A butter processing line is a series of machines and equipment used to transform cream into butter. The line typically includes the following steps:

-

Cream separation: Raw milk is first separated into cream and skim milk. The cream contains the fat necessary for butter production.

-

Pasteurization: The cream is heated to a specific temperature to kill any harmful bacteria present.

-

Churning: The cream is agitated vigorously in a churn or separator, causing the fat globules to separate from the liquid phase.

-

Butter granule formation: As churning continues, the fat globules coalesce and form butter granules.

-

Butter washing: The butter granules are washed with cold water to remove any remaining milk solids and buttermilk.

-

Salt addition (optional): In some cases, salt is added to enhance flavor and act as a preservative.

-

Butter working: The butter is kneaded and worked to distribute the moisture evenly and improve texture.

-

Packaging: The butter is packaged into blocks, tubs, or rolls for distribution and sale.

Throughout the process, quality control measures such as temperature monitoring, fat content testing, and sensory evaluation are performed to ensure the butter meets the desired standards for taste, texture, and safety.

Butter mixer for mass production: The batch production butter mixer is composed of special-shaped mixing barrel, gear motor with brake, frame, support, safety guardrail, spray device, etc. the mixing barrel is horizontally equipped with stop rod. When the mixing drum rotates, the material will move from the bottom of the drum to the top. Due to its own weight, the material falls freely and collides with the stop rod and barrel wall, and a large amount of cream will be pulled apart and gathered from time to time to achieve the effect of making and mixing butter. Generally speaking, the filling amount of cream in the mixing bucket is about 50% of its total volume. The rotating speed of the mixing drum should not be too fast or too slow. The centrifugal force on the cream during rotation is slightly less than its own gravity, so as to facilitate the production and mixing of cream.

Direction for use

1. With jacket for heating and temperature keeping, or cooling to certain temperature for the milk become rigid ;

2. Parts contacting with product are all made of high grade stainless steel, comply with food grade sanitary standard.

3. With temperature control system, auto control the agitator, auto press the cheese to drain the milk whey

4. Evenly cutting and stirring, whey is highly separated.

-

Raw materials and products of butter processing line

1. Raw materials

The raw materials mainly used in butter processing line include dairy products and other auxiliary raw materials. The following is a detailed list of raw materials:

• Cream: The fat part extracted from milk is the main raw material for producing butter. The quality of cream directly affects the quality of the final product.

• Lactic acid bacteria starter: used to produce fermented butter, which gives the cream a special flavor through the action of lactic acid bacteria.

• Salt: used to produce salted butter, increase flavor and extend shelf life.

• Antioxidants: such as vitamin E, used to prevent butter from oxidizing and deteriorating.

• Flavors: such as natural vanilla flavor, used to increase the flavor of butter.

• Pigments: such as beta-carotene, used to adjust the color of butter to make it more attractive.

• Water: used for cleaning equipment and cooling process.

2. Products

The butter processing line can produce many different types of butter products. The following are some common product types:

• Unsalted butter: No salt is added, suitable for people who need to control sodium intake, and is also commonly used for baking.

• Salted butter: Add an appropriate amount of salt to increase flavor, suitable for direct consumption or cooking.

• Fermented butter: fermented by lactic acid bacteria, butter has a unique sour taste and flavor, and a richer taste.

• Organic butter: using organic milk and organic ingredients, following the standards of organic agriculture, without chemical pesticides and hormones.

• Low-fat butter: by reducing the fat content, it is suitable for people who pursue a low-fat diet.

• Plant-based butter: such as vegetable butter and margarine, suitable for lactose intolerance or vegetarians, usually made with vegetable oil and emulsifiers.

• Flavored butter: such as garlic butter and herb butter, by adding different spices and seasonings, a variety of flavor options are provided. -

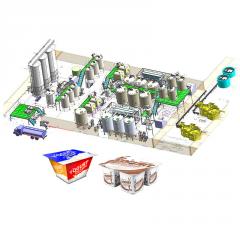

Designing a customized butter production line requires consideration of multiple aspects, including production processes, equipment selection, raw material and product characteristics, and the layout of the production line. Here is a detailed solution:

1. Preparation of raw materials for production process

• Reception and storage of raw milk: Receive fresh cream or whole milk and store it in a low-temperature environment.

