Description:

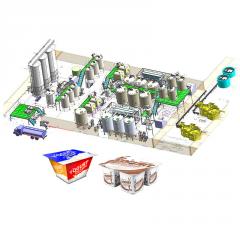

The almond milk production line is a sophisticated system designed to efficiently transform almonds into high-quality almond milk. This process involves several stages, each requiring specialized equipment to ensure optimal results. Advancements in technology have significantly improved the efficiency, sustainability, and safety of these production lines. Below is a detailed description of the key equipment involved in an almond milk production line.

Almond Milk Production Line Raw Materials and Products

1. Raw Materials

One

Almonds:

•

Quality requirements: High quality, mold free, and pest free almonds are the foundation for producing almond milk. Usually, choosing peeled or unsheathed almonds depends on market demand and product positioning.

•

Source: Almonds mainly come from major almond producing regions around the world, such as California, Spain, and Australia. Ensuring the freshness and quality of raw materials is crucial.

Two

Water:

•

Water quality requirements: Use purified water or filtered water to ensure the taste and safety of the final product. The ideal water quality should meet drinking water standards and be free of any harmful substances.

Three

Sweeteners (optional):

•

Type: May include natural sweeteners such as sucrose, maple syrup, agave syrup, honey, or artificial sweeteners such as erythritol and xylitol.

•

Function: Enhance the sweetness and flavor of the product to meet the taste needs of different consumers.

Four

Stabilizers and Thickeners (optional):

•

Types: guar gum, xanthan gum, carrageenan, etc.

•

Function: Improve the texture and stability of almond milk, and prevent layering.

Five

Vitamins and Minerals (optional):

•

Types: Vitamin D, calcium, iron, etc.

•

Function: Enhance the nutritional value of the product, making it closer to the nutritional composition of traditional milk.

Six

Essence (optional):

•

Type: Vanilla, Chocolate, etc.

•

Function: Increase the diversity of product flavors and attract more consumers.

2. Finished product

One

Almond Milk:

•

Form: Liquid plant milk, ranging in color from light beige to white, with a soft almond aroma.

•

Specifications: Common packaging includes paper boxes, plastic bottles, or glass bottles, with capacities ranging from 200 milliliters to 1 liter.

•

Shelf life: When unopened, it can be stored at room temperature for 6-12 months; After opening, it needs to be refrigerated and consumed within 7 days.

•

Usage: For various purposes such as direct consumption, cooking, baking, etc.

Two

By products:

•

Almond Pulp:

•

Usage: It can be used to make almond powder, baking ingredients, pet food, etc., achieving the maximum utilization of resources.

•

Wastewater:

•

Treatment: Wastewater generated during the production process needs to be treated appropriately, such as biodegradation or recycling, to reduce its impact on the environment.

Highlights of Almond Milk Production Line

The technical highlights of Almond Milk Production Line are reflected in multiple aspects, which not only improve production efficiency but also ensure product quality and safety. Here are several main technical highlights:

1. Efficient raw material processing technology

Automated cleaning and peeling system:

Use advanced automation equipment to clean and peel almonds, ensuring the removal of impurities and outer skin, and improving the purity of almonds. This process not only reduces labor costs, but also improves processing speed and quality.

• Precision grinding technology:

Using high-pressure micro jet or ultrafine grinding technology to make almond particles reach the nanometer level, thereby enhancing the taste and delicacy of almond milk. This technology can better release the nutrients in almonds, making the product more nutritious.

2. Intelligent control system

Fully automated production line:

The entire production line is highly automated, with intelligent control systems managing everything from raw material input and processing to finished product packaging. This not only improves production efficiency, but also reduces human errors, ensuring consistent quality of each batch of products.

Real time monitoring and data analysis:

The production line is equipped with various sensors and monitoring devices, which can monitor key parameters such as temperature, pressure, and flow in real time, and transmit the data to the central control system for analysis. Through big data analysis, production processes can be optimized to predict and solve potential problems in advance.

3. Advanced filtration and separation technology

Multi level filtration system:

Adopting a multi-stage filtration system, including coarse filtration, fine filtration, and ultrafiltration, effectively removes solid residues and impurities from almond milk, ensuring the purity and stability of the product. At the same time, the system can also retain beneficial components in almonds, such as vitamins and minerals.

Centrifugal separation technology:

Using a centrifuge for solid-liquid separation, almond residue and almond milk are efficiently separated, ensuring the quality of almond milk and achieving effective utilization of by-products. This technology significantly improves resource utilization and reduces production costs.

4. Aseptic filling and preservation technology

Aseptic filling technology:

Adopting aseptic filling technology, the filling operation is carried out in a completely enclosed environment, avoiding external pollution and ensuring the hygiene and safety of the product. Meanwhile, aseptic filling can also extend the shelf life of products and reduce the use of preservatives.

