Ultra high temperature sterilization and pasteurization are commonly used sterilization processes in dairy products. UHT sterilized milk is favored by countless consumers and manufacturers worldwide due to its long shelf life, no need for refrigeration, and good nutrient retention. In the mid to late 20th century, aseptic filling technology began to be commercialized, and it was widely applied and promoted in the aseptic packaging of liquid dairy products and liquid juice drinks. Aseptic tank equipment, as a temporary storage tank for sterile liquid products, is widely used in aseptic filling lines due to its characteristics of extending the continuous production time of the filling machine, avoiding the circulation heating of raw milk, and stabilizing the filling pressure. Especially when producing products with fruit granules, aseptic tanks must be used. This article takes aseptic cans as an example to introduce their structure and use, and summarizes their application advantages and quality control points in dairy processing.

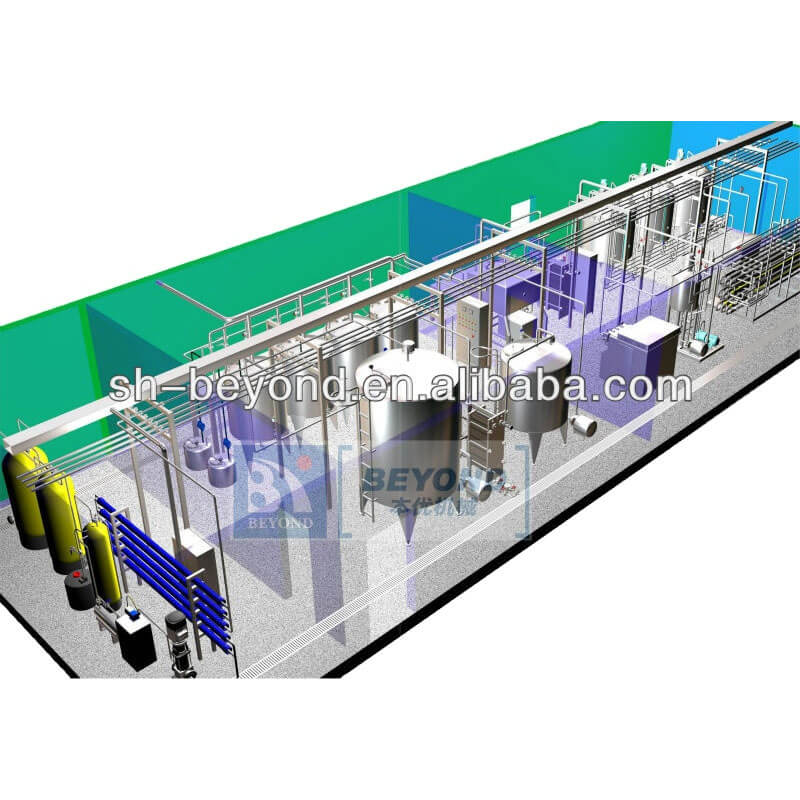

Sterile tank equipment can be used as a storage tank for sterile liquid products, connected to product sterilization and filling equipment (Figure 1), and used for intermediate storage of UHT processed dairy products. It is one of the key equipment in the sterile filling production line. Even if any of the machines undergo planned maintenance or cleaning, they can still continue production with the other party.

The emergence of sterile cans has played a good promoting role in the development of sterile filling technology. To ensure the integrity of the aseptic state of the product during storage, strict requirements are placed on the aseptic performance of the equipment. Some equipment has problems such as short aseptic time, unstable aseptic performance, low automation level, and low yield.

The sterile tank mainly consists of three parts: the tank body, valve group, and control cabinet. Figure 2 shows an overview of sterile cans and equipment used for product processing. The sterile tank adopts a modular design, mainly including the following 7 modules.

(1) Sterile cans. Store the product in a sterile state. The weighing sensor will weigh the tank body, the top level sensor controls the input valve to prevent overflow, the bottom level sensor measures whether there is still liquid in the sterile tank, and the tank top stirring device ensures that the product is in a flowing state to prevent sedimentation.

(2) Product input. The device controls the product from the sterilizer to the sterile tank, which is controlled by multiple pneumatic valves and protected from contamination by steam barriers. When the liquid level in the tank reaches 1 L, downstream products can be filled and transported for production; When the liquid level in the tank reaches a high level, UHT sterilized milk stops being transported to the tank.

(3) Cooling water input. After sterilization, the temperature of the tank body is reduced by filling the cooling interlayer with cooling water, and then discharged. The amount of cooling water used is 800 L/time, and each cooling requires 2 filling and discharge.

(4) Steam and CIP input. Steam ensures the steam supply during the sterilization process, used for sterilization of various pipelines and tanks, as well as the supply of steam barriers during the production process; CIP input ensures the supply of CIP solution during the CIP process.

(5) Steam and CIP output. Steam will be discharged in sterilization mode and CIP will be discharged in cleaning mode.