• Pre treatment: Filter and centrifuge the raw milk to remove impurities.

Standardization

Fat content adjustment: Adjust the fat content in the raw milk through a centrifuge or other equipment to meet specific butter standards.

Pasteurization

Sterilization: Through high-temperature short-term treatment, harmful microorganisms are killed to ensure the safety of raw milk.

cooling

• Cooling: Quickly cool the sterilized raw milk to a suitable temperature to prevent bacterial growth.

Fermentation (optional)

Fermentation: For fermented butter, specific lactic acid bacteria fermentation agents are added for the fermentation process to enhance flavor.

stir

• Stirring: Send the cooled raw milk into a blender, and mechanically stir to gather fat particles and form butter lumps.

wash

• Washing: Wash the stirred butter chunks to remove excess whey and ensure the purity and taste of the butter.

Salinization (optional)

Salinization: Add an appropriate amount of salt to butter as needed to enhance flavor and shelf life.

Molding and Packaging

• Molding: Pour the processed butter into a mold or packaging container to form the desired shape.

• Packaging: Pack the butter to ensure good sealing and prevent contamination.

cold storage

• Refrigeration: Put the packaged butter into a refrigerated warehouse and keep it at 4-7 ° C to ensure product quality and extend shelf life.

2. Equipment selection: Main equipment

Raw milk receiving and storage equipment: storage tanks, cooling systems.

Pre processing equipment: filters, centrifugal separators.

Standardized equipment: centrifuges, standardized tanks.

Pasteurization equipment: plate heat exchanger, tube heat exchanger.

Cooling equipment: cooling tower, cooling tunnel.

Fermentation equipment (optional): Fermentation tank with temperature control system.

Mixing equipment: mixer.

Washing equipment: washing sink.

Salting equipment (optional): Salting machine.

• Forming and packaging equipment: forming machines, packaging machines.

• Refrigeration equipment: refrigerated storage.

3. Raw materials and product raw materials

Raw milk: Fresh, high-quality cream or whole milk.

• Fermentation agent (optional): Lactic acid bacteria fermentation agent, used to make fermented butter.

• Salt (optional): Used to make salted butter.

product

• Regular butter: Basic butter without additives.

Fermented butter: butter that has undergone fermentation treatment and has a unique flavor.

Salted butter: Add an appropriate amount of salt to butter to increase flavor and shelf life.

• Special flavored butter: butter with special flavors such as vanilla and garlic added.

4. Customized demand production capacity

Capacity selection: Select equipment with appropriate capacity based on the size and demand of the factory.

Flexibility: Design adjustable production lines to meet the production needs of different products.

Product diversity

Multi flavor production: Design production lines for multiple flavors to meet the needs of different markets.

Special requirements: Provide butter production lines with organic, salt free and other special requirements.

Degree of automation

• Automation level: Select different levels of automation equipment based on budget and management needs.

Information management: Introduce information management systems to improve production efficiency and management level.

Environmental requirements

Wastewater treatment: Design a wastewater treatment system that complies with local environmental regulations.

• Waste management: Reasonably handle the waste generated during the production process.

hygienic standard

GMP and HACCP: Ensure that all equipment and facilities comply with hygiene standards such as GMP and HACCP.

• Cleaning and maintenance: Regularly clean and maintain the equipment to ensure the hygiene of the production environment.

5. Design and plan the overall layout

Raw material receiving area: used for receiving and inspecting the quality of raw materials.

Storage area: used for storing raw materials and finished products.

• Processing area: including pre-treatment, standardization, pasteurization, cooling, fermentation (optional), stirring, washing, salinization (optional) and other processes.

• Packaging area: used for packaging and labeling of finished products.

Finished product storage area: used for storing finished products and preparing them for shipment.

• Laboratory: used for quality control and testing.

Office and Rest Area: Provides a place for employees to work and rest.

6. Technical support

Automation and informatization: Introduce automated production lines and information management systems to improve production efficiency and management level.

• Training: Regularly train employees to ensure they master the latest technology and operating procedures.

After sales service: Provide comprehensive after-sales service and technical support to ensure the normal operation of the production line.