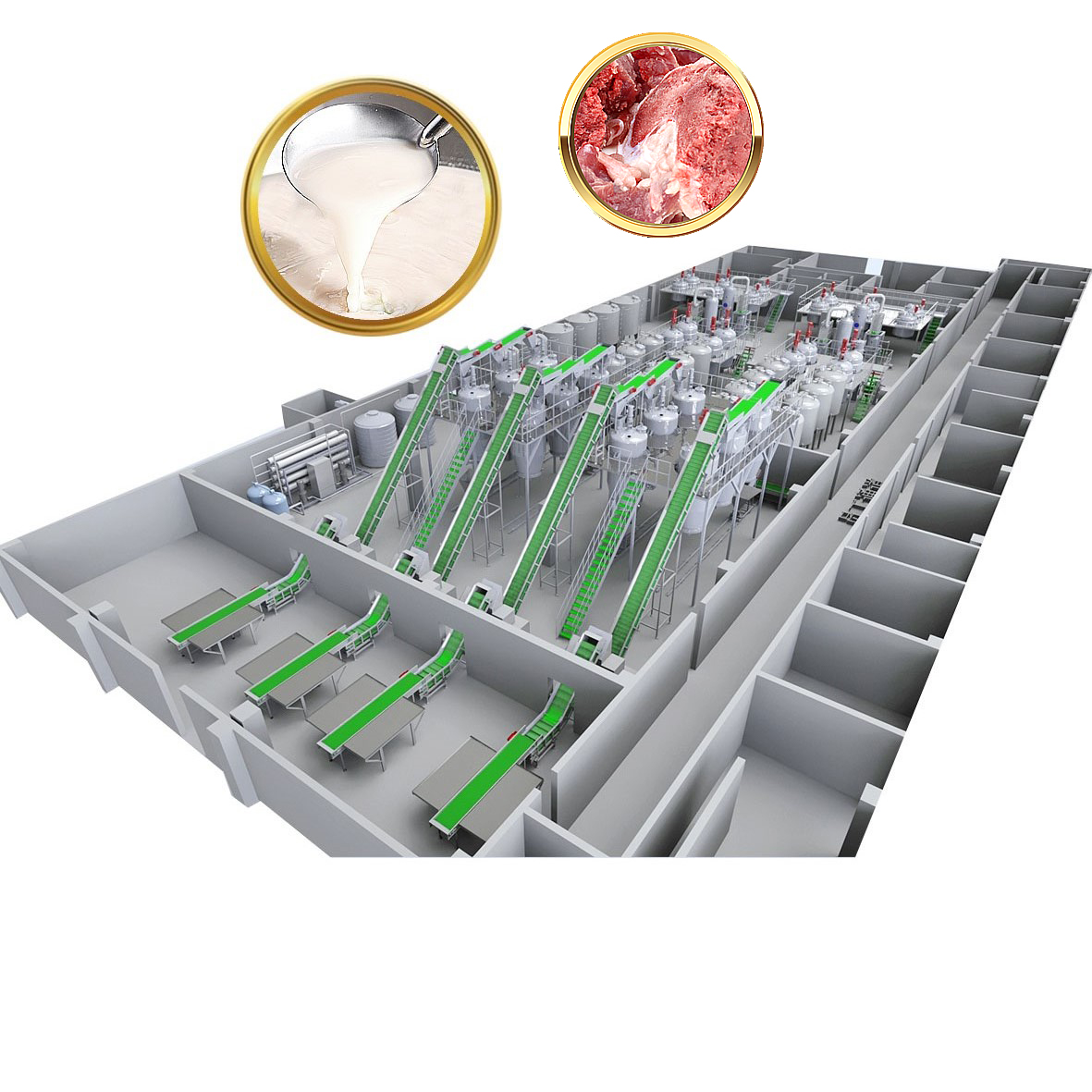

A pet wet grain processing production line is a system used to produce wet grain pet food or treats. This production line typically consists of several machines that work together to process and package the wet grain pet food.

