Main production steps of coconut water processing line Coconut water is a natural and healthy drink, and its processing needs to be strictly controlled to ensure the safety and quality of the product. The following are the main production steps of coconut water processing line:

I. Raw material preparation

1. Coconut selection

• Standard: Select green coconuts or old coconuts with moderate maturity, usually 6-7 months old coconuts, with high moisture content and rich nutrition.

• Inspection: Remove coconuts with cracks, mildew or other defects to ensure the quality of raw materials.

2. Cleaning

• Method: Use a high-pressure water gun to thoroughly clean the surface of the coconut to remove dirt, impurities and possible pesticide residues.

• Equipment: Equipped with a bubbling cleaning machine and a spraying device to ensure the cleaning effect.

II. Shelling and water extraction

3. Shelling

• Tools: Use a professional coconut shelling machine to remove the coconut shell by mechanical force.

• Features: High efficiency, reduce manual operation, and avoid pollution.

4. Water extraction

• Method: Use aseptic drilling water extraction technology to drill holes from the top of the coconut and extract coconut water.

• Equipment: Equipped with a sterile water intake system to ensure that the coconut water is not contaminated during the extraction process.

III. Pretreatment

5. Filtration

• Purpose: Remove impurities and large particles in coconut water.

• Equipment: Use multi-stage filters, such as sand filters, activated carbon filters, etc., to ensure that the coconut water is clear and transparent.

6. Centrifugal separation

• Purpose: Further remove tiny suspended matter and improve the purity of coconut water.

• Equipment: Use a high-speed centrifuge to make coconut water clearer.

IV. Blending and homogenization

7. Blending

• Purpose: Add appropriate amounts of sugar, vitamin C, flavors and other ingredients according to the product formula to improve taste and stability.

• Equipment: Use a mixing tank for uniform stirring to ensure that all ingredients are fully integrated.

8. Homogenization

• Purpose: Make the particles in coconut water more delicate, uniform in texture, and smooth in taste.

• Equipment: Use a high-pressure homogenizer to ensure stable product quality.

V. Sterilization and Packaging

9. Sterilization

•Method: Use high temperature instantaneous sterilization (HTST) or ultra-high temperature instantaneous sterilization (UHT) technology to ensure product safety and hygiene.

•Equipment: Equipped with advanced sterilization equipment to ensure sterilization effect.

10. Filling

•Method: Quantitatively fill the sterilized coconut water into sterile containers.

•Equipment: Use an automated filling machine with high precision and high speed, which is suitable for various packaging forms (such as bottles, cans, and bags).

11. Sealing

•Method: Seal the filled containers to ensure the safety of the products during storage and transportation.

•Equipment: Equipped with an automatic sealing machine, which has a firm seal and good leak-proof performance.

VI. Quality Control and Testing

12. Online Testing

•Purpose: Real-time monitoring of various parameters in the production process (such as temperature, humidity, pH value, microbial indicators, etc.).

•Equipment: Equipped with online detectors to ensure accurate data and rapid response.

13. Laboratory Testing

•Purpose: Comprehensive quality inspection of finished products, including physical and chemical index analysis, microbial testing, etc.

•Equipment: Use advanced laboratory testing equipment to ensure product safety and compliance.

Main production steps of coconut milk processing line As a popular plant-based beverage, the processing of coconut milk needs to be strictly controlled to ensure the safety and quality of the product. The following are the main production steps of coconut milk processing line:

I. Raw material preparation

1. Coconut selection

• Standard: Select old coconuts with moderate maturity, usually 9-12 months old, with thick coconut meat and rich in oil.

• Inspection: Remove coconuts with cracks, mildew or other defects to ensure the quality of raw materials.

2. Cleaning

• Method: Use a high-pressure water gun to thoroughly clean the surface of the coconut to remove dirt, impurities and possible pesticide residues.

• Equipment: Equipped with a bubbling cleaning machine and a spraying device to ensure the cleaning effect.

