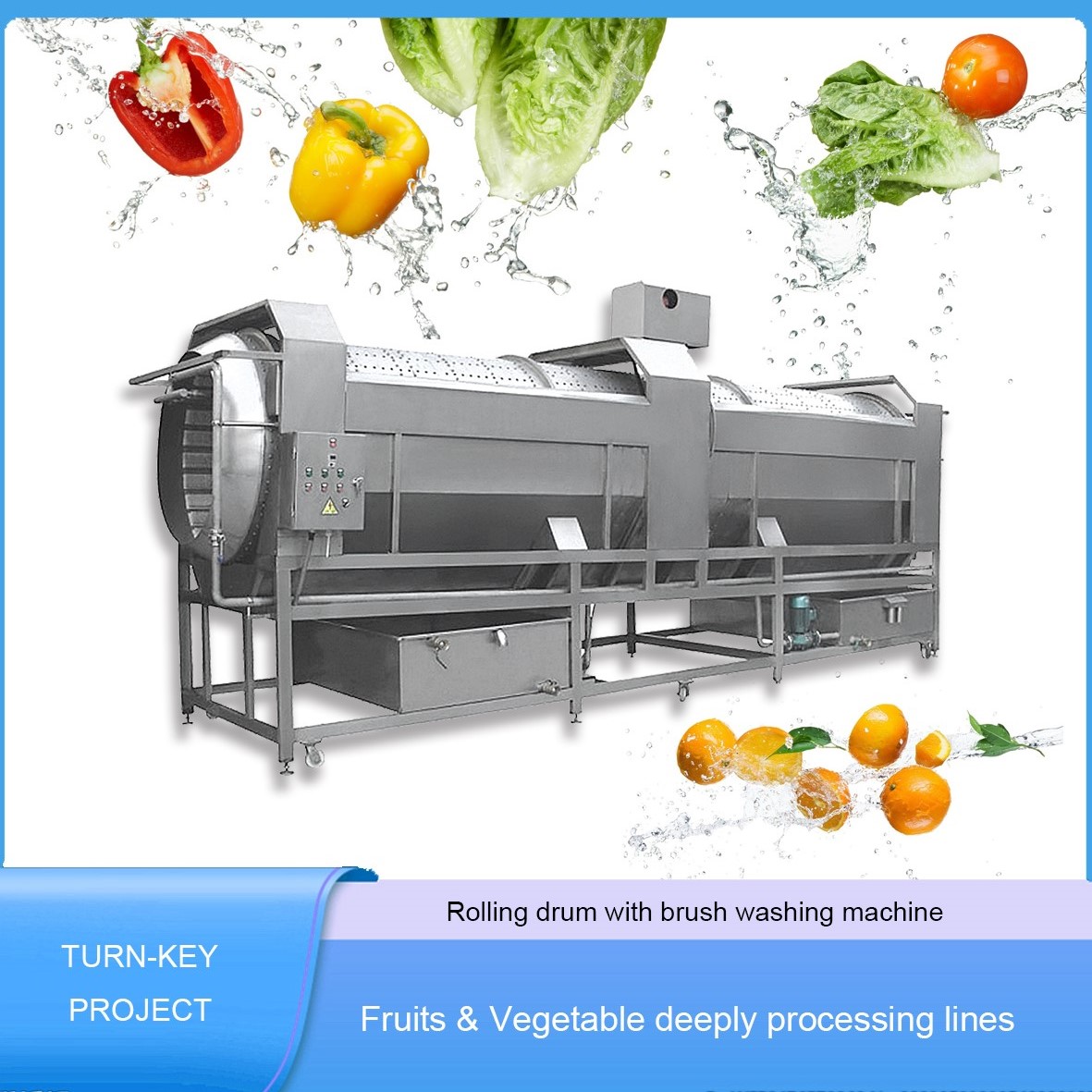

Rolling Drum With Brush Washing Machine, also known as a drum washing machine, is an automated device used for cleaning items. This equipment mainly uses a drum brushing method to clean items, which has the advantages of good cleaning effect, high efficiency, and easy operation.

The main components of a drum washing machine include a motor, reducer, drum, brush, etc. The motor drives the reducer to rotate the drum, causing the brush to rub and clean the items inside the drum. This equipment is usually used to clean food ingredients such as vegetables, fruits, meat, etc. It can also be used to clean other items such as textiles and ceramic products.

The drum washing machine has the following characteristics:

Good cleaning effect: Roller brushing can effectively remove dirt, pesticide residues, bacteria, etc. from the surface of items, ensuring cleaning quality.

Efficient and energy-saving: The operating speed of the equipment can be adjusted according to the cleaning needs of different items, saving energy.

Easy to operate: Automatic control, the operator only needs to put the item into the drum and press the start button to complete the cleaning process.

Safety and hygiene: The equipment is made of stainless steel and meets food safety and hygiene standards; At the same time, the device has functions such as overload protection to ensure safe operation.

Strong adaptability: The drum washing machine is suitable for cleaning items of various shapes, sizes, and materials, and has strong adaptability.

Widely used in food processing industry, catering industry, fruit and vegetable market and other fields, it improves the efficiency of cleaning work, ensures cleaning quality, and reduces cleaning costs. In addition, drum scrubbing machines can also be used in industries such as medicine, chemicals, textiles, etc. to clean related items.

Description:

Fruit elevator transports the fruits by moving the clapboard up under the drive of motor.

Construction Type: horizontal and gradient; just gradient.

Material of the clapboard: Supporter is made of SUS304-2B stainless steel; the clapboard is made of stainless steel or plastic PP (polypropylene), which is applicable for all kinds of fruits and vegetables.

Fruits can be feed or discharged into the lifter at any points of the machine.

Technical Parameter:

|

Name |

Technical |

Transportation capacity |

Motor power (kw) |

|

|

GBTS-S400 |

The Supporter and the clapboard are all of SUS-304 stainless steel, moving speed is adjustable by stepless |

line speed0.1-0.4m/s capacity 2.5-4m³/H |

2-5m |

0.55 |

|

6-10m |

0.75 |

|||

|

GBTS-S600 |

The Supporter and the clapboard are all of SUS-304 stainless steel, moving speed is adjustable by stepless |

(line speed)0.1-0.4 m/s (capacity)4-6m³/H |

2-5m |

1.1 |

|

6-10m |

1.5 |

|||

|

GBTS-S800 |

The Supporter and the clapboard are all of SUS-304 stainless steel, moving speed is adjustable by stepless |

(line speed)0.1-0.4 m/s (capacity)6-8m³/H |

2-5m |

1.5 |

|

6-10m |

2.2 |

|||

|

GBTS-S1000 |

The Supporter and the clapboard are all of SUS-304 stainless steel, moving speed is adjustable by stepless |

(line speed)0.1-0.40 m/s (capacity)8-10m³/H |

2-5m |

1.5 |

|

6-10m |

2.2 |

|||

|

GBTS-S1200 |

The Supporter and the clapboard are all of SUS-304 stainless steel, moving speed is adjustable by stepless |

(line speed)0.1-0.4 m/s (capacity)10-15m³/H |

2-5m |

1.5 |

|

6-10m |

3 |

|||

|

GBTS-S1400 |

The Supporter and the clapboard are all of SUS-304 stainless steel, moving speed is adjustable by stepless |

(line speed)0.1-0.4 m/s (capacity)15-20m³/H |

2-5m |

2.2 |

|

6-10m |

4 |

|||