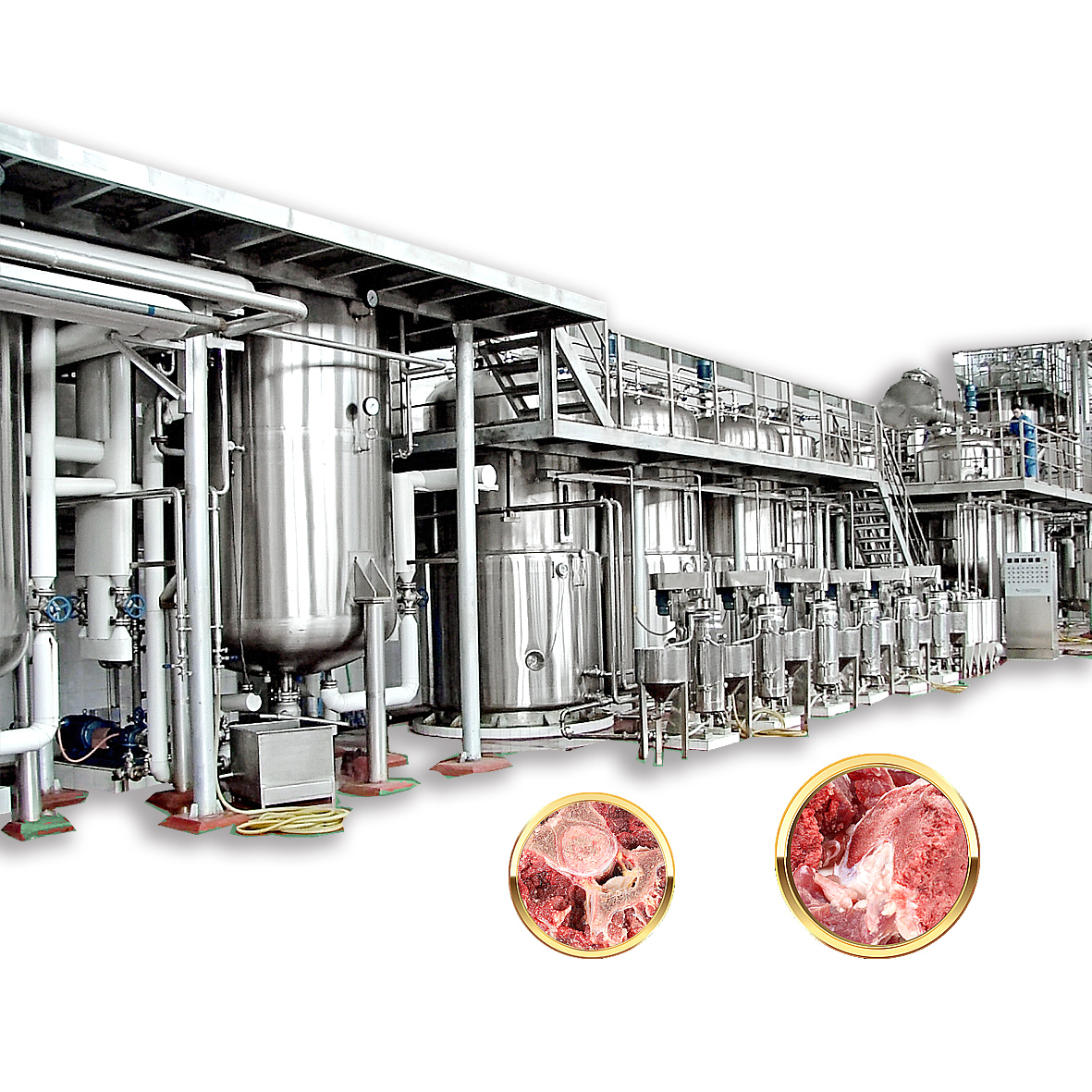

A bones soup processing production line is a system that is designed to process and produce soup products using bones as the main ingredient. This line typically consists of several machines and equipment that work together to complete various stages of the production process.

Bones Cleaning: The first step in the process is cleaning the bones to remove any dirt or debris. This can be done using a bone washing machine that uses water and brushes to scrub the bones clean.

Bones Sorting: After cleaning, the bones are sorted based on their size and quality. This can be done manually or with the help of a sorting machine that uses sensors to detect and separate bones based on their characteristics.

Bones Crushing: Next, the bones are crushed or ground into smaller pieces. This can be done using a bone crusher or grinder that reduces the bones into a more manageable size.

