Plate heat exchangers are a commonly used heat exchange device used to transfer heat in fluids. It consists of a series of parallel arranged metal plates, where one fluid flows through alternating channels and the other fluid flows through adjacent channels, transferring heat between the two.

The working principle of a plate heat exchanger is as follows:

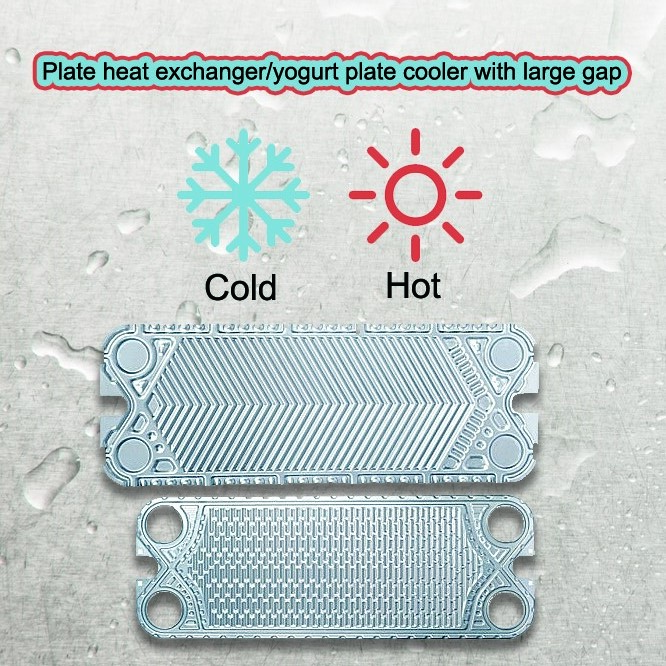

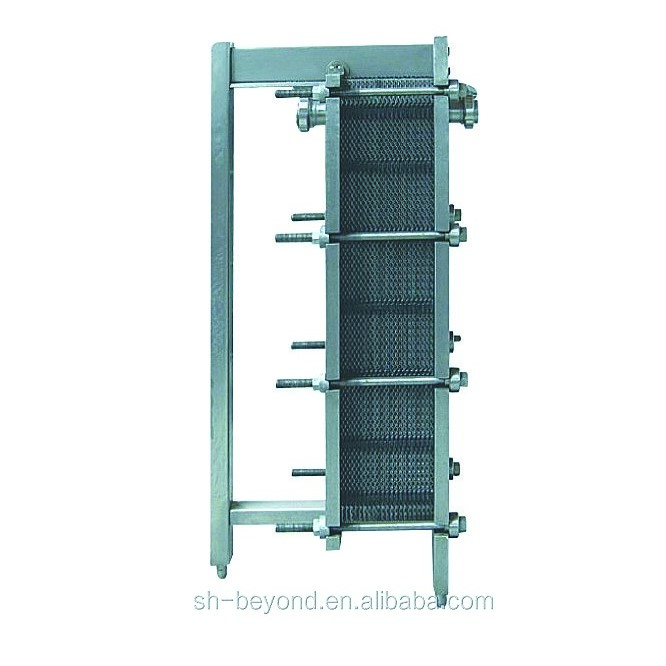

1. Sheet structure: Plate heat exchangers are composed of multiple thin plates, usually made of metal (such as stainless steel). These thin plates are connected together through sealing gaskets and fasteners, forming multiple channels.

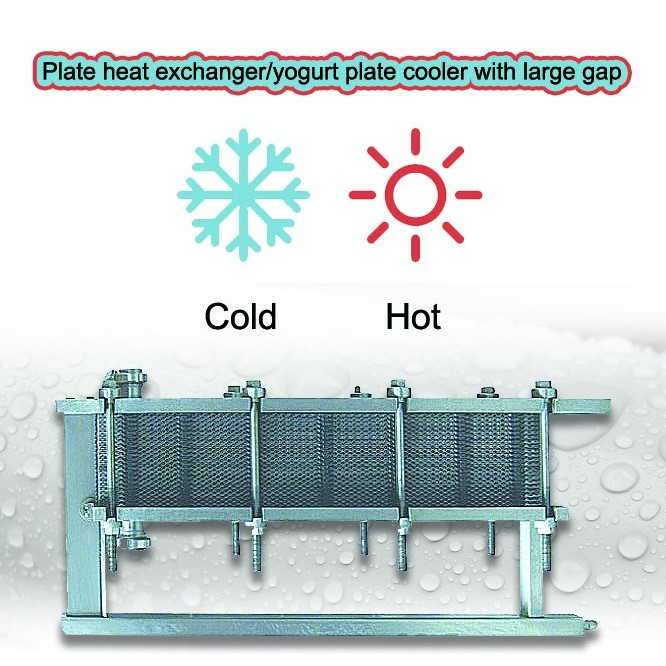

2. Fluid diversion: Two different fluids (which can be liquid or gas) flow through different channels of a plate heat exchanger. One type of fluid enters the alternate channel, called the heat source fluid, while the other type passes through adjacent channels, called the working fluid.

3. Heat transfer: When the heat source fluid and working fluid pass through the plate wall, heat is transferred from the higher temperature fluid to the lower temperature fluid, achieving heat exchange.

4. Main heat transfer methods: Plate heat exchangers mainly transfer heat through convection and heat conduction. Usually, the heat source fluid and the working fluid cross flow between adjacent channels, thereby increasing the heat conduction effect and improving the heat transfer efficiency.

5. Fluid separation: In order to ensure the isolation of two fluids and prevent mixing, plate heat exchangers usually have sealing measures that do not leak.

Advantages of plate heat exchangers:

1. Efficient heat transfer: Due to the design of the plate wall that can increase the surface area and the high flow velocity between fluids, the plate heat exchanger has excellent heat transfer efficiency.

2. Compact structure: The plate heat exchanger adopts a parallel arrangement of thin plates, which occupies relatively less space and is suitable for situations with limited space.

3. Low temperature sensitivity: Due to the good thermal conductivity of metal plates, plate heat exchangers respond quickly to temperature changes, enabling more accurate temperature control and adjustment.

4. Easy to maintain and clean: As the plate heat exchanger can be disassembled, cleaning and maintenance are relatively convenient.

Plate heat exchangers are widely used in the industrial field, especially in fields such as chemical engineering, food processing, pharmaceuticals, cooling systems, and heating systems. It has efficient heat exchange performance and can achieve the advantages of energy conservation and resource utilization.

Description Of The Product

Plate heat exchanger is a high effective heat exchanging equipment, can be used in such fields as chemicals, metallurgy, petroleum, power station, agriculture chemicals, paper making, pharmacy, air-conditioner, beer, beverage, and biological project. it is of advantages of compact structure, large heat exchanging area, small area taking, and easy disassembly, cleaning and maintain. The plate heat exchanger made in our company adopts stainless steel, hasp sealing robber cushion, so especially fit for food ,beverage and dairy product. Plate material: US304,SUS316l,Tai plate etc Rubber cushion material: NBR,NBR,EPDM,TP Single palte area: 0.05㎡,01㎡,0.16㎡,0.26㎡,0.6㎡

Technical parameter:

1·heat exchanging area of single plate:0.16 ㎡

2·heat exchanging area of single machine: 16 ㎡

3· outline dimensions: 1200*350*1320mm