II. Shelling and meat removal

3. Shelling

• Tools: Use a professional coconut shelling machine to remove the coconut shell by mechanical force.

• Features: High efficiency, reduce manual operation, and avoid pollution.

4. Crushing and extracting the meat

•Method: Put the shelled coconut into a crusher, crush it into small pieces, and then use a meat scraper to separate the coconut meat from the coconut shell.

•Equipment: Use stainless steel crushers and meat scrapers to prevent pollution and improve efficiency.

III. Refining and pressing

5. Refining

•Purpose: Grind the coconut meat into fine coconut milk.

•Equipment: Use efficient refiners, such as colloid mills or screw extrusion refiners, to ensure that the coconut milk is fine and particle-free.

6. Pressing

•Purpose: Extract coconut milk from coconut milk and remove residues.

•Equipment: Use a multi-stage press or centrifugal separator to make the coconut milk purer and free of solid residues.

IV. Blending and homogenization

7. Blending

•Purpose: Add appropriate amounts of water, sugar, stabilizers and other ingredients according to the product formula to improve taste and stability.

•Equipment: Use a mixing tank for uniform mixing to ensure that all ingredients are fully integrated.

8. Homogenization

•Purpose: To make the fat particles in coconut milk more delicate, uniform in texture, and prevent stratification.

•Equipment: Use high-pressure homogenizer to ensure stable product quality.

V. Sterilization and Packaging

9. Sterilization

•Method: Use high-temperature instantaneous sterilization (HTST) or ultra-high temperature instantaneous sterilization (UHT) technology to ensure product safety and hygiene.

•Equipment: Equipped with advanced sterilization equipment to ensure sterilization effect.

10. Filling

•Method: Fill the sterilized coconut milk quantitatively into sterile containers.

•Equipment: Use automated filling machines with high precision and high speed, suitable for a variety of packaging forms (such as bottles, cans, and boxes).

11. Sealing

•Method: Seal the filled containers to ensure the safety of the products during storage and transportation.

•Equipment: Equipped with automatic sealing machines, with firm sealing and good leak-proof performance.

VI. Quality Control and Testing

12. Online Testing

•Purpose: Real-time monitoring of various parameters in the production process (such as temperature, humidity, pH value, microbiological indicators, etc.).

•Equipment: Equipped with online testing instruments to ensure accurate data and rapid response.

13. Laboratory Testing

•Purpose: Comprehensive quality inspection of finished products, including physical and chemical index analysis, microbiological testing, etc.

•Equipment: Use advanced laboratory testing equipment to ensure product safety and compliance.

Production Line Equipment Selection Recommendations When selecting coconut water processing production line equipment, the following factors should be considered comprehensively:

•Production capacity: Select appropriate equipment specifications according to the actual needs of the enterprise to ensure capacity matching.

•Degree of automation: Prioritize equipment with a high degree of automation to improve production efficiency and product quality.

•Energy saving and environmental protection: Pay attention to the energy efficiency ratio and environmental performance of the equipment, reduce operating costs, and meet the requirements of sustainable development.

•Maintenance convenience: Select equipment that is easy to clean and maintain, extend service life, and reduce downtime.