Bones Cooking: The crushed bones are then cooked to extract the flavors and nutrients. This can be done in a large cooking vessel or a specialized bone soup cooker that ensures proper cooking temperature and time.

Soup Extraction: Once the bones have been cooked, the soup is extracted from the mixture. This can be done using a filtration system that separates the liquid part from the solid bones and other impurities.

Soup Filtration: The extracted soup is then passed through a filtration system to remove any remaining particles or impurities. This can be done using a fine mesh filter or a centrifuge that separates the soup from any solid materials.

Soup Pasteurization: After filtration, the soup is pasteurized to eliminate any harmful bacteria or pathogens. This can be done by heating the soup to a specific temperature for a certain period of time.

Packaging: Finally, the processed soup is packaged into containers such as cans, bottles, or pouches. This can be done using an automated packaging machine that fills and seals the containers with the soup.

Overall, a bones soup processing production line allows for efficient and standardized production of bone soup products. It ensures that the bones are properly cleaned, processed, and packaged to meet quality and safety standards.

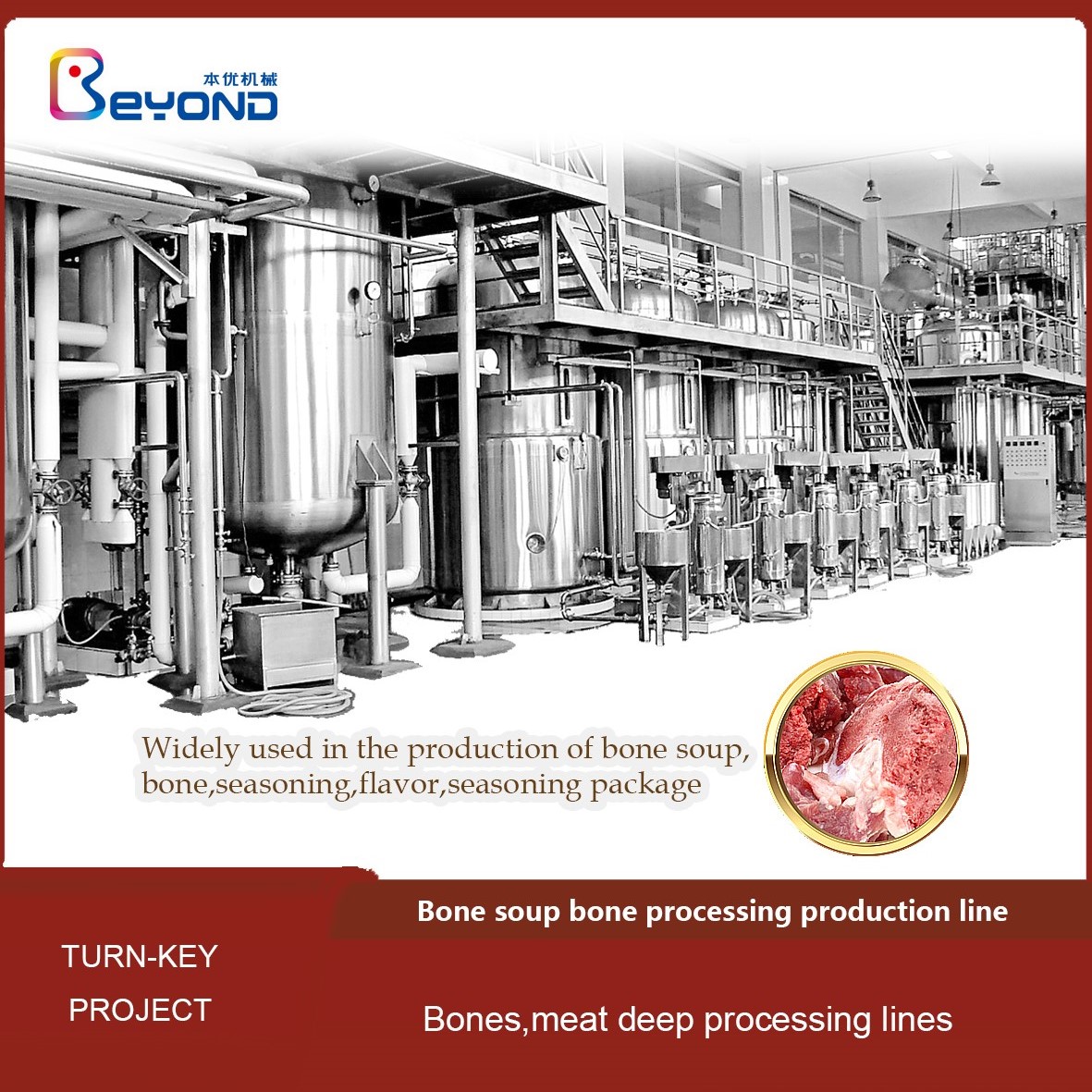

• Main composition

Raw material bone crushing and lifting system,Extraction system,condensate recovery system,Soup liquid separation system,concentration system,

