The fruit and vegetable brush cleaning machine is an automated device used to clean vegetables and fruits. It is mainly composed of a motor, gearbox, brush roller, etc. It has the characteristics of large cleaning volume, high efficiency, low energy consumption, and simple operation. The brush cleaning machine adopts the principle of imitating manual cleaning for cleaning, which can effectively remove dirt, agricultural residues, and sediment on the surface of fruits and vegetables.

The brush cleaning machine is suitable for cleaning various round and oval fruits and vegetables, such as ginger, carrots, yams, potatoes, sweet potatoes, kiwifruit, and other root tuber vegetables. In addition, it can also be used to clean granular, leaf like, and root like products such as fruits and seafood.

The equipment material is generally stainless steel SUS304/2B, which meets the hygiene requirements for exported food. During the cleaning process, the equipment uses a bubble generation device to cause the material to tumble and enhance the cleaning effect. At the same time, an appropriate amount of medication can be added for disinfection and color fixation. The cleaned floating debris overflows from the overflow tank, and the sediment is discharged from the sewage outlet to achieve the purpose of cleaning.

The brush cleaning machine has the advantages of beautiful appearance, convenient operation, and long service life. Widely used in food processing factories, vegetable processing centers, and other places to improve work efficiency and ensure food safety.

The equipments is composed of SUS304 stainless steel tubes as bearing and with brush on the tubes to wash the fruits and

vegetables. The stainless steel tubes make the brush circumvolve, the neighbor hood brushes make the fruits and vegetables

circumvolve and to be washed, meanwhile the bad fruits and vegetables will be picked up manually.

Main characteristics

The frame adopts the whole frame integral welding structure, the overall rigidity is good, and little vibration.

The entire machine is in compact structure and reliable operations; the optimized designs are made on each component, making it easier to clean and replace.Fully made of stainless steel, in accordance with food hygiene standards.Can be installed on the assembly line, automatic production, low labor intensity.

The main working scopes

The equipment is mainly applied in cleaning apples, pears and carrots and the like fruits and vegetables. This product is designed in accordance with the hygienic requirements of the food industry. It is easy to operate, convenient to use and maintain, and can be connected into automated assembly lines.

