Bones and meat deep processing lines are specialized production systems designed to efficiently process bones and meat by-products obtained from animal carcasses. These production lines typically consist of several stages that work together to transform these raw materials into various products for different applications.

Raw Material Reception: Animal bones and meat by-products are received from slaughterhouses or other sources. The raw materials are inspected for quality and sorted according to their type and condition.

Cleaning and Washing: The bones and meat by-products undergo a thorough cleaning process to remove any dirt, blood, or residual tissues. This is typically done using water and sanitizing agents to ensure food safety.

Grinding and Pulverizing: The cleaned bones and meat by-products are then processed through grinding or pulverizing equipment to create a fine powder or paste. This step is essential for further processing and extraction of valuable components.

Extraction and Separation: Depending on the desired end products, various extraction methods are employed to separate different components from the ground bone or meat material. This may involve methods like centrifugation, filtration, or solvent extraction.

Drying and Dehydration: The extracted components, such as bone meal or meat powder, are dried or dehydrated to remove moisture content. This step helps in improving the shelf life of the products and reducing the risk of microbial growth.

Mixing and Forming: The dried bone or meat powders are mixed with other ingredients, such as binders, flavorings, or supplements, to create specific products. These mixtures are then formed into various forms, such as pellets, granules, or chunks, using specialized forming equipment.

Cooking and Sterilization: The formed products are cooked or subjected to a sterilization process to ensure food safety and eliminate any potential pathogens. This may involve heat treatment, pressure cooking, or pasteurization, depending on the specific requirements.

Cooling and Packaging: After cooking or sterilization, the products are cooled down to room temperature. They are then packaged in appropriate containers, such as bags, boxes, or bulk packaging, for transport and storage.

Quality Control: Throughout the production line, strict quality control measures are implemented to ensure the safety and quality of the bone and meat products. This includes regular testing, inspection, and adherence to regulatory standards.

It's important to note that the configuration and specific equipment used in bones and meat deep processing lines can vary depending on the intended products and scale of production. Manufacturers may also incorporate additional steps or technologies to meet specific market demands or comply with regulations.

• Application Scope

The bones and meat (of Chicken/Pig/Cow/Fish etc.)deep processing lines provided by Beyond company widely used in production of meat-product,bone soup,bone flavoring essence,pet feed,flavoring seasoning etc.

• Main composed processing system

Raw bones and meat grinding system;extraction tank system;water recovery system;soup separation tank system;concentrating system;preparing and sterilizing system;Maillard reaction tank system;Finished product storage system;filling system;residue broken bones treating system;electrical control system.

