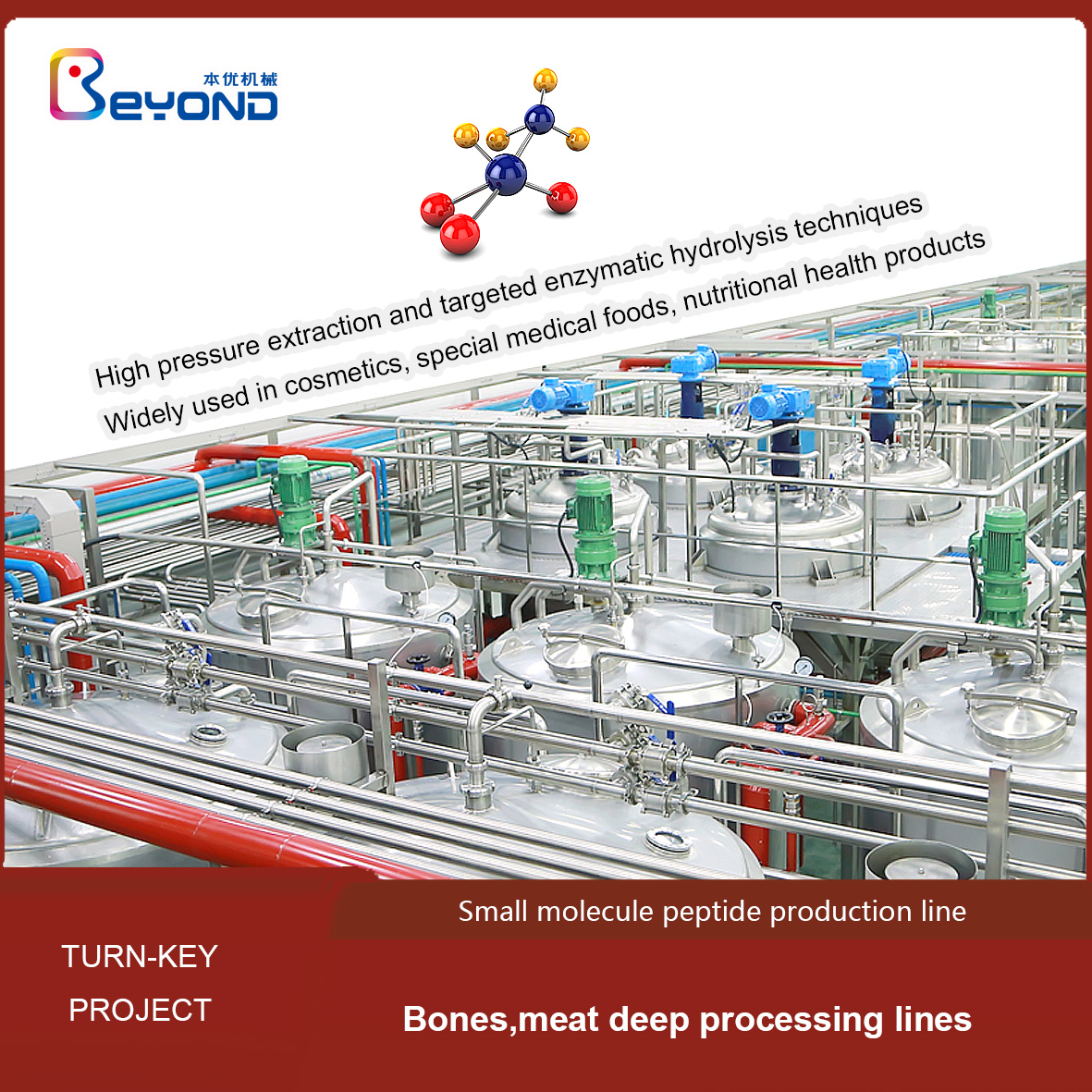

A small molecule peptide production line refers to a system or set of processes used for the synthesis and manufacturing of small molecule peptides. Small molecule peptides are short chains of amino acids, typically consisting of less than 50 amino acids.

The production line involves several stages to produce small molecule peptides in large quantities. These stages include:

Peptide Synthesis: This step involves the chemical synthesis of the peptide sequence using solid-phase peptide synthesis (SPPS) or liquid-phase peptide synthesis (LPPS) methods. The peptide synthesis can be automated and controlled by computer software.

Purification: After synthesis, the crude peptide mixture is purified to remove any impurities or by-products. Common purification methods include high-performance liquid chromatography (HPLC) or preparative chromatography.

Analytical Testing: Quality control and assurance tests are performed at various stages of production to ensure the purity, identity, and potency of the peptide product. Techniques such as mass spectrometry, nuclear magnetic resonance (NMR), and high-performance liquid chromatography (HPLC) are commonly used for analysis.

Formulation and Packaging: Upon successful purification and testing, the peptide is formulated into its final dosage form, such as a powder, solution, or lyophilized form. It is then packaged into appropriate containers with labeling and documentation for distribution.