The production line usually starts with a cleaning machine, which removes impurities and foreign materials from the grains. Then, the grains are cooked in a steam cooker to soften them and make them more digestible for pets.

After cooking, the grains are passed through a grinder or mill to break them down into smaller particles. This step helps in improving the texture of the pet food and also aids in digestion.

Next, the ground grains are mixed with other ingredients such as meats, vegetables, vitamins, and minerals. This mixing process is typically done in a mixer or blender, ensuring that all the ingredients are thoroughly combined.

Once the mixture is ready, it is shaped into desired forms using a shaping machine or extruder. This machine can create different shapes and sizes of pet food, such as pellets, chunks, or sticks.

After shaping, the pet food is typically dried using a drying oven or a dehydrator. This step removes moisture from the product, increasing its shelf life and preventing the growth of bacteria or mold.

Finally, the dried pet food is packaged using a packaging machine. The packaging can be in various forms, such as bags, pouches, or cans, depending on the requirements of the manufacturer.

Overall, a pet wet grain processing production line is designed to efficiently and hygienically produce high-quality wet grain pet food or treats. It incorporates various machines and processes to ensure the proper cleaning, cooking, grinding, mixing, shaping, drying, and packaging of the final product.

Raw materials ->Metal inspection ->Crushing ->Ground meat ->Ingredients grinding ->Emulsification ->Extrusion ->Cooking ->Cooling ->Cutting ->Packaging

Raw materials ->Gold inspection ->Crushing ->Ground meat ->Thawing ->Ingredients grinding ->Temporary storage ->Packaging

Key equipment for wet grain processing production line

Equipment description: The double screw belt mixer is an essential equipment for high viscosity and high solid content mixing, with high efficiency, easy operation, uniform mixing, and suitable for various process requirements.

Main features: A is made of food grade SUS304, which meets food hygiene requirements and can be CIP cleaned.

B has a reasonable design and flexible and easy operation. The mixing time can be set, and the interval time and mixing program greatly improve work efficiency.

The C-axis adopts a dual bearing structure, which improves the mixing efficiency and effect. Free control of forward and reverse rotation, automatic discharge, and multiple choices of blade forms.

D adopts reducer gear chain transmission/reducer direct connection transmission, ensuring smooth and reliable machine movement with low noise, suitable for various process requirements.

Application scope: Mainly used for mixing powders, semi-solids, meat, and fats, it is the preferred equipment for pet wet grain processing, intestinal products, and pill products

② Vacuum feeding machine

Overview: The vacuum feeding machine is composed of a vacuum pump, vacuum hopper, filter, vacuum valve, pulse back blowing device, pneumatic discharge valve, electric control device, etc; The negative pressure airflow generated by the electric vacuum pump drives the powder and particle materials to flow forward into the vacuum hopper, and the filter plays a role in separating the material from the air, discharging clean air into the atmosphere through the filter element.Main features: A provides a cleaner transportation method for powder transportation

B is suitable for use with dust-free feeding stations, improving the workshop environment, and providing possibilities for material dust-free workshops

C can be used in conjunction with the fan to achieve continuous cutting

D quick installation clamp connection, convenient for disassembly, cleaning, and compliance with hygiene requirements

Main function: Vacuum feeding machine is widely used in industries such as chemical, pharmaceutical, food, metallurgy, etc.

③ Cooking tunnel

Equipment description: The tunnel type cooking machine can achieve continuous material cooking and qualitative analysis. The processing time and cooking temperature of different cooking materials will have certain temperature differences, and the temperature and time can be adjusted. Cut and seal properly to avoid problems such as steam leakage and leakage. Design an insulation layer to provide insulation and heat preservation.Main features: Equipment A is designed with a curtain, and the inlet and outlet ends are extended to avoid steam leakage issues

B adopts stainless steel chain plate design for easy cleaning

C fully automatic control, temperature and time adjustable

D split end temperature, making the material more evenly heated