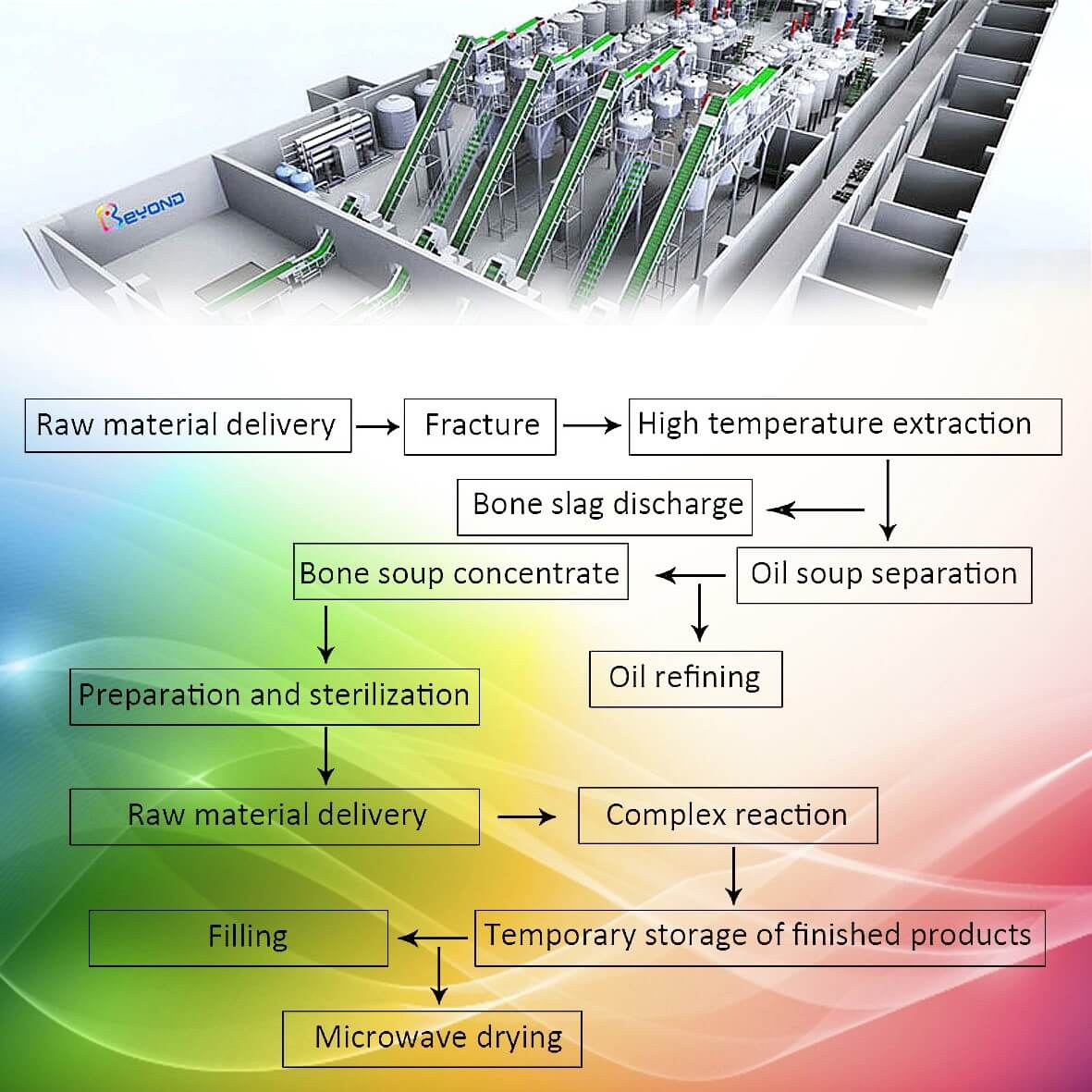

• Proccedure Flow

Raw animal bones/meat→Grinding→Pre-processing→ Extracting→ Separating →

Concentrating→Blending→Drying(Filling/Packing)→Finished Product

Introduction to Main Processing System

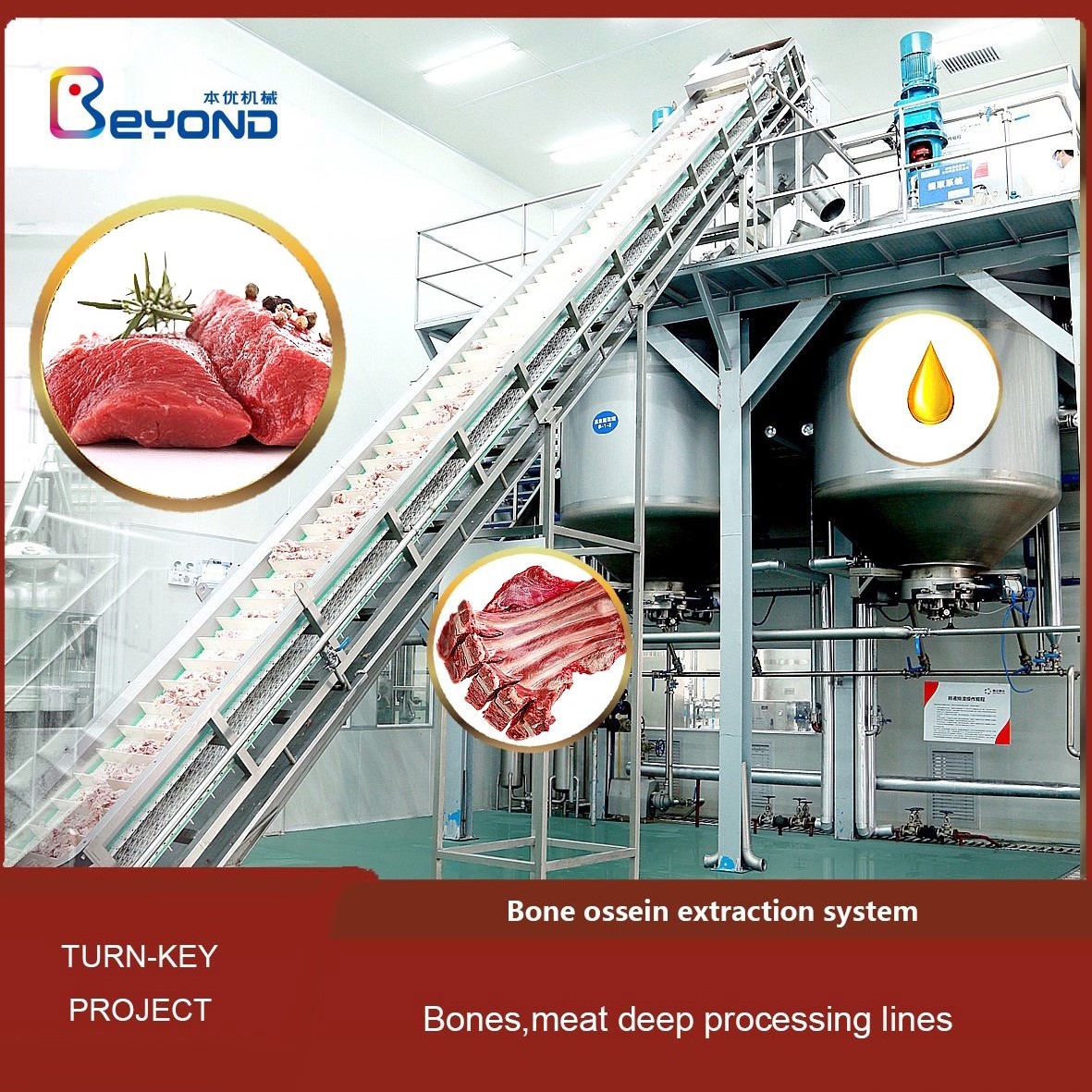

(A) Ossein Extraction Tank System

(1) Ossein extraction system applies to the nutrient content production using the by-products of Livestock and poultry bones as raw materials,adopting the technology of separation extraction,to extract the nutrient content in the livestock and poultry bones,such as Collagen protein,bone oil and mineral substance and so on.

(2) Advantages of ossein extraction tank system

•Short time extraction heating,high extraction efficiency;

•High pressure resistance,convenient feeding/discharging,high automatic level;

•All setting data(time/temperature)adjustable,flexible production arrangement;

•Integrated pneumatic valves group,advanced procedure,make sure clean thoroughly without sanitary dead angle;

(3)General bones ossein extraction tank design data

(take 12000L extraction tank as example)

•Volume:12000L ;

•Working pressure:inside working pressure 0.3Mpa,jacket working pressure 0.4Mpa ;

•Working temperature:134ºC ;

•Inside Material:meat;bones;water;steam;Jacket;

•Main structure:Vertical;triple layer with insulation;top and bottom conical cover;tank body incline type;smoothly rotation;accurate location;random angle stop;stainless steel protection device at the rotary part.

(B) High-efficiency Concentrating System

(1)Application Scope

This system is applicable in concentrating of all kinds of bone extracts solution.According to the content and physico-chemical property of bone extracts solution.We adopt the technology of membrane filtration or MVR to achieve the separating and concentrating the bones extract,and produce the bone products with high additional value.

(2)Performance Characteristics

• Stable working;energy-saving;low steam consumption;

• High concentration factor;short concentration time;

• Workable for heat sensitive material;