UHT (Ultra High Temperature Instant Sterilization) technology:

UHT technology can heat almond milk to high temperatures and rapidly cool it in a very short period of time, effectively killing harmful microorganisms while maximizing the retention of the product's nutritional content and flavor. The almond milk produced by this technology can be stored for a long time at room temperature, making it convenient for transportation and storage.

5. Environmental Protection and Sustainable Development

• Wastewater treatment and recycling:

The wastewater generated during the production process can be recycled after biodegradation or physical and chemical treatment, reducing water waste and minimizing environmental impact.

Energy saving measures:

By introducing energy-saving equipment and technologies such as heat recovery systems and solar power supply, the energy consumption of the production line has been reduced, carbon emissions have been reduced, and the company's sense of social responsibility and sustainable development concept have been reflected.

Through these technological highlights, modern almond milk production lines can not only produce high-quality, high value-added products, but also achieve energy conservation, emission reduction, and maximum resource utilization in the production process.

|

Equipment list DAIRY PRODUCTION plant (pasteurized milk\yogurt\cheese\cream\butter) |

||

| NO. | NAME | MAIN TECHNOLOGY PARAMETER |

| 1 | MILK RECEIVE\STORAGE\AND CREAM SEPARETOR UNIT | |

| 2 | Electron pound scale | maximum weighing 500KG |

| 3 | Milk weighing tank | made of SUS stainless steal,single layer,product feeded in through 40 mesh filter net,CIP cleaning ball |

| 4 | Milk acceptor | SUS304 stainless steel,single layer,CIP cleaning ball |

| 5 | Milk pump | SUS304 stainless steel,pump lift 24M,Hard Alloy Mechanical Seal,Inner Shell Bright-Polished |

| 6 | Twin piping filter | SUS304 stainless steel,two pipe,Stainless Steal Filter Element 100 Mesh |

| 7 | Dish separator | auto residue discharge |

| 8 | Chiling tank | SUS304 stainless steel,alveolate jacket,attached with compressor |

| 9 | Milk pump | SUS304 stainless steel,pump lift 24M,Hard Alloy Mechanical Seal,Inner Shell Bright-Polished |

| 10 | PREPARING UNIT | |

| 11 | Blending tank | SUS304 stainless steel,heat insulated,top off- center votical agitator,conical head,airtight manhole, breather valve,digital readout thermometer,anti-eddy baffle,supporters with adjustable feet |

| 12 | Milk pump | SUS304 stainless steel,pump lift 24M,Hard Alloy Mechanical Seal,Inner Shell Bright-Polished |

| 13 | Mini set of plate-type heat exchanger | SUS304 stainless steel,two stages, |

| 14 | High speed emulsification tank | SUS304 stainless steel,heat insulated,bottom high speed emulsifier,digital readout thermometer,supporters with adjustable feet |

| 15 | Milk pump | SUS304 stainless steel,pump lift 24M,Hard Alloy Mechanical Seal,Inner Shell Bright-Polished |

| 16 | Twin piping filter | SUS304 stainless steel,two pipe,Stainless Steal Filter Element 100 Mesh |

| 17 | Sterilizing,homogenizing unit | |

| 18 | UHT sterilizer | tub-type,sterilzing temperature 137 C,holding time 4S,full automatic control |

| 19 | High pressure homogenizer | 40MPa,(starting box included) |

| 20 | Temperature holding | SUS304,holding 300S |

| 21 | Distributing board | SUS304,3 holes |

| 22 | Cheese\butter processing unit | |

| 23 | Bufferying tank | SUS304 stainless steel,heat insulated,top off- center votical agitator,conical head,airtight manhole, breather valve,digital readout thermometer,anti-eddy baffle,supporters with adjustable feet |

| 24 | Milk pump | SUS304 stainless steel,pump lift 24M,Hard Alloy Mechanical Seal,Inner Shell Bright-Polished |

| 25 | Cream seperator | |

| 26 | Bufferying container | SUS304,with cover |

| 27 | Milk pump | SUS304 stainless steel,pump lift 24M,Hard Alloy Mechanical Seal,Inner Shell Bright-Polished |

| 28 | Butter-churner | SUS304,stepless timing |

| 29 | Cheese vat | SUS304,with heating jacket and insising device |

| 30 | Pressor | SUS304,6 heads |

| 31 | Mould | SUS304,10L,with cover |

| 32 | Yogurt fermentation unit | |

| 33 | Fermentation tank | SUS304 stainless steel,heat insulated,top off- center votical agitator,conical head,airtight manhole, breather valve,digital readout thermometer,anti-eddy baffle,supporters with adjustable feet |

| 34 | Rotary pump | SUS304 stainless steel,Hard Alloy Mechanical Seal,manual stepless shift |

