilla condensed milk, coconut condensed milk, chocolate condensed milk, by adding different flavors and seasonings, provide a variety of flavor options.

•Fortified condensed milk: Add vitamins and minerals, such as vitamin A, D, calcium, to enhance the nutritional value of condensed milk, suitable for nutritional supplements.

•Organic condensed milk: Use organic milk and organic ingredients, follow the standards of organic agriculture, and do not contain chemical pesticides and hormones.

•Concentrated condensed milk: Through the concentration process, reduce moisture and increase solid content, suitable for long-term storage.

|

Working Capacity

|

From 5 tons/d up to 100 tons/d

|

|

Products

|

- Sweetened condensed milk

|

|

- Evaporated milk without sugar

|

|

|

- Condensed milk in varied package

|

The Condensed Milk Processing Line is a specialized system designed for the production of various types of condensed milk, including sweetened condensed milk, light condensed milk, and prepared condensed milk. The customization of this processing line can be tailored to meet specific client requirements and production capacities.

Equipment specifications (e.g., type of evaporator or filling machine).