Blending and sterilization system,Mailard reaction system,Finished product temporary storage system,canned system,Bone residue treatment system,automatic control system.

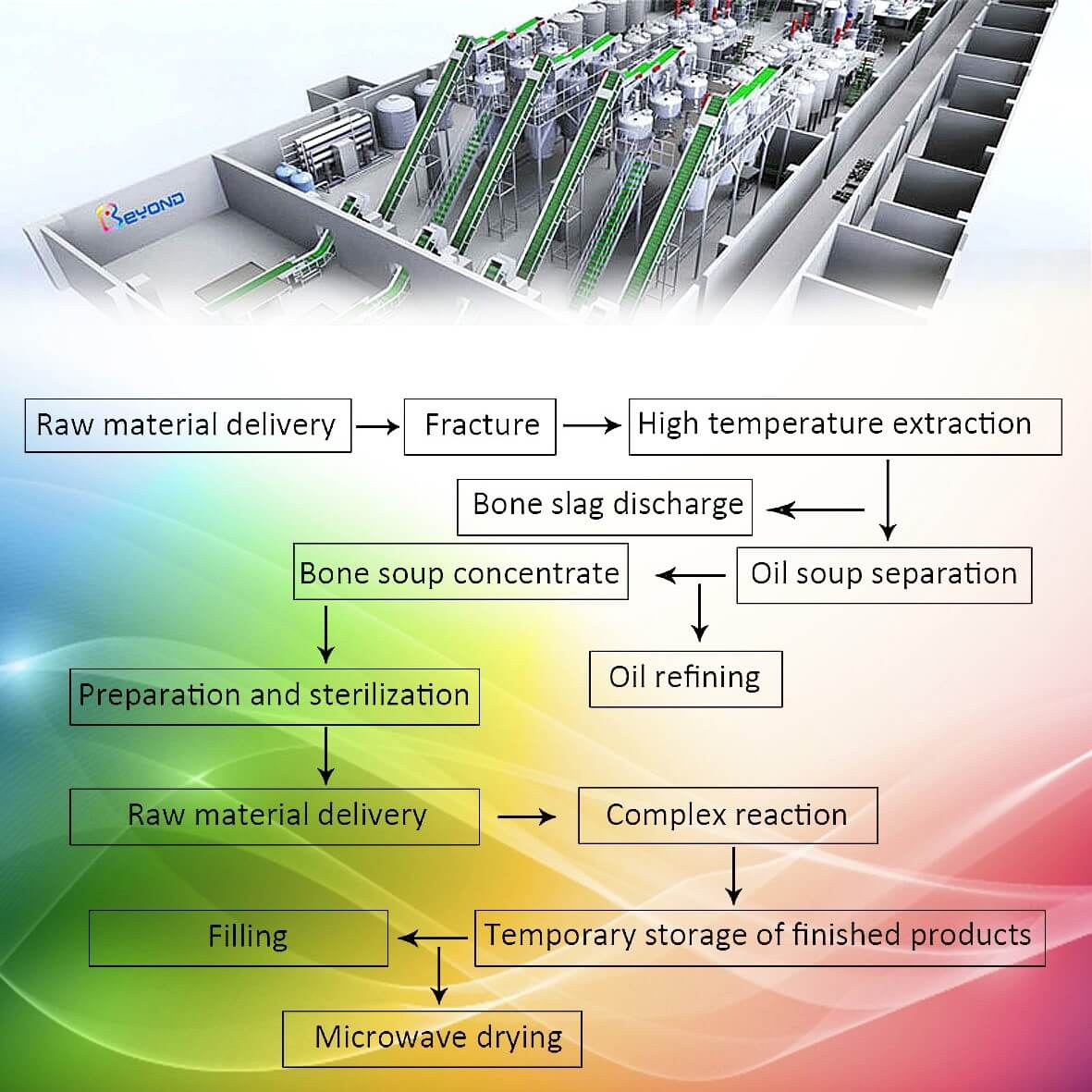

• Proccedure Flow

Raw animal bones/meat→Grinding→Pre-processing→ Extracting→ Separating →

Concentrating→Blending→Drying(Filling/Packing)→Finished Product

Bone Processing Pretreatment Unit

The system is mainly to crush on bones or frozen blocks, the broken product materials feed into the hanging cage through the scraper elevator. The cage is put into the extraction tank by crane for high temperature and high pressure extraction.

