Scope of application:

Pulp、vegetable pulp、concentrated pulp and materials containing particles、fibers、etc

Mainly used for aseptic filling packing types products, such as Tetra paper brick, Tetra paper Pillow, aseptic soft plastic bag, aseptic PET bottles, especially used for liquid milk and juice.

Technical:

(1)5℃→65℃(homogenizer)→137℃(3-5S)→20℃-25℃,for aseptic filling;

(2)5℃→65℃(homogenizer)→115℃/125℃(5-15S)→88℃-90℃,for hot filling;

(3)5℃→65℃(homogenizer)→115℃/125℃(5-15S)→75℃-78℃,for middle temperature filling;

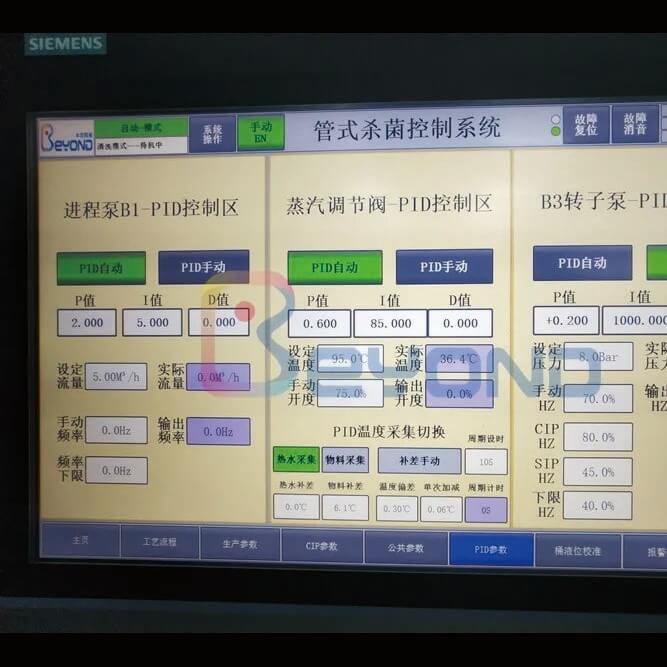

Siemens PLC Full-Auto control with touch screen

Equipment advantages:

Tube sterilization machine can be used to heat treatment of various liquid food and beverages, compared with other types of sterilization machine has the following advantages.

(1)Heating medium and material temperature difference is small, heat exchange tube using Four sets of tubes, heat exchange efficiency is high, less fouling, increased the working time of the sterilization machine.

(2)High degree of automation, from the equipment CIP cleaning, equipment suicide bacteria to material sterilization of the entire process can achieve automatic control, recording.

(3)Sterilization temperature control is accurate and reliable, steam pressure, flow, material flow, etc. are strictly automatic control.

All made by stainless steel, match the food sanitary standard.

(4)The material tube inner wall using advanced technology polishing and automatic welding, pipe design to achieve complete automatic cleaning, equipment whole process suicide bacteria, to ensure that the system aseptic.

(5)Strong system safety, system accessories are selected with good performance and high reliability of products, steam, hot water, materials, etc. have pressure protection measures and alarm system.

(6)High system reliability, the main components such as material pumps, hot water pumps, all kinds of valves, control system electrical components and executive components are world famous.

(7)Its own SIP system.

Equipment structure:

Overall structure

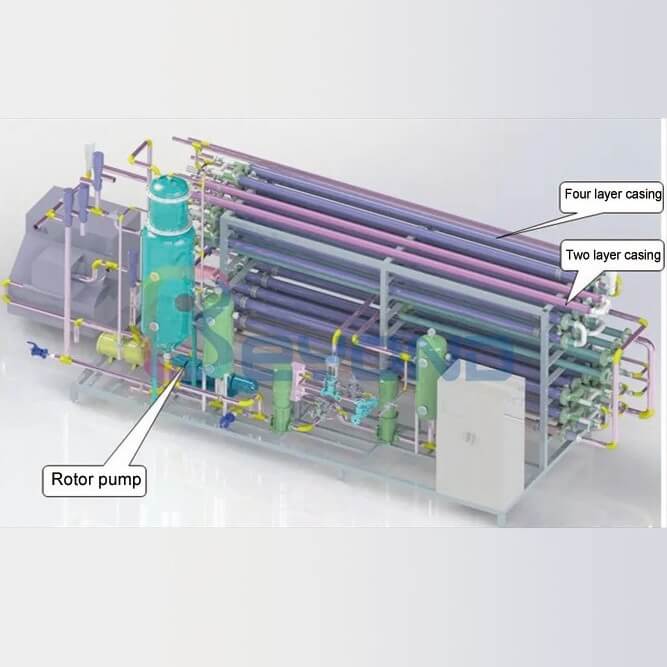

As shown in the figure, the equipment is mainly composed of heat exchangers, pumps, pipe valves, steam systems, electrical control systems, etc., the heat exchanger is divided into two layers (return cooling section) and four layers (heating, cooling section, heat recovery section)

Equipment characteristics:

It is used for heat exchange between media and materials. The materials are wrapped by the media on the upper and lower sides to form film heat transfer and improve the heat exchange efficiency.

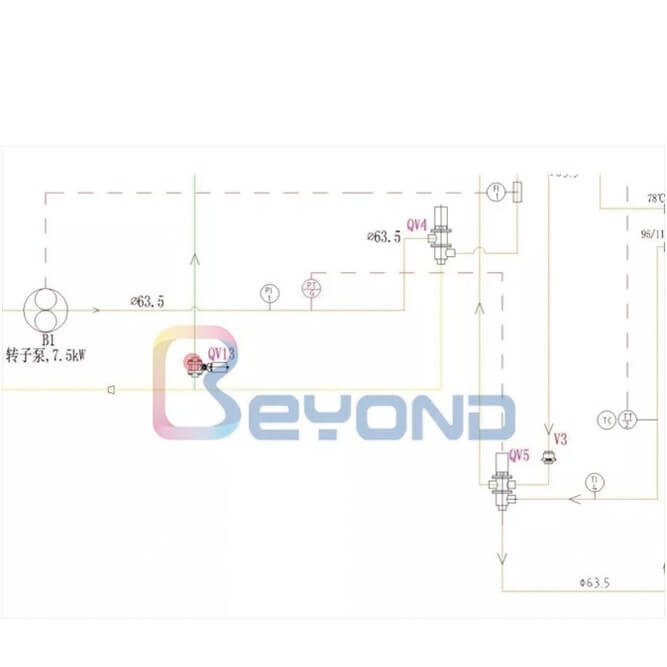

The casing sterilizer is different from the tubular sterilizer. When the materials flow, the pressure will act on the outside of the heat exchange pipe. At the same time, because the materials processed by the casing sterilizer generally have high viscosity and high pressure on the material side, the pump for conveying the materials is generally positive pressure pump (screw pump and rotor pump), so that the heat exchange pipe bears large external pressure. In order to prevent the damage of the heat exchange pipe under pressure (such as flat pipe), It is necessary to check the external pressure strength of the heat exchange tube.

Pt / G is a pressure sensor. When the set value is exceeded, it controls Qv5 to reverse, and the material returns to the balance drum to protect the rear pipeline.

The materials processed by the casing sterilizer generally have high viscosity and low heat transfer coefficient. The design material flow rate should not be too high to avoid excessive pipeline pressure. The material flow rate of the casing sterilizer is 0.3-0.5m/s; The width of material interlayer shall not be less than 13mm.

If you got any question about Casing sterilization machine , please contact Beyond service engineer freely.