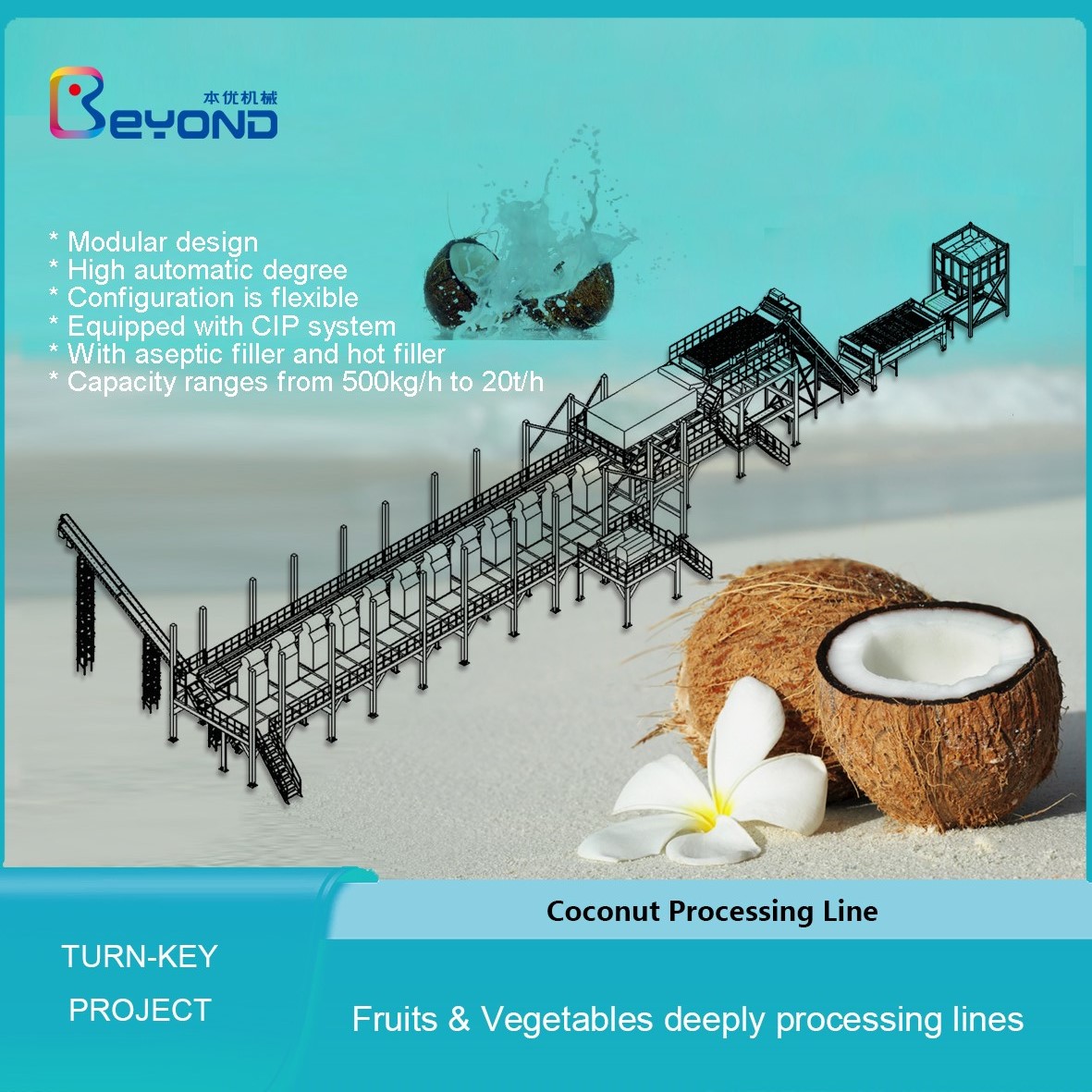

Suitable for all kinds of coconut to produce coconut water, coconut milk, juice with coconut ,coconut powder and etc. This processing line is combined with peeler, pulverizer, screw separator, filtration, disc centrifugal separator, blending system, degasser, homogenizer, sterilizer, filler, flusher, autoclave, ink coder and etc. With advanced design philosophy, high degree of automation; Main equipments are all made of high quality food grade stainless steel, accords with the hygienic requirements of food processing.

