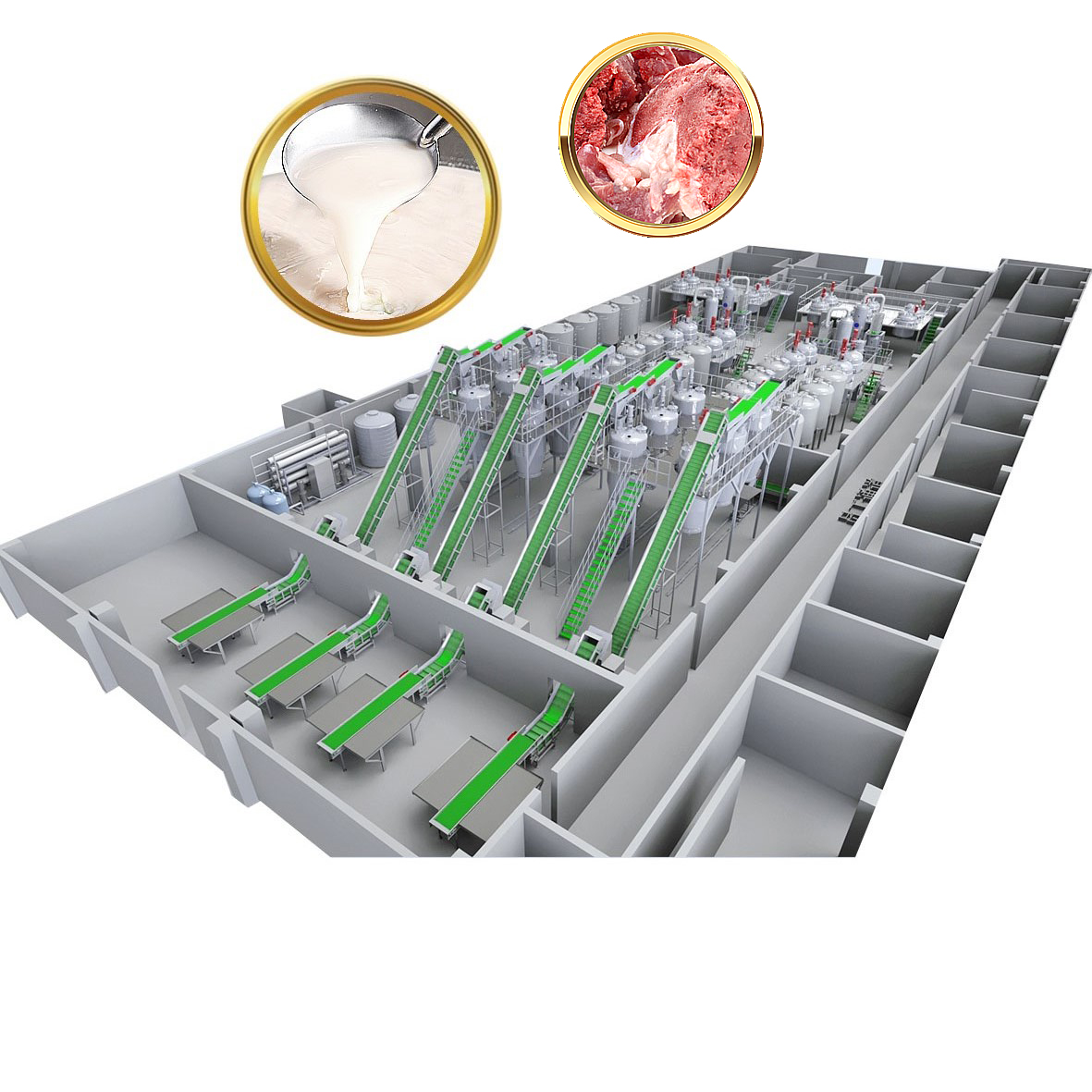

Some steps for setting up a fresh meat addition production line:

Design and layout: Determine the space needed for the production line, considering factors such as the volume of production, storage requirements, and workflow efficiency.

Equipment selection: Choose the appropriate equipment for each stage of the production line, including meat grinders, mixers, slicers, portioning machines, vacuum sealers, and packaging machines. Consider factors such as capacity, quality, and safety features.

Raw material handling: Establish a system for receiving, inspecting, and storing fresh meat. Ensure proper temperature control to maintain product freshness and quality.

Meat processing: Set up a series of processes for grinding, mixing, portioning, and slicing the meat. This may involve different machines or workstations, depending on the specific product requirements.

Seasoning and ingredient addition: If necessary, incorporate steps for adding seasonings, spices, or other ingredients to the meat mixture. This may involve mixing equipment or manual processes.

