Classification by design pressure:

1、Low pressure:

0.1MPa≤P<1.6 MPa

2、Medium voltage:

1.6 MPa≤P<10 MPa

3、High pressure:

10 MPa≤P<100 MPa

4、Ultra high pressure:

P≥100 MPa

Classification by process function:

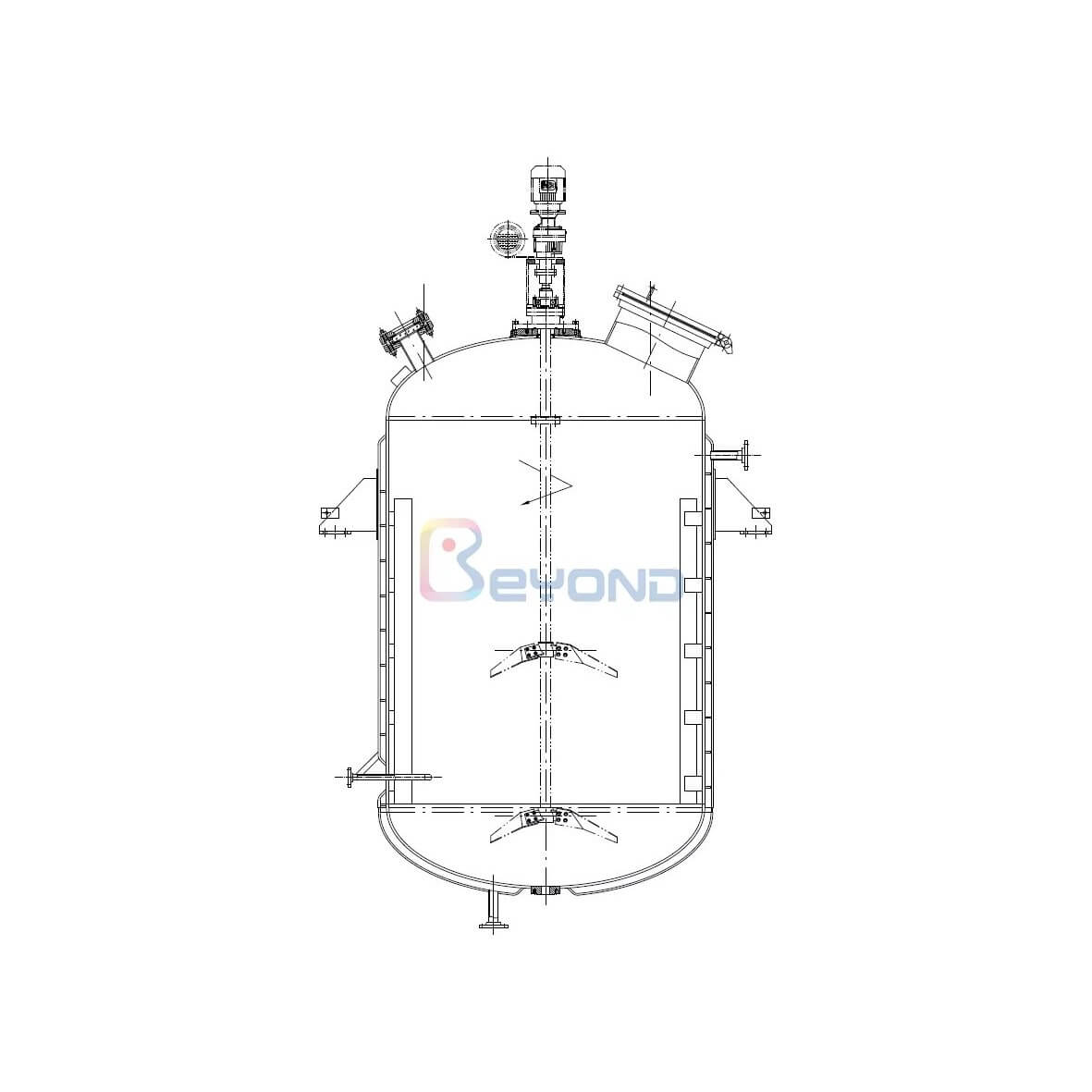

Reaction pressure vessel:

It is mainly used to complete the physical and chemical reaction of the medium. Such as reactor, reactor, decomposition pot, vulcanization tank, decomposition tower, polymerization tower, autoclave, ultra-high pressure reactor, synthesis tower, shift converter, cooking pot, steam ball, autoclave, gas generator, etc.

