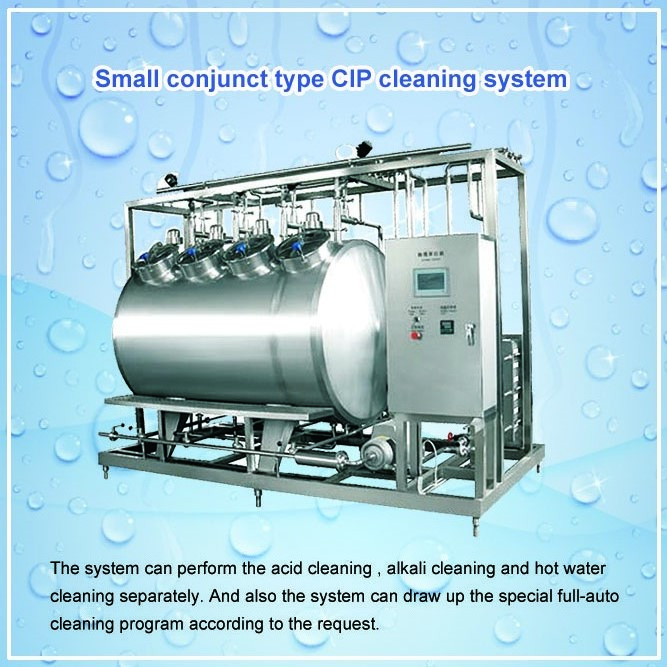

A small Union Type CIP (Clean-in-Place) system is a compact and portable cleaning system used in various industries, such as food and beverage, pharmaceutical, and dairy. It is designed to provide efficient and automated cleaning of process equipment, tanks, and pipelines without the need for disassembly.

The small Union Type CIP system typically consists of the following components:

Cleaning Solution Tank: A stainless steel tank that holds the cleaning solution, which is a mixture of water and cleaning agents or chemicals.

Pump: A high-pressure pump that circulates the cleaning solution through the system at a controlled flow rate. The pump ensures thorough cleaning and removal of contaminants.

Heat Exchanger: A heat exchanger may be included to heat the cleaning solution to the required temperature for effective cleaning.

Control Panel: A control panel with an operator interface that allows users to set and monitor the cleaning parameters, such as temperature, flow rate, and cleaning cycle duration.

Spray Nozzles: The system is equipped with spray nozzles strategically positioned to direct the cleaning solution to all areas of the equipment being cleaned. The spray nozzles generate high-pressure jets that remove dirt, residue, and bacteria.

CIP Return Pipeline: A pipeline that collects the used cleaning solution and returns it to the cleaning solution tank for recycling. This helps conserve water and reduces waste.

Sensors and Valves: Sensors and valves are used to monitor and control the flow of cleaning solution, temperature, and other critical parameters during the cleaning process.

The small Union Type CIP system is designed for easy installation and operation. Its compact size and mobility make it suitable for small-scale operations or facilities with limited space. It provides efficient cleaning, reduces downtime for manual cleaning, and ensures product quality and safety by removing contaminants effectively.

|

Type |

LTCIP-0.5X3 |

LTCIP-0.8X3 |

LTCIP-1X3 |

|

Outside specification: L × W×H |

3.2×1.4×1.6 |

5×1.8×2 |

≤0.45(T/H) |

|

Equipment weigh |

≈550kg |

≈650kg |

≈800kg |

|

Basic manually |

Inner shell:SUS304, δ3mm,outside shell: δ1.5mm,PU insulation material, coil tube to heat, single circuit. whole line bracket material: SUS304; manually controlling, flow rate: 10m3/h, pump lift:32m,power:3KW;Operating plate, Stainless Steel switch board. |

||

|

Semi-auto basic |

Inner shell:SUS304, δ3mm,outside shell: δ1.5mm,PU insulation material, coil tube to heat, single circuit. whole line bracket material: SUS304; manually controlling, flow rate: 10m3/h, pump lift:32m,power:3KW; imported temperature controller system from BURKERT,German. Operating plate, Stainless Steel switch board. |

||