(6) Product output. This part ensures that the product is output from the tank body to the filling machine, and there is a temperature sensor at the bottom outlet of the tank to detect the product temperature; To ensure stable feeding of the filling machine, the pressure at the bottom of the tank remains constant, controlled by a pressure sensor at the bottom of the tank and a sterile air control valve group.

(7) Sterile air input. Used for supplying and discharging sterile air, there is a pressure sensor on the top of the tank that detects the pressure of the sterile air on the top.

2.2 Signal docking of sterile tanks

(1) Signal from sterilization machine and sterile tank. CIP (on-site cleaning); PAM (Product Signal); PDS (filling signal); RFP (Production Request Signal); RFW (Water Supply Request Signal); SPS (Production Stop Signal); SST (sterilization machine sterilization); WAM (Water Supply Signal); CSB (Clean Steam Barrier); RSB (flushing steam barrier).

(2) Sterile cans and filling machine signals. CIP (on-site cleaning); FST (filling machine sterilization); PAM (Product Signal); PFM (Filling Production Signal); RFP (Production Request Signal); RFW (Water Supply Request Signal); TST (Sterile Tank Sterilization); WAM (Water Supply Signal).

3.1 Sterilization mode

The whole product circuit is filled with steam, and the equipment and connected product pipes are heated and sterilized by saturated steam, including the sterile air filter. The temperature reaches 140 ℃ and remains for 1200 s. The temperature sensor at the tank bottom outlet will measure and monitor the sterilization temperature. After starting the sterilization program, the system automatically performs the following steps: preheating, pressurization, sterile air evacuation, sterilization timing, sterile air cooling into the tank, cooling water cooling into the interlayer, and manually selecting the sterile water flushing program to cool the tank and empty the sterile water. After the sterilization mode is completed, the machine will become sterile and ready for production.

3.2 Production mode

The sterile tank receives a PAM signal from the UHT, opens the product feed valve, and the product flows into the guided sterile tank from the UHT. After the filling machine sends a product request signal, open the product supply valve, and the product will be transported to the product input valve of the filling machine. There is a return pipeline from the downstream product pipeline of the filling machine to the sterile tank, and the valve group at the end of this pipeline is protected from contamination by steam barriers.

3.3 Sterile flushing mode

After producing a variety, before switching to another variety, the entire equipment will be rinsed with sterile water supplied by UHT to remove product residues, and sterile water can also be fed to the filling machine for sterile flushing. When the filling machine sends an RFW signal, the sterile tank will request sterile water from the sterilization machine; When the liquid level in the tank reaches the sterile flushing level, a WAM signal will be sent to the filling machine.

3.4 CIP mode

Alkali and acid cleaning agents are input into the equipment through the CIP pipeline, and the entire circuit is cleaned in a closed cycle according to the CIP process. The timing starts only after reaching the set temperature and conductivity. The cleaning circuit includes two paths: the tank body and the product pipe of the feeding valve. The CIP cleaning solution enters the tank from the top spray ball to clean the inner wall and supply pipe of the tank. After starting the CIP program, the system automatically performs the following steps: evacuation, pressurization, pre flushing, alkali washing, evacuation, water flushing, acid washing, evacuation, final water flushing, evacuation, and exhaust pressure relief.

3.5 standby mode

The equipment is in an open state, drained and cleaned, and there is no activation program. Sterilization mode must be activated before production can begin.

Application characteristics of 4 sterile cans in dairy processing

4.1 Enable the filling machine to produce continuously for a long time

In the entire UHT sterilization milk production process, UHT sterilization equipment is often a major factor limiting continuous production capacity. If equipped with sterile tank equipment, when upstream UHT equipment needs CIP cleaning for a certain period of production, the product is already stored in the sterile tank, and downstream filling machine equipment can continue to fill. When UHT is sterilized after CIP cleaning, sterile products can be transported to sterile tanks, and the filling machine can continue production, thereby increasing continuous production time, reducing cleaning costs, and increasing production.

4.2 Low furfuran content during the production of neutral milk such as pure milk

Furosine in dairy products is one of the series products produced by the Maillard reaction of protein and lactose under high temperature conditions. The lower the content of furosine, the better the nutritional quality of dairy products. In 1992, EU countries took furosine as an important indicator to judge the quality of dairy products. In 2004, the International Organization for Standardization (ISO) issued ISO 18329-2004 to detect the content of furosine in dairy products by High-performance liquid chromatography, and determine whether there is reconstituted milk by detecting the content of furosine in dairy products. In 2005, the original Ministry of Agriculture formulated the "Identification of Reconstituted Milk in Pasteurized Milk and UHT Sterilized Milk" (NY/T 939-2005), and in 2016, the revised version of the "Identification of Reconstituted Milk in Pasteurized Milk and UHT Sterilized Milk" (NY/T 939-2016) also included furfuran as an important indicator for detecting reconstituted milk, stipulating that every 100 g of protein in UHT sterilized milk contains more than 190 mg of furfuran, Or when the ratio of Lactulose content (mg · L-1) to furosine content (mg protein/100g) is less than 2 when the furosine content of UHT sterilized milk is 140 ~ 190mg per 100g of protein, it is identified as containing reconstituted milk.