Packaging and labeling: Integrate a packaging system to ensure proper sealing and labeling of the final product. Consider using vacuum packaging or other suitable packaging methods to extend the shelf life of the fresh meat.

Quality control: Implement measures to monitor and maintain consistent quality throughout the production line. This may involve regular inspections, testing, and adherence to food safety regulations.

Cleaning and sanitation: Develop a thorough cleaning and sanitation protocol to ensure the hygiene and safety of the production line. Regularly clean and disinfect all equipment, tools, and surfaces.

Training and staffing: Provide comprehensive training to employees operating the production line. Ensure they understand the processes, safety protocols, and quality standards.

Continuous improvement: Regularly evaluate the performance of the production line and identify areas for improvement. Stay updated on industry trends and technological advancements to optimize efficiency and product quality.

Remember to comply with local regulations and standards regarding food production and safety when setting up and operating a fresh meat addition production line.

Key Equipment for Fresh Meat Addition Production Line

Equipment description: Double axis crusher, which is a medium to light load shear crusher. This product is equipped with a single motor reducer, which drives two sets of cutter shafts to operate simultaneously through a gear division box. The equipment is compact in size, but its core is very powerful, with alloy cutting materials, various protections, and an integral reduction bearing seat.

Main features: A dual shaft crusher has a large single machine capacity, which can meet the current increasing production capacity and large-scale production needs

Suitable for processing various raw materials such as chicken, chicken skeleton, chicken liver, fish, etc

C Crushing size is uniform

Application field: Biaxial crushing randomization is mainly used for crushing animal carcasses, large animal bones, and various -18 ℃ frozen plates.

Equipment description: The frozen meat grinder relies on screws to push the raw materials in the hopper to the pre cutting plate, and through the rotation and compression of the screws, the orifice plate and the cutter rotate relative to each other, thereby cutting the raw meat into granules.

Main features: Equipment A has good universality, wide applicability, and high production efficiency;

B has the function of frozen meat grinding, which is time-saving, labor-saving, fresh-keeping, and high-quality;

The C twisting process takes a short time and has a low temperature rise, which is beneficial for preservation and prolongs the shelf life;

Multiple combinations of orifice plates are more suitable for the requirements of different meat products.

Application field: Meat grinder is mainly used in a wide range of meat and cartilage processing equipment, which can crush raw meat for production, or for later grinding, or to chop and mix.

Design description: On the basis of colloidal grinding, the precision grinding machine optimizes the grinding head mechanism to ensure smoother material entry and exit, better wear resistance, and larger processing capacity for models with equal power.

Main features: A optimizes the grinding head mechanism, allowing the material to undergo short grinding and grinding from large to small gaps. Equal power models have greater processing capacity

B is made of SUS304 material except for the grinding head, which is pollution-free and easy to clean

Application field: Used for rough grinding in pet food processing, the actual function is to solve the problem of conveying frozen plates. Rough grinding refers to the further crushing of materials, while also providing a certain temperature rise for the materials, which is conducive to transportation.

Equipment description: Bone paste mill is mainly used in pet food, essence and spice, bone soup, seasoning and other industries; It adopts a tooth shaped grinding head with higher hardness, and the material is emulsified and crushed through the interaction of grinding and extrusion in the crushing chamber, which is processed into a delicate and evenly organized product.

Main features: A dedicated grinding head with high strength, suitable for various raw materials such as pig bone, cow bone, chicken bone, etc

B is made of SUS304 material except for the grinding head, which is pollution-free and easy to clean

Application field: Bone paste mill is mainly used in essence, spice, pet food and other industries. It can crush and grind bone and meat materials to a certain degree of fineness to meet production requirements.

Equipment description: The emulsifying machine has better emulsifying and crushing effects than the bone paste grinding machine, and the produced material tissue is more delicate. It has a certain degree of crushing and refining effect on fascia, fish bones, and other materials that are difficult to remove in bone and meat processing, making it a better grinding equipment at present.

Main features: After emulsification, the material of A is more delicate, with a certain emulsification effect, and the product has a more stable phase.

B meat products have a high protein precipitation rate, thereby improving product yield.

When the C emulsification machine is working, the materials pass through at once, so the temperature rise of the product is small and the tissue damage is small, which improves the quality of the product.

The D machine has a compact structure and reliable operation. The body, main components, and transmission components are processed and manufactured using stainless steel and high-quality steel, meeting food hygiene requirements.

The E emulsification head assembly has high precision, which can effectively control and improve the emulsification effect. The installation of the knife set has strict operating instructions.

Application field: Crushing, refining, shearing, and emulsifying bone and meat materials to achieve the required particle size for production, reducing the impact of fascia, fish bones, and other factors on the later stage.