* Produce coconut water, coconut milk, coconut juice and etc

* Capacity ranges from 500kg/h to 20t/h,designed by the customer's needs

* Configuration is flexible, according the requirement of client to prepare the suitable machine

* With aseptic filler and hot filler

* Modular design, which can combine different processing technique

* High automatic degree, labor-saving

* Equipped with CIP to make clean easy

* Material contacted with production is SUS304 stainless steel, fully meets the food hygiene safety requirements

PARAMETER

| Raw Material | Coconut shell and coconut meat |

| End products | coconut water and milk, coconut cream, coconut oil |

| End Package | Aseptic bags in drums, bottles, tin cans, cartons |

| Processing products | UHT water and milk |

--Concentrate Coconut water filled into aseptic bags(5kg,220kg or 1000kg)

--Single strength coconut water(Non-concentrated coconut water)filled into tin cans,bottles or asptic bags.

--Coconut milk/cream filled into aseptic bags,tin cans or bottles.

--Desiccated Coconut filled into poly bags,jars or pouches.

--Virgin Coconut Oil(VCO)filled into bottles or barrels.

Single Strength Coconut water is a refreshing and cooling drink. Its sodium and potassium content makes it an ideal drink for rehydration. In a healthy, undamaged coconut, the water is even sterile. Fresh coconut after dehusking and deshelling, then use one needle to pierce one hole on the coconut to extract coconut water. After extraction, coconut water is filtered. Filtration can be done using a double cloth filter. This is especially important for mature coconut water, as dry husk fibres and dirt from the shell of mature nuts can easily get into the coconut water during extraction. After filtration, the coconut water is quickly cooled to retard any deterioration reactions. Then, it is sent for separation, homogenizing, degassing, subsequent pasteurization and aseptic packaging.

If coconut water is extracted at a location away from the aseptic packaging site, the filtered coconut water can be packed into food grade plastic bags, quickly cooled and transported to downstream processing. The single strength coconut water content is 92%-95% and soluble solids is about 12 brix.

Concentrated coconut water: Concentrated coconut water is about 60-65 brix and water content is about 35%-40%. Fresh coconut water after extracting, filtering, cooled to 10 ℃ and storing into double layers insulation tanks. Then the low-temperature coconut water will be prepasteurization and separation. Then, it goes into a multiple-effect evaporation stage to increase °Brix levels. Usually, the product is concentrated to 60-65 °Brix and packed into 200 kg plastic bags in drums for bulk transportation under ambient conditions. It is recommended that the concentrate coconut water will be stored at below zero temperature for 2 years.

Coconut milk/cream: Coconut milk and cream are produced from 10-13 months old mature coconuts when the kernel is hard and thick. They are natural oil-in-water emulsions extracted from the mature coconut kernel. The difference between coconut milk and cream is the amount of fat. The fat content of the coconut milk is 5%-20%, whereas coconut cream reaches to 20%-50%. To extract coconut milk for industrial manufacturing purposes, mature coconuts go through deshelling and paring. Pieces of kernels are then sent into industrial-scale cutters and grinders. Next, grated coconut kernel then goes into a series of screw extractors to extract coconut milk. The residual kernel from this first press is then mixed with water before it is pressed again to increase extraction yield. After extraction, coconut milk is filtered to remove large contaminants. It can then be standardized to a pre-determined level of fat and blended with other ingredients. Finally, coconut milk is homogenized, degassed, pasteurized and aseptically filled into aseptic bags or small package like bottles or tin cans.

Coconut oil: Coconut oil is one of the main products traditionally derived from the coconut kernel. Coconut oil processing methods or technologies are classified into two major types based on copra or fresh coconut kernel used. The oil extraction technology, which starts with copra as the raw material, is commonly known as the dry process. While the method that uses fresh coconuts as starting material is generally called the fresh-wet or fresh-dry process. Based on different separation methods, coconut oil can be classified into two types – RBD coconut oil and virgin coconut oil (VCO). The former is refined, bleached and deodorized (RBD) from dry extraction, while the latter is produced by fresh-wet and fresh-dry extractions.