In the process of UHT downstream direct connection filling machine producing pure milk and other neutral milk, if the downstream filling machine is in fault shutdown, the milk will flow back to the UHT system for cyclic heating. When the cyclic heating time exceeds a certain time, with the deepening of Maillard reaction, the color and flavor of the product will change significantly. If sterile tank equipment is installed downstream of UHT, this situation can be greatly avoided, because regardless of whether the filling machine is in production or malfunctioning, the product is always transported to the sterile tank and will not return to the UHT system for repeated heating. Therefore, when using sterile tanks, the content of furyl acid in the product is generally lower than that of products without sterile tanks.

4.3 No return milk loss

When milk cannot be filled for a long time, it will undergo multiple cycles of heating, resulting in significant changes in the color and flavor of the product. Industrial measures typically involve emptying the milk during this cycle of heating and re conveying the fresh milk to the UHT system, which can result in losses of several hundred kilograms of milk. If sterile tank equipment is installed downstream of UHT, this situation can be avoided and raw milk loss can be reduced.

4.4 Can produce products with fruit granules

Adding fruit granules to dairy products combines vitamin rich fruits and milk, which can achieve dietary balance, enhance the added value and customer experience of dairy products. Therefore, UHT dairy products with fruit granules are one of the products researched and developed by many dairy companies in recent years, but they also face problems such as uneven fruit granules and easy breakage of fruit granules. At present, there are two possible production processes for adding fruit grain dairy products: pre mixing process and post addition process. Both of these processes require the use of sterile tanks to temporarily store sterilized products. The stirring device on the top of the sterile tank ensures that the products are in a flowing state to prevent the accumulation of fruit particles, resulting in uneven fruit particles.

4.5 No need for frequent maintenance

Compared to filling machines and UHT equipment, sterile tanks have almost no moving or worn parts except for stirring paddles, so it is usually only necessary to regularly replace pipeline valve sealing rings, etc., without the need for large-scale periodic maintenance plans.

4.6 High degree of automation

Except for the need to disassemble the elbow joint when switching between production mode and cleaning mode, operators mainly complete the operation through the human-machine control panel. After selecting the required operation mode, all program steps will be automatically executed, with minimal manual intervention.

Quality control of 5 sterile cans in dairy processing

5.1 Steam must be clean

Due to the use of a large amount of steam during the sterilization process to sterilize the tank body, and the need to provide steam to maintain steam barrier during the production process, direct contact between steam and the product or its surface must be ensured to ensure that the steam meets food grade standards. In addition to installing steam filters, it is also possible to consider using a clean steam generator device to ensure steam cleanliness.

5.2 Replacement of sealing ring for mixing paddle shaft

During the production process, high-temperature steam is continuously injected into the mechanical seal of the mixing paddle shaft to prevent contamination of the product through the mixing shaft. However, the sealing components of the mixing shaft are often prone to aging at high temperatures, leading to a risk of product contamination in the tank.

5.3 Replacement of sterile air filter screen

Sterile air is compressed air that has been dehydrated and degreased, passing through two 0.01 μ The m level sterile air filter screen and pressure regulating valve are formed, and the sterile air filter must be steam sterilized before production begins. To ensure the filtration effect, regular replacement is necessary. It is recommended to use it 100 times under sterilization conditions of 140 ℃ and 30 minutes.

5.4 Ensure good CIP cleaning effect

CIP cleaning must thoroughly clean the tank and pipeline, and a reasonable cleaning procedure should be adopted. At the same time, appropriate cleaning agent concentration, temperature, time, flow rate and other parameters should be used to ensure the cleaning effect, especially when there are no dead corners in the mixing paddles.

5.5 Sterile air pressure

During the production process, the sterile air on the top of the tank needs to maintain a certain positive pressure to prevent the product from being contaminated by external air. When the pressure of the sterile air on the top of the tank is lower than the safety limit, it may lead to a risk of product contamination inside the tank.

5.6 Others

The sterile tank is in the downstream sterile process of UHT, and maintaining the sterility of the sterile tank is crucial. In addition, multiple factors such as equipment sterilization, steam barrier temperature, pipeline valve group leakage, storage time, etc. need to be considered. It is necessary to evaluate their respective risks and develop corresponding control measures to ensure product sterility.

In recent years, with the rapid development of the dairy and beverage industries, sterile filling technology has become increasingly mature, and the use of sterile cans has become increasingly widespread. At present, there is a large demand for sterile tank equipment in the Chinese market, and some domestic equipment manufacturers are also developing sterile tanks. However, there is still a certain gap in the aseptic performance and automation level of domestic sterile tanks compared to imported sterile tanks. Dairy enterprises should selectively equip aseptic cans based on their own product characteristics, processing technology, and production line layout, and develop reasonable quality control measures to ensure the aseptic state of products, thereby achieving the goal of extending continuous production time.

We specialize in turnkey engineering design and manufacturing of milk production lines, and our clients have achieved success in different countries around the world. Contact us now to obtain the latest milk processing line design plan and quotation!