Bone Soup Extraction Unit

The system is designed as extraction tank with large open lid on the top, and the bone is put into a hanging basket for extraction.

The extraction method has the characteristics of a wide range of applicable materials and high operational safety. The crane puts the hanging basket into the extraction tank and then adds the hot water recovered by the heat energy for heating treatment.

The extraction tank designed by BEYOND has a two-stage hollow jacket + bottom steam direct injection pipe heating, and the steam direct injection pipe is used to go deep into the basket for direct heating, which avoids the central part of the material from not being heated and lead to the extraction effect is poor.

The whole extraction process is fully automatic temperature and pressure control, the temperature rises softly and gently, pressure with mechanical and automatic non-condensing gas emissions.

The pressure is strictly monitored during the extraction process, and the program is designed with the interlocking control over the pressure inside the tank and the switch lid. The top lid cannot be opened when there is pressure in the tank, so as to prevent safety accidents caused by workers' misoperation.

Bone soup is discharged with pressure, discharge pipeline is designed with gas-liquid separator, which not only saves the energy of the transfer pump, but also has the advantages of fast soup discharge, high yield etc..

Bone Residue Treatment Unit

The bone slag after extraction was lifted out by a crane and discharged from the bone slag discharge bin. At the same time, the hanging basket goes to washing and reused.

Stationary Separation Unit

The bone soup discharged from the extraction tank goes to the static separation tank, and the bone oil enters the scum oil tank. According to different production needs, a small amount of salt can be added to the standing tank for salting out. There are two standing tanks with or without stirring.

The static separation tank is designed with a side wall flat sight glass, which is convenient to observe the product materials state and stratification condition in the tank as well as discharge by manual operation.

Bone Oil Refining Unit

The system washes and precipitates the separated bone oil in the scum oil tank, and removes the protein etc. The final product oil comes into the two oil tanks for sale.

Bone Soup Concentration Unit

The system adopts double-effect forced circulation evaporator and heat pump technology at the same time, has the characteristics of high efficiency and energy saving.The uniquely designed separator ensures no foaming and no product materials leakage during the concentration process, and can realize continuous feeding and discharging.

Bone Soup&Bone Ossein Preparation Line

This unit is mainly composed of blending tank, emulsifying pump, high pressure homogenizer, rotor pump and so on. The concentrated product materials are based on different recipes to add supplementary materials for reconstitution or Maillard reaction, so as to prepare bone soup with different flavors.The compound materials are homogenized and emulsified by the emulsification pump, high-pressure homogenizer, etc., so that the taste and aroma of the product reach the best state.

Main machine list

| FRESH RAW MATERIAL SYSTEM | |||

| Grinder | 1 | ||

| Screw pump | 10T/H | outlet pressure 0.6MPA, frequency control motor, material SUS304, inlet and outlet size DN65 | 3 |

| Fresh raw material storage tank | 10m³ | SUS304 stainless steel, three layer dimple jacket ,Top center frame stirring, airtight manhole, digital display thermometer, CIP cleaning ball, cylinder legs, glass tube liquid level indicator, sample valve, Capacitor type high, low level gauge interface | 2 |

| Weighing module unit | 15000KG | Siemens brand, one unit consist of 3 pcs Shear beam type weighing module, with display instrument, bracket, signal cable, junction box | 2 |

| Centrifugal pump | 20T/H | SUS304 stainless steel, 24 meters lift, mechanical seal | 2 |

| Temperature control system | Germany Burket pneumatic Angle seat valve, JUMO temperature sensor | 2 | |

| LIQUID RAW MATERIAL DOSING SYSTEM | |||

| Liquid Premix tank | 0.2m³ | SUS304 stainless steel, single layer, Vertical cylindrical tank, airtight manhole, breather cap, digital readout thermometer, Four cylindrical legs | 1 |