Quality Control: The final product undergoes rigorous quality control checks to ensure compliance with regulatory standards and specifications. This includes testing for stability, sterility, potency, and other relevant parameters.

Storage and Distribution: The peptides are stored under appropriate conditions to maintain their stability and shelf-life. They are then distributed to customers, research laboratories, or pharmaceutical companies for further use or commercialization.

Throughout the production line, strict adherence to Good Manufacturing Practices (GMP) is crucial to ensure the safety, efficacy, and quality of the small molecule peptides.

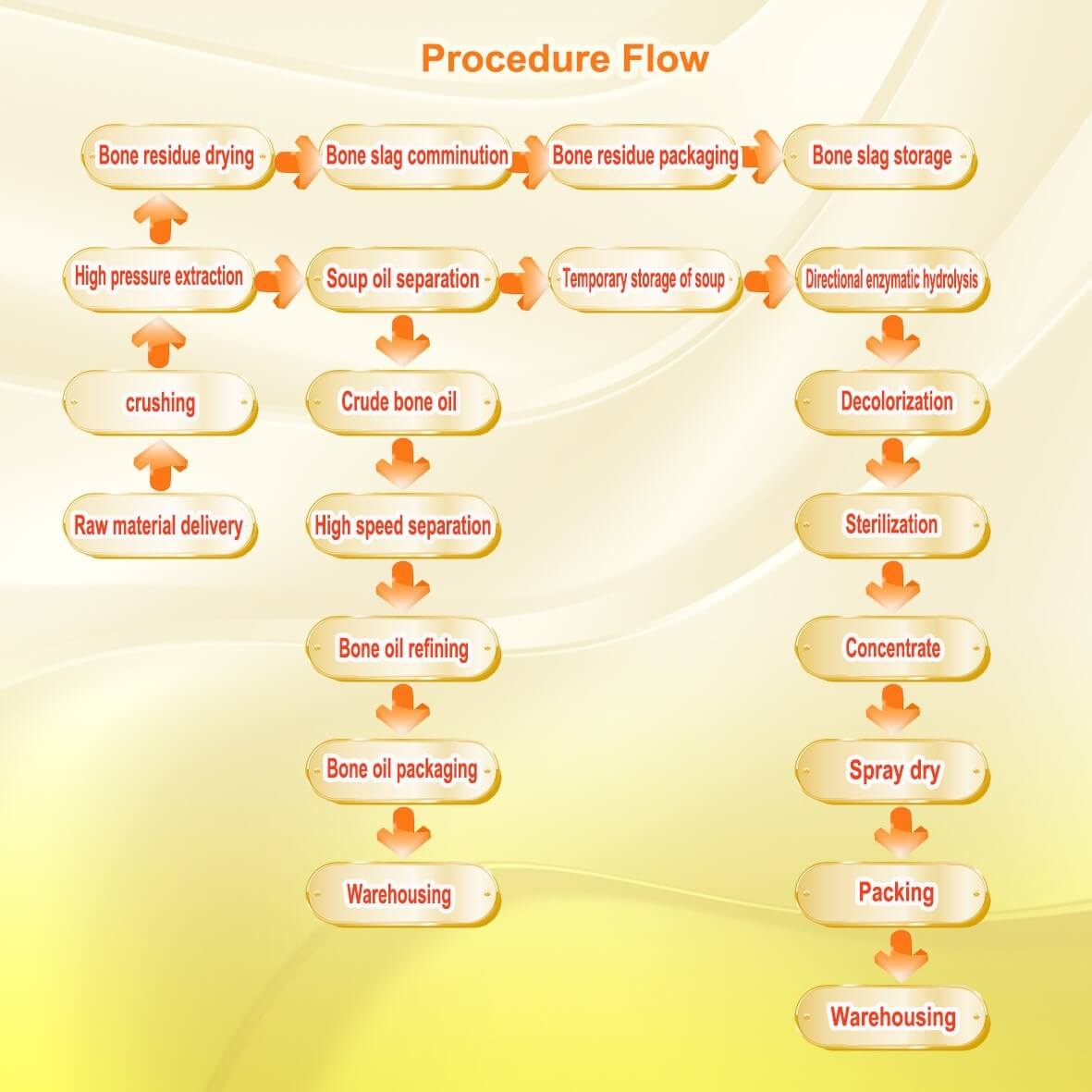

• Proccedure Flow

Raw material delivery→crushing→High pressure extraction→Soup oil separation-Temporary storage of soup→ Directional enzymatic hydrolysis→ Decolorization →Sterilization→Concentrate→Spray dry→Packing→Warehousing

Raw material delivery→crushing→High pressure extraction→Soup oil separation→Crude bone oil→High speed separation→Bone oil refining→Bone oil package→Warehousing

Raw material delivery→crushing→High pressure extraction→Bone residue drying→Bone slag comminution→Bone residue package→Bone slag storage