Key Machine of Coconut Water and Milk Processing Line:

Coconut water extracting machine

It is composed of a coconut water drilling machine and a coconut water extraction conveyor,the machine is made of SUS304 material and with vat for coconut water collection.It is semi-automatic,one operator holds the coconut and aims the coconut eye to the drill to get the water then pours coconut water into the conut water collection vat.

Coconut dehucking machine

Coconut dehusking machine is to remove the outer hard huck.This type of peeling machine is semi-automatic equipment.It is mainly composed of a round cutter plate,a hard alloy cutter head,a wedge blade knife and a geared motor.When the machine is working,manually hold the coconut,align the position of the front coconut eye with the sprout blade,and press it down.At this time,the rotating peeling blade and the wedge-shaped top blade squeeze the coconut placed in it,thus smoothly peeling the coconut meat.The whole machine is designed for fixed installation and height-adjustable placement,which can satisfy both large-scale production line use and individual independent use,and has a wide range of adaptability.The capacity is 200-300PCS/H.

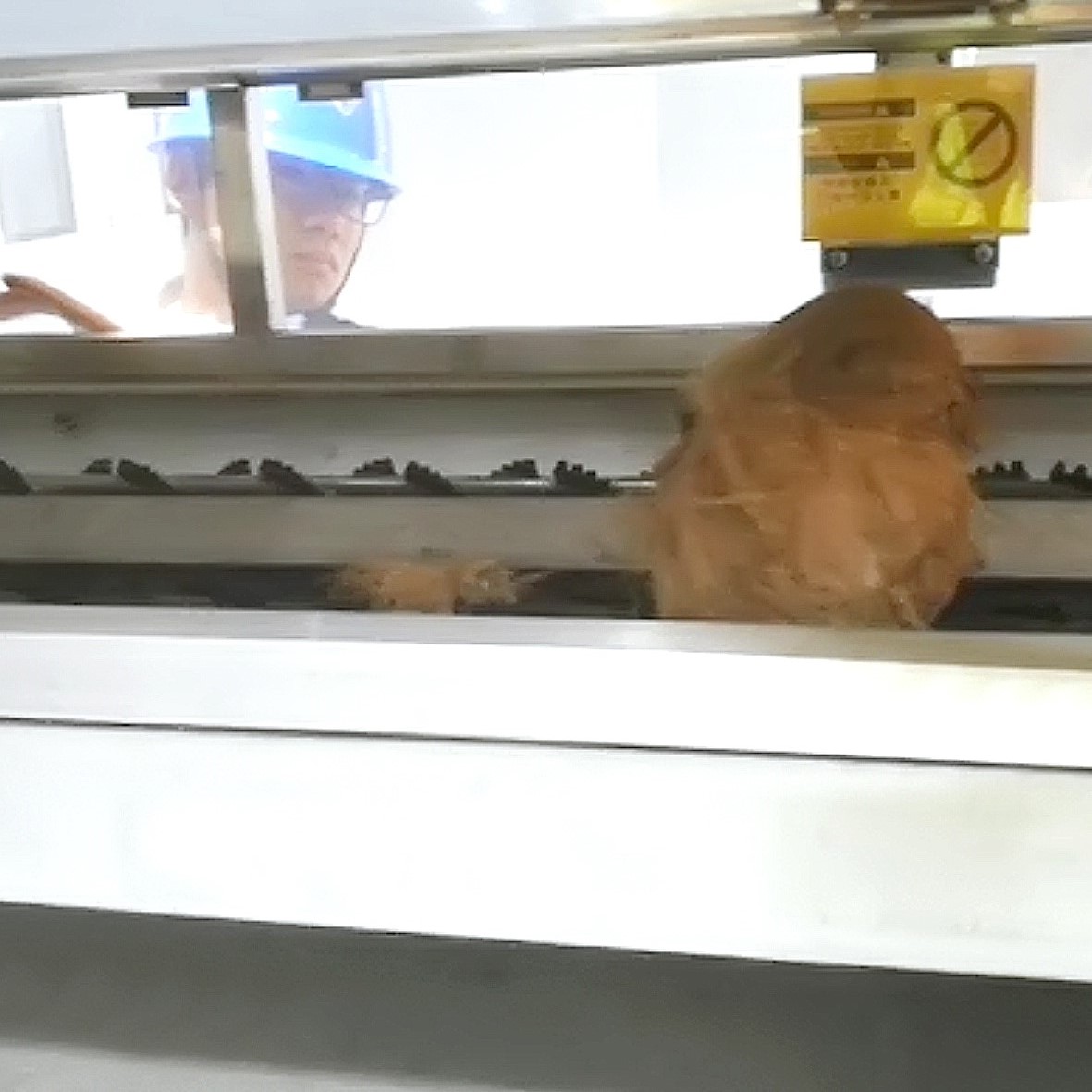

Coconut meat blanching machine

The crawler-type coconut meat blanching machine is composed of a stainless steel tank,a stainless steel baffle track,a steam heating interface,a cleaning port,a water outlet,a motor,a cooling sprinkler,a temperature control unit and other parts.The coconut meat is fed into the blanching tank.Driven by the crawler belt,the material is slowly moved towards the discharge port after being blanched and sterilized by high-temperature water.After the material discharge from the blanching tank,it is sprayed with cold water and transport to the sorting machine.

The whole machine is made of SUS304 stainless steel except for standard parts such as motors and bearings,which fully meet food hygiene requirments.The equipment is suitable for the pre-cooking process of coconut meat,Vegetables and fruits,and has good temperature control.The processes of feeding,moisturizing,cooking,and discharging can be operated continuously without interruption.It has the advantages of low labor intensity,high performance,easy operation,and labor-saving.