| Capacitor level meter | G1/2" | PNP,threaded connection | 2 |

| Liquid Buffer tank | 0.2m³ | SUS304 stainless steel, single layer, Vertical cylindrical tank, airtight manhole, breather cap, digital readout thermometer, Four cylindrical legs | 3 |

| Capacitor level meter | G1/2" | PNP,threaded connection | 6 |

| Scale hopper tank | 0.05m³ | SUS304 stainless steel, single layer, Vertical cylindrical tank, airtight manhole, breather valve, digital readout thermometer, Two legs weighing module interface. | 6 |

| Weighing module unit | 100kg | Mettler Toledo & Siemens brand, one unit consist of 1 pcs single point Weighing module, with display instrument, bracket, signal cable, junction box | 6 |

| Centrifugal pump | 10T/H | SUS304 stainless steel, 24 meters lift, mechanical seal | 4 |

| Centrifugal pump | 3T/H | SUS304 stainless steel, 24 meters lift, mechanical seal | 3 |

| measuring support | SUS304, Measuring stacking support, stainless steel square pipe 100*50 mm, size: 5000*1200*2500(L*W*H) | 1 | |

| REACTION SYSTEM | |||

|

Reaction tank (Pressure tank) |

10m³ | Inner layer is SUS316L, other SUS304, three layer jacketed tank, up and down elliptical head cover, heating hollow jacketed ,Jacket is divided into upper and lower two layers, can do half a tank of materials, tank pressure - 0.1-0.3 mpa, jacketed acuities were 0.4 mpa, external thermal insulation, top center scraping wall mixing (speed 21 to 63 r/min, frequency control of motor speed, mechanical seal),Top eccentric and decentralized high-speed mixing (speed 960RPM, frequency conversion speed regulation, mechanical seal), pressure quick-opening manhole, manhole center with glass sight, relief valve, needle gauge, electric contact pressure gauges, sight glasses lamp, at the top of the CIP cleaning ball, one set at the bottom of the temperature sensor and digital display thermometer 1, tank wall mirror polishing. Three cylindrical legs, high and low capacitance liquid level gauges. | 2 |

| Capacitor level meter | G1/2" | PNP,threaded connection | 4 |

| Weighing module unit | 15000KG | Siemens brand, one unit consist of 3 pcs Shear beam type weighing module, with display instrument, bracket, signal cable, junction box | 2 |

| Temperature Sensor | PT1000 | SUS304, 4-20mA signal output, range from 0-200℃ | 2 |

| Temperature control system | UK Spirax sarco reducing valve, trap system, Chinese famous brand stop valve, steam instrument | 2 | |

| Rotor pump | 10T/H | outlet pressure 0.6MPA, frequency control motor, material SUS304, inlet and outlet size DN50 | 4 |

| Circular vibrating screen | 10T/H | SUS304 stainless steel, solid-liquid separation (double layer), screen surface diameter 1500mm, 80 mesh aperture | 2 |

| Buffer tank | 1m³ | SUS304 stainless steel, single layer airtight manhole, digital display thermometer, CIP cleaning ball, adjustable legs, glass tube indicator, sample valve, Capacitor type high, low level gauge interface | 2 |

| Capacitor level meter | G1/2" | PNP,threaded connection | 4 |

| Allocate Plate | Ø51 | SUS304 stainless steel, five holes, with five manual butterfly value, with water receiver pan | 2 |

| STORAGE TANK SYSTEM | |||

| Temporary storage tank | V=20m³ | SUS304 stainless steel, single layer airtight manhole, with decentration paddle mixer, 32 RPM,digital display thermometer, CIP cleaning ball, three cylinder legs, glass tube indicator, sample valve, Capacitor type high, low level gauge interface, Top guardrail, manhole ladder with guardrail | 2 |

| Weighing module unit | 15000KG | Siemens brand, one unit consist of 3 pcs Shear beam type weighing module, with display instrument, bracket, signal cable, junction box | 2 |

| Capacitor level meter | GO/2" | PNP, threaded connection | 4 |

| Rotor pump | 10T/H | outlet pressure 0.6MPA, frequency control motor, material SUS304, inlet and outlet size DN50 | 2 |

| Electromagnetic flowmeter | 10T/h | 4-20mA signal output, with pulse counting | 2 |

| Allocate Plate | Ø51 | SUS304 stainless steel, five holes, with five manual butterfly value, with water receiver pan | 2 |