| 35 | Plate cooler | SUS304,single stage,milk discharge at 4degreeC |

| 36 | Rotary pump | SUS304 stainless steel,Hard Alloy Mechanical Seal,manual stepless shift |

| 37 | Filling unit | |

| 38 | Higher position tank | SUS304 stainless steel,heat insulated,top off- center votical agitator,conical head,airtight manhole, breather valve,digital readout thermometer,anti-eddy baffle,supporters with adjustable feet |

| 39 | Pasteurized milk filling machine | |

| 40 | Yogurt filling machine | |

| 41 | CIP system | |

| 42 | Semi-auto CIP system | outer coat of SUS304 stainless steel material,inner shell of SUS316,single cleaning way,Concentrated acid/alcali tank adding system based on US technology, 100L×2 acid/alcali Concentrate tanks |

| 43 | CIP return pump | SUS304 stainless steel,pump lift 24M,Hard Alloy Mechanical Seal,Inner Shell Bright-Polished |

| 44 | Installation part | project installation and commissioning |

Customized almond milk production line process

Customizing an almond milk production line is a complex and multi-step process that involves various stages from demand analysis to final delivery. The following is the detailed customization process:

1. Needs assessment and planning

•

Requirement communication:

•

Have in-depth communication with customers to understand specific needs such as production scale, product positioning, budget constraints, etc.

•

Clarify the customer's production capacity requirements, production process preferences (such as whether to add sweeteners, stabilizers, etc.), environmental and sustainable development requirements, etc.

•

On site inspection:

•

Conduct on-site inspections of the customer's existing factory or planned construction site to assess whether the spatial layout and infrastructure conditions (such as water and electricity supply, drainage system, etc.) meet the installation requirements of the production line.

•

Preliminary scheme design:

•

Provide preliminary design solutions based on customer needs and on-site conditions, including production line configuration, equipment selection, process flow diagrams, etc.

2. Detailed design and engineering planning

•

Process design:

•

Determine specific production process parameters, such as grinding fineness, filtration level, sterilization method, etc., to ensure product quality and safety.

•

Design a reasonable production process, including raw material processing, mixing and blending, filling and packaging, etc., to ensure smooth connection between each process.

•

Equipment selection and layout:

•

Select suitable production equipment according to production process requirements, such as cleaning machines, grinding machines, filters, centrifuges, filling machines, etc., and arrange them reasonably to optimize space utilization and operational convenience.

•

Consider the level of automation, ease of maintenance, and potential for future expansion of the equipment.

•

Electrical and Control System Design:

•

Design a fully automated control system, including PLC programming, human-machine interface (HMI), sensor network, etc., to achieve real-time monitoring and intelligent management of the entire production line.

•

Plan the power supply system to ensure the safety and stability of equipment operation.

3. Procurement and Manufacturing

•

Equipment procurement:

•

According to the design plan, issue purchase orders to suppliers and select equipment and components with reliable quality and excellent performance.

•

Conduct technical review on key equipment to ensure compliance with design requirements and technical standards.

•

Manufacturing and assembly:

•

Manufacturing and assembling equipment in the factory, strictly following the design drawings and technical specifications for production.

•

Conduct quality inspection before leaving the factory to ensure that all performance indicators of the equipment meet the standards.

4. Installation and commissioning

•

Equipment installation:

•

Transport the production equipment to the customer's site and install it according to the design layout and installation manual to ensure correct installation of the equipment.

•

Strictly follow safety regulations during installation to ensure the safety of construction personnel and equipment.

•

System debugging:

•

Conduct comprehensive debugging of the entire production line, including single machine debugging, linkage debugging, load testing, etc., to ensure coordinated work between various equipment and normal system operation.

•

Timely solve problems that arise during the debugging process, adjust process parameters, and optimize production processes.

5. Training and Acceptance

•

Employee training:

•

Provide comprehensive technical training to customers, including equipment operation, daily maintenance, troubleshooting, etc., to ensure that customer employees can proficiently master the operation and management skills of the production line.

•

Provide detailed operation manuals and maintenance guides for customers' future use and reference.

•

Project acceptance:

•

Organize customers to inspect the production line and check whether all technical indicators meet the contract requirements.

•

Collect customer feedback, promptly rectify existing problems, and ensure that the production line meets customer needs and is smoothly put into operation.

6. After sales service and support

•

After sales guarantee:

•

Provide a comprehensive after-sales service system, including regular inspections, remote technical support, parts supply, etc., to ensure the long-term stable operation of the production line.

•

Establish a rapid response mechanism that can quickly resolve urgent issues raised by customers and reduce downtime.

Through the above customization process, we can create an efficient, intelligent, and environmentally friendly almond milk production line for our customers, ensuring that they have an advantage in market competition.