A split type semi-auto CIP (Clean-In-Place) cleaning system is a type of cleaning system commonly used in industries such as food and beverage, dairy, pharmaceuticals, and cosmetics.

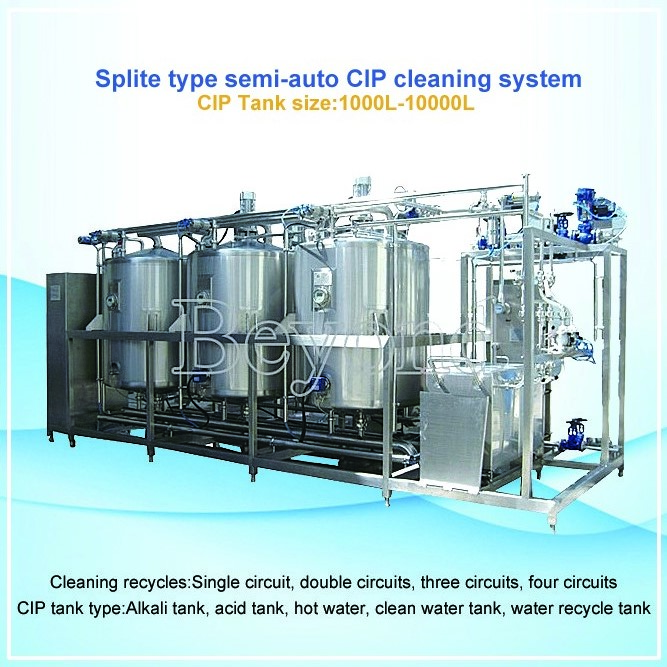

This type of CIP system consists of two main components: the cleaning tank and the circulation pump. The cleaning tank is used to hold the cleaning solution, which is typically a mixture of water and detergent or sanitizing agents. The circulation pump is used to circulate the cleaning solution through the various parts of the equipment or process system that needs to be cleaned.

The split type refers to the design of the CIP system, where the cleaning tank and circulation pump are separate units. This allows for more flexibility in the installation and operation of the system. It also allows for easy maintenance and cleaning of the system.

In a semi-automatic CIP system, some parts of the cleaning process are automated, while others require manual intervention. For example, the circulation of the cleaning solution through the system may be automated, but the operator may need to manually open valves, connect hoses, or select cleaning programs.

A split type semi-auto CIP cleaning system offers efficient and effective cleaning of equipment and process systems, ensuring high levels of hygiene and product quality.

Product quick details

Power(W): 100-200kw

Weight: Different size different weight/customized

Dimension(L*W*H): Different size different dimension/customized

Certification: CE&ISO

Warranty: 12 months/1 year

After-sales Service Provided: Engineers available to service machinery overseas

Main material: SUS304 or SUS316

Control type: automatic, semi-automatic

energy consumption: Low consumption with high efficiency

capacity: 500-10000L/H-customized

installation period: 1-3months

Period time: 30 days-120 days

Cups material: pouches, paper box, glass bottle, pet bottle, glass bottle

Product storage condition: room temperature; low temperature;

Technical parameter :

2. Temperature auto control;

3. Auto compensate the cip liquid level;

4. Auto compensate the liquid concentrate;

5. Cleaning liquids auto transfer;

6. Auto alarm

Related machinery of fruit processing line

Fruit storage silo-- Washing, sorting machine-- Grading/classifier machine

Squeeze extractor--Juice refiner-separator-evaporator-- Juice concentrate product

Fruit flesh/pulp collector-sterilizer--filling machine-fruit flesh

Essential oil refiner-fruit oil

Fruit residues collector-animal feed

Soaking extraction, pre-cooking, pulping, quick freeze, stemmer, ultra-filtration, decolor, destoner, crusher, stone washer, brusher washer, pine apple extractor, refiner, enzymolysis, filtration, CIP cleaning system

Related machinery of dairy(cheese, butter, milk, yoghurt,cream) processing line

Large outdoor storage tank, agitator tank, jacket tank, ferment growing tank, emulsification tank, milk weighing, milk receiving/collecting, extracting, pasteurizer yoghurt, UHT, HTST pasteurizer, plate pasteurizer, tubular UHT sterilizer, spraying type pasteurization, cooling tunnel, bottle tilting sterilization chain, CIP cleaning system, full-auto CIP, semi-auto CIP, evaporator, curd cutting, whey draining, cheese making, scalding/stretching/molding, cheese vat, mozzarella cheese, cheddar cheese, blending system, pre-pasteurization, cream separator system, powder melting, dissolving system, homogenizer system, turn-key project.