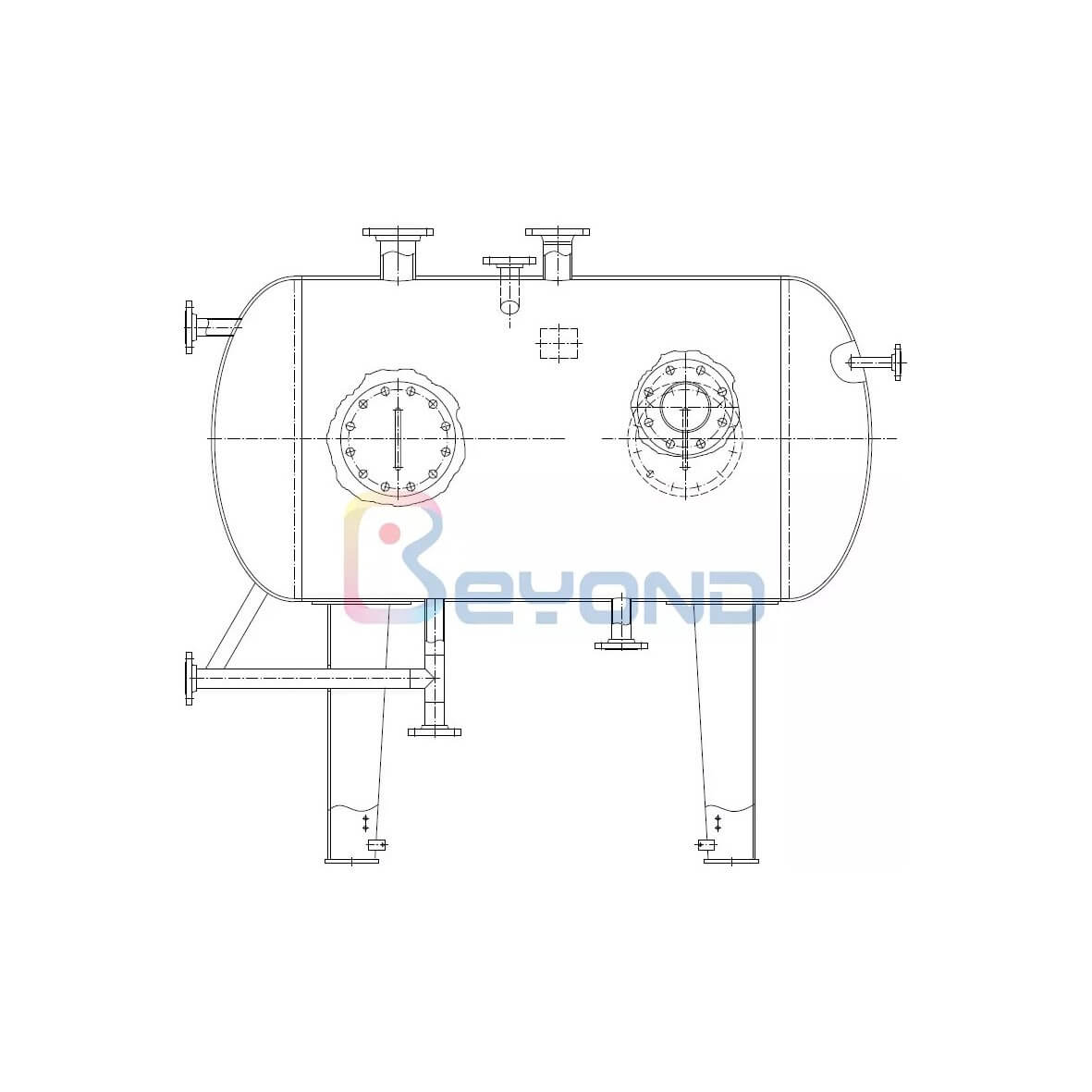

It is mainly used to complete the heat exchange of medium pressure vessel. Such as shell and tube waste heat boiler, heat exchanger, cooler, condenser, evaporator, heater, disinfector, Dyer, dryer, steamer, preheater, solvent preheater, steamer, steamer, steam generator, electric steam generator, water jacket of gas generator, etc.

Separation of pressure vessels:

It is mainly used to complete the medium of fluid pressure balance buffer and gas purification separation of pressure vessels. Such as separator, filter, oil collector, buffer, scrubber, absorption tower, copper scrubber, drying tower, stripper, distributor, deaerator, etc.