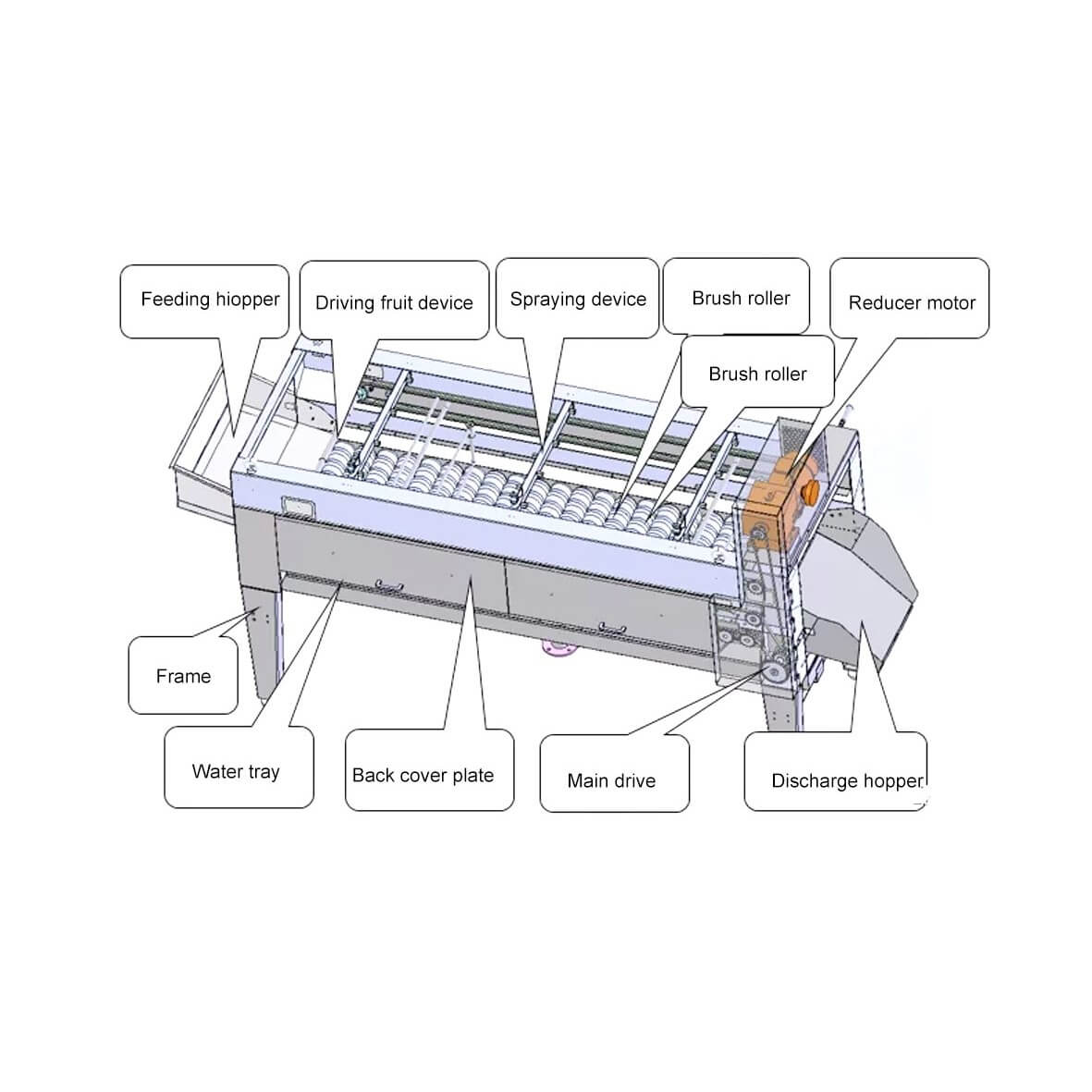

Main structure

The equipment is mainly composed of frame, main drive, passive drive, brush roller, reduction motor, fruit catching device, spray device, feed hopper, discharge hopper etc.

Fruit driving device(Entire machine features)

The surface of the brush roller is elliptical arc shape, which can effectively remove the residues, debris and pesticide residues on the fruit skins.

The upper part of the machine is equipped with a spray device, which can effectively wash and remove the agricultural residues, leaves and soil remaining on the surface of fruits and vegetables.The frame structure welded by stainless steel tubes and other profiles, with good overall rigidity, the whole machine in low vibration, and the transmission chain has a safety cover to ensure good safety protection performances.The equipment has a fruit catching device, effectively convey the remaining product materials to the discharge port, and then enter the next working section.

Working principles

The cleaned fruit go to the brush cleaning machine from the previous process, and come into the high-speed rotating brush roller. By means of the collisions between the fruit and the friction on fruit from the brush roller, remove the remaining agricultural residues, leaves and soil on the surface of the fruits and vegetables. The spray device on the top cleans the removed debris, several sets of brush rollers operate at the same time, and the auxiliary drive of the fruit drive device convey the product materials to the discharge port, and then go to the next process.

Technical parameter(refer to the raw fruit processing capacity)

|

Model |

Description |

External dimension (L×W×H)(mm) |

Suggested capacity

|

Suggested power(kw) |

|

|

capacity and power varies as to different fruits |

|||||

|

GMQXJ-2 |

The material used is sus304 stainless steel, speed is adjustable, with water spraying device |

3000*1000*1850

|

≤2(T/H) |

1.1 |

|

|

GMQXJ-5 |

3000*1250*1850 |

3~5(T/H) |

1.5 |

||

|

GMQXJ-10 |

3800*1500*2000 |

6~10(T/H) |

2.2 |

||

|

GMQXJ-15 |

4000*1650*2000 |

11~15(T/H) |

3 |

||

|

GMQXJ-20 |

4000*1900*2000 |

16~20(T/H) |

4 |

||

|

GMQXJ-40 |

4500*2200*2000 |

40(T/H) |

5.5 |

||

That's all what we had talked today about the Brush cleaning and peeling machine. please contact Beyond service engineer if you got any question.