• High heat transfer coefficient,preventing the "Drywall" phenomenon

(C) Maillard Compound Reaction Tank System

(1)Operating Principles

Firstly turn on the stirrer motor and reducer,under the drive of stirring shaft rotary,the scrapper stirrer;propeller,frame stirrer will all start rotary.

The Polystyrene plate connected with spring installed on the scrapper stirrer sweeps the material stick on the inner tank wall,between the level beam of frame stirrer and the shaft has 45 degrees angle,which will form pushing force.

Input solid material after the stirrer starting,otherwisethe solid material may deposit to the dead angle under the stirrer supporting bearing,the bottom sectorial scrapper can blend the material to dissolve it evenly.Afterwards turn on the steam,the steam heats the product inside tank through the jacket baffle plate and jacket covers,the condensate water is discharged through the condensate outlet.Observe the temperature of the probe,adjust the stirrer speed and direction,Turn off the steam after the reaction finisshed,open the bottom valves to discharge.After discharging,turn on the CIP cleaning ball to clean the tank inside surface,all reaction procedures finish.

(2)Characteristics

•Continuously feeding,auto discharging,high reaction efficiency;

•Compound stirring system,easy to clean,product not easy to get coked;

•Aroma recycle device can collect the aroma produced during the reaction process

Product Specifications

|

Condition |

New |

|

Brand name |

Shanghai Beyond; |

|

Type |

whole processing Line/turnkey project/bones and meat processing line |

|

Voltage |

220v/380v |

|

Power(W) |

100-200kw |

|

Weight |

Different size different weight/customized |

|

Dimension(L*W*H) |

Different size different dimension/customized |

|

Certification |

CE&ISO |

|

Warranty |

12 months/1 year |

|

After-sales Service Provided |

Engineers available to service machinery overseas |

|

Main material |

SUS304 or SUS316 |

|

Control type |

automatic, semi-automatic |

|

energy consumption |

Low consumption with high efficiency |