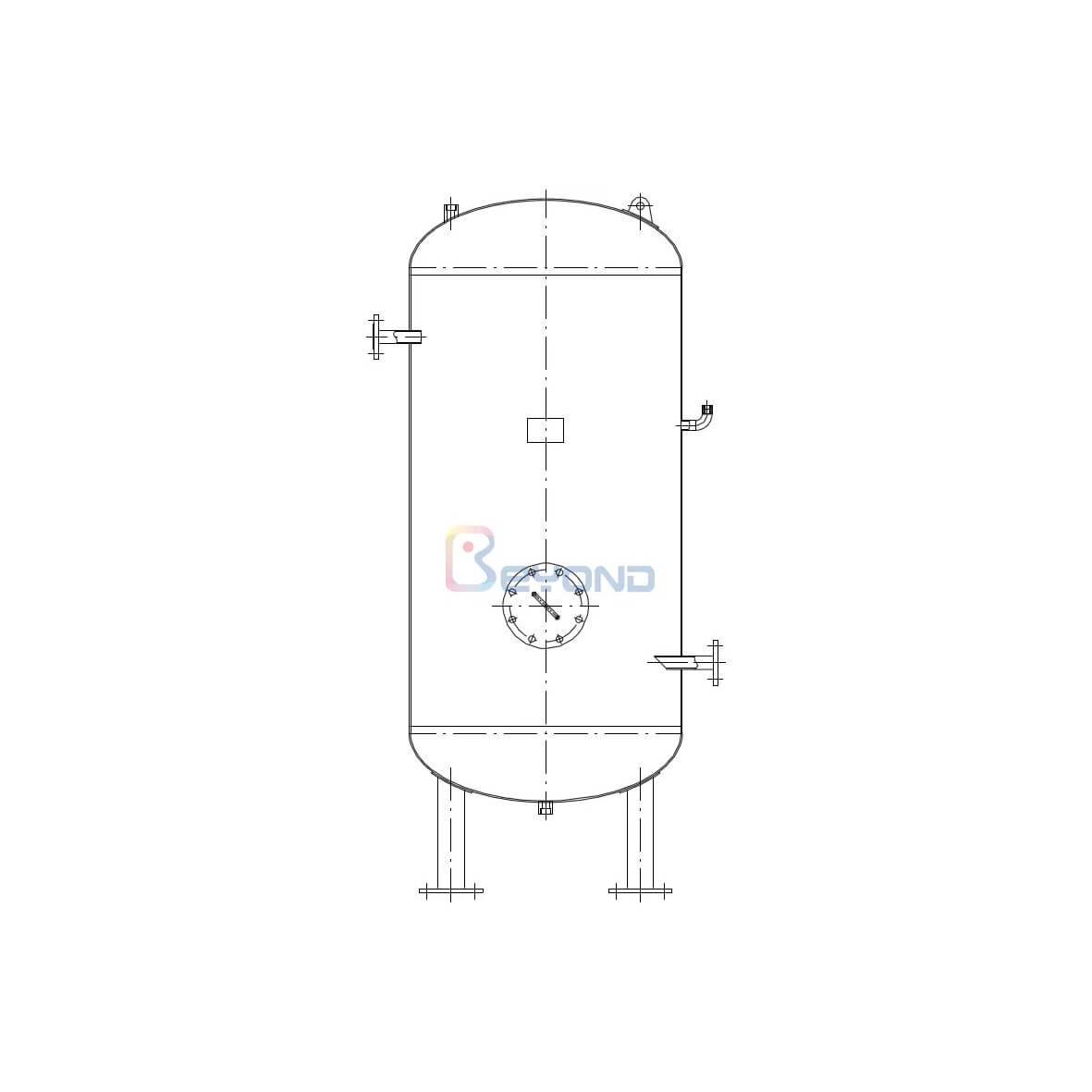

Storage pressure vessel:

It is mainly used to store, hold gas, liquid, liquefied gas and other media pressure vessels, such as various types of storage tanks.

Stationary pressure vessel:

The service environment is fixed and cannot be moved. There are many kinds of working media, most of which are toxic, flammable, explosive and corrosive chemicals. Such as spherical storage tank, horizontal storage tank, various heat exchangers, synthesis tower, reactor, dryer, separator, shell and tube waste heat boiler, manned container (such as medical oxygen chamber), etc.

Mobile pressure vessel:

Mainly used in the mobile, as a medium of packaging carried in the means of transport. Many working media are flammable, explosive or toxic. For example, the tank body of automobile and railway tank car.

Gas cylinder pressure vessel:

As a kind of pressure vessel, the social ownership is very large, including high-pressure gas cylinders (such as hydrogen, oxygen, nitrogen cylinders) and low-pressure gas cylinders (such as civil liquefied petroleum gas cylinders), many working media are flammable, explosive or toxic substances. It also has strong mobility, including long-distance movement in the process of transportation and short-distance movement in specific use. Such as liquefied petroleum gas cylinders, oxygen cylinders, hydrogen cylinders, nitrogen cylinders, carbon dioxide cylinders, liquid chlorine cylinders, liquid ammonia cylinders and dissolved acetylene cylinders.

Pressure vessel safety accessories:

1、Safety valve:

The function of the safety valve is to automatically open when the pressure in the equipment exceeds the specified requirements, release the excess pressure, and make the equipment return to the normal working pressure state. When the pressure is normal, the safety valve will close automatically. After the safety valve is calibrated, it is strictly forbidden to increase the setting pressure of the safety valve or make the safety valve invalid by means of adding heavy weight, moving heavy hammer or blocking the valve disc.

2、Pressure gauge:

The range of the pressure gauge should be suitable for the working pressure of the equipment, usually 1.5-3 times of the working pressure, preferably 2 times. A red line should be drawn on the dial of the pressure gauge to indicate the maximum allowable working pressure. There should be no water leakage or steam leakage in the connecting pipe of the pressure gauge, otherwise the indicated value of the pressure gauge will be reduced.

3、Bursting disc

4、Thermometers

5、Level gauge

6、Pressure reducing valve

7、Emergency cut-off device:

when the pipeline and its accessories are broken or misoperated, or when a fire accident occurs near the tank car, the valve can be closed in an emergency to quickly cut off the gas source, so as to prevent the spread and expansion of the accident.