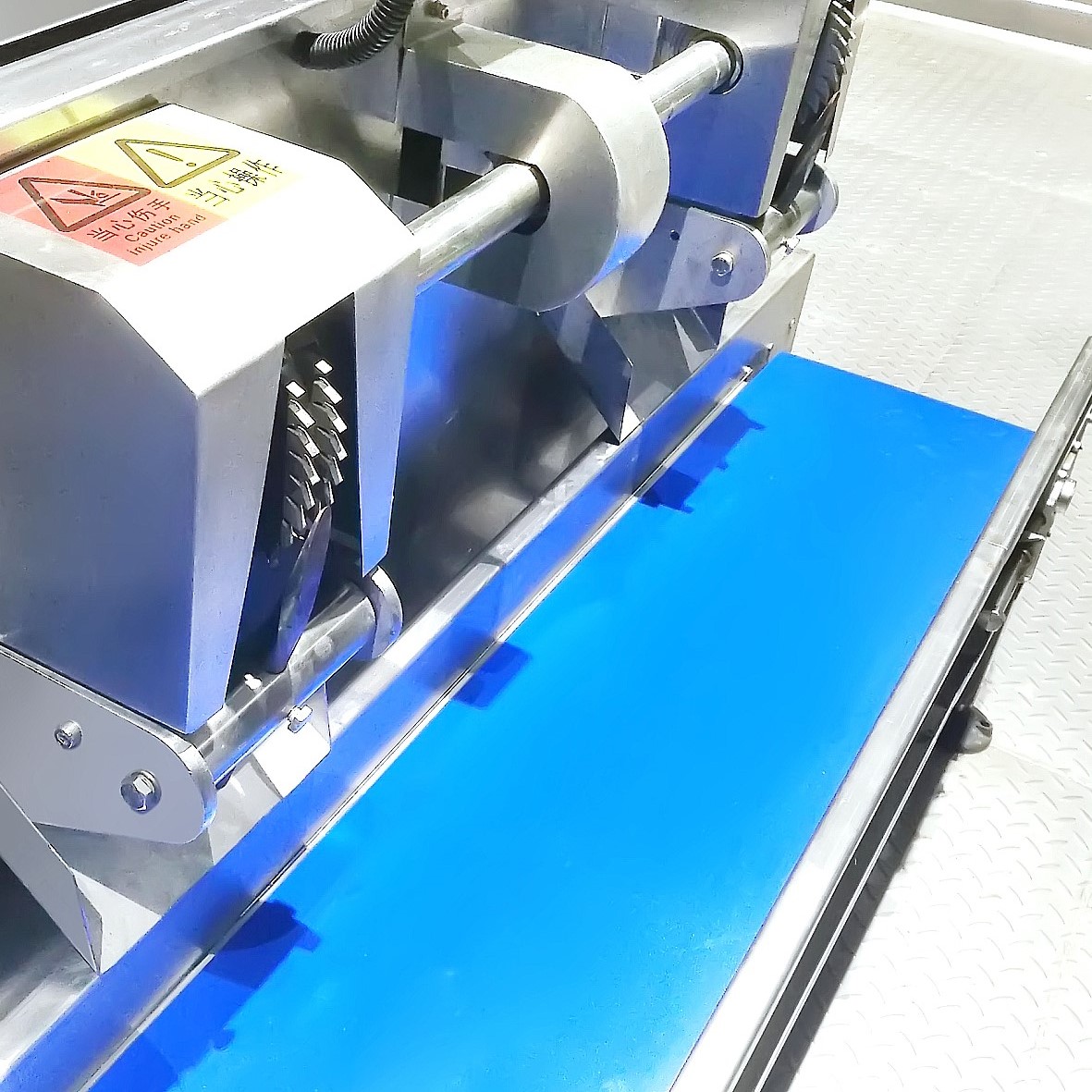

Coconut meat grinding machine

The coconut meat grinding machine consists of a feeding hopper,a sawtooth type converter,a frame,the main shaft,a bearing housing,a transmission,and a distcharge hopper.When the coconut meat enters from the feeding hopper,the coconut flesh is transferred to sawtooth by a tangential spiral and grinds the coconut meat into small particles(3-5mm).

Coconut milk extracting machine

There are two types of machines for coconut milk extracting:one is using belt press,the other is using double screw juice extractors.

The double screw type juice extractor usually has a higher yield rate than the belt press with about 55%-60%。The pneumatic double screw type extracting machine working principle:coconut kernel from the feed hopper led by screw.The cavity of the screw is smaller and smaller,press the coconut kernel,coconut milk is pressed out and collected into a vessel,the solid after extracted the coconut milk is discharged out through the interspaces between the screw and pressure regulating head.

The belt press coconut milk extractor is used for a higher capacity coconut milk processing plant.The coconut meat will be ground into flakes,and then feed into the belt press extractor.During extracting,the RO pure water will be added.

Coconut water and milk pasteurizer/sterilizer

There are two sterilizing processes during coconut water and milk processing.The first process uses plate-type pasteurizer to do pre-pasteurization(70-95℃ for 15-20 seconds)when extracting out the coconut water and milk,then storage into batch tanks instantly.The second process is that before coconut water and coconut milk filling,we use a tubular type UHT sterilizer(137-140℃ for 3-5 seconds)or DSI sterilizer to kill all the bacteria in the products.After sterilizing,the coconut water and milk can do aseptic filling into tetra pak cartons or hot filling into bottles or tin cans.

Coconut water and milk filler

There are three main products for coconut:single strength coconut water and coconut milk can do aseptic filling into aseptic brick cartons or hot filling into PET or glass bottles and small tin cans;Concentrated coconut water will be filled into aseptic bags in drums for repacking.

Custom solution for setting up a coconut milk processing plant. This plan covers key aspects such as site selection, equipment requirements, production processes, quality control, and environmental considerations.

Custom Solution for Coconut Milk Processing Plant

•Promotion: Use marketing strategies such as social media, trade shows, and sampling events to promote your product.