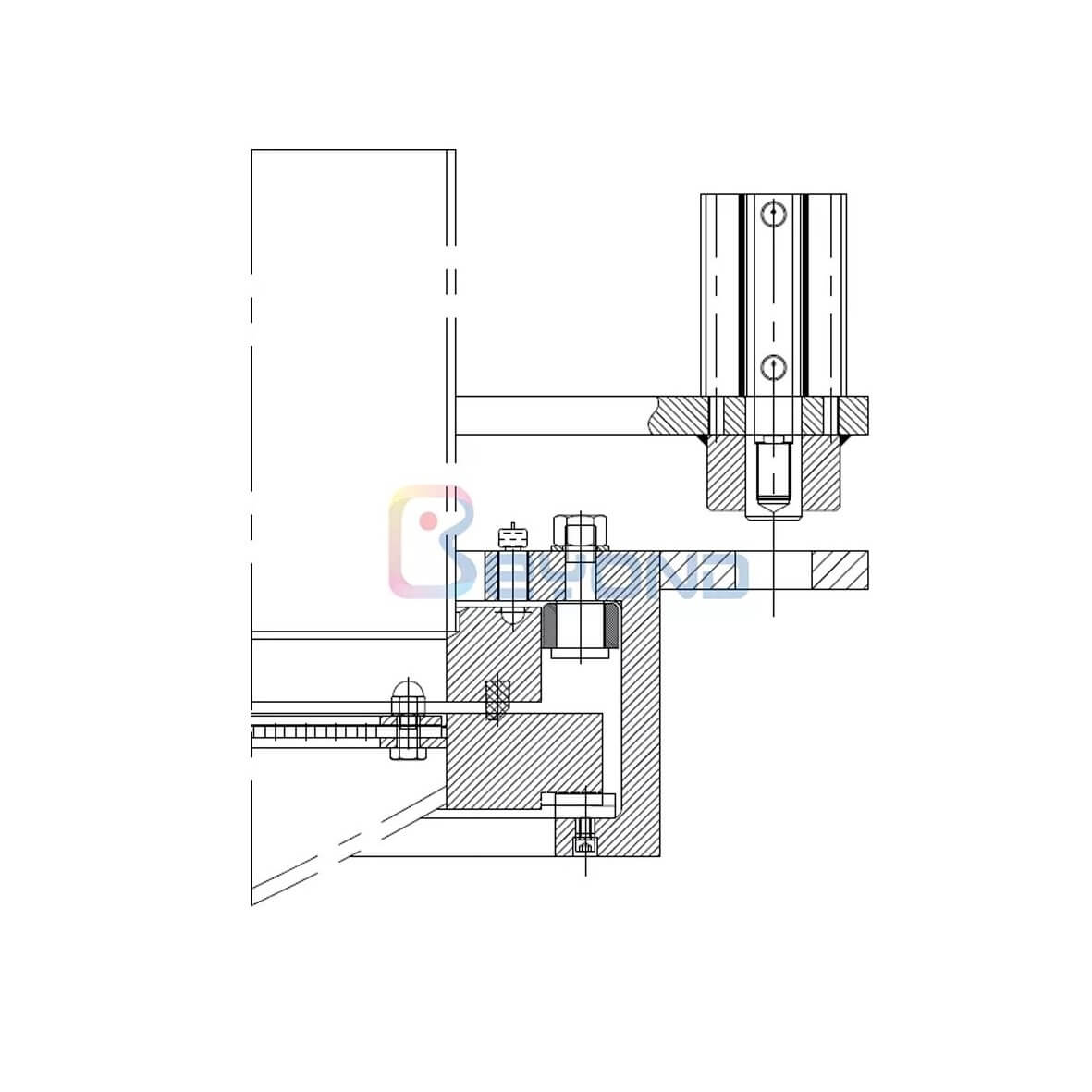

8、Safety interlock device of quick opening pressure vessel:

quick opening safety interlock alarm device is an effective measure to prevent operation accident of quick opening pressure vessel.

Its functions are as follows:

a. When the quick opening door reaches the predetermined closing position, it can boost the pressure and operate the interlocking control function;

b. When the internal pressure of the pressure vessel is completely released and the safety interlock device is disengaged, the quick opening interlock function can be opened;

c. It has alarm function synchronized with the above actions.