• Bone soup brief introduction

Peptone in bone soup comes from collagen fibers in animal food. When collagen in animals is heated, these entangled proteins will be dissolved and rearranged. As the heat goes on, the dissolved protein will slowly dissolve into the soup. When the bone soup is cooled, these proteins are reconnected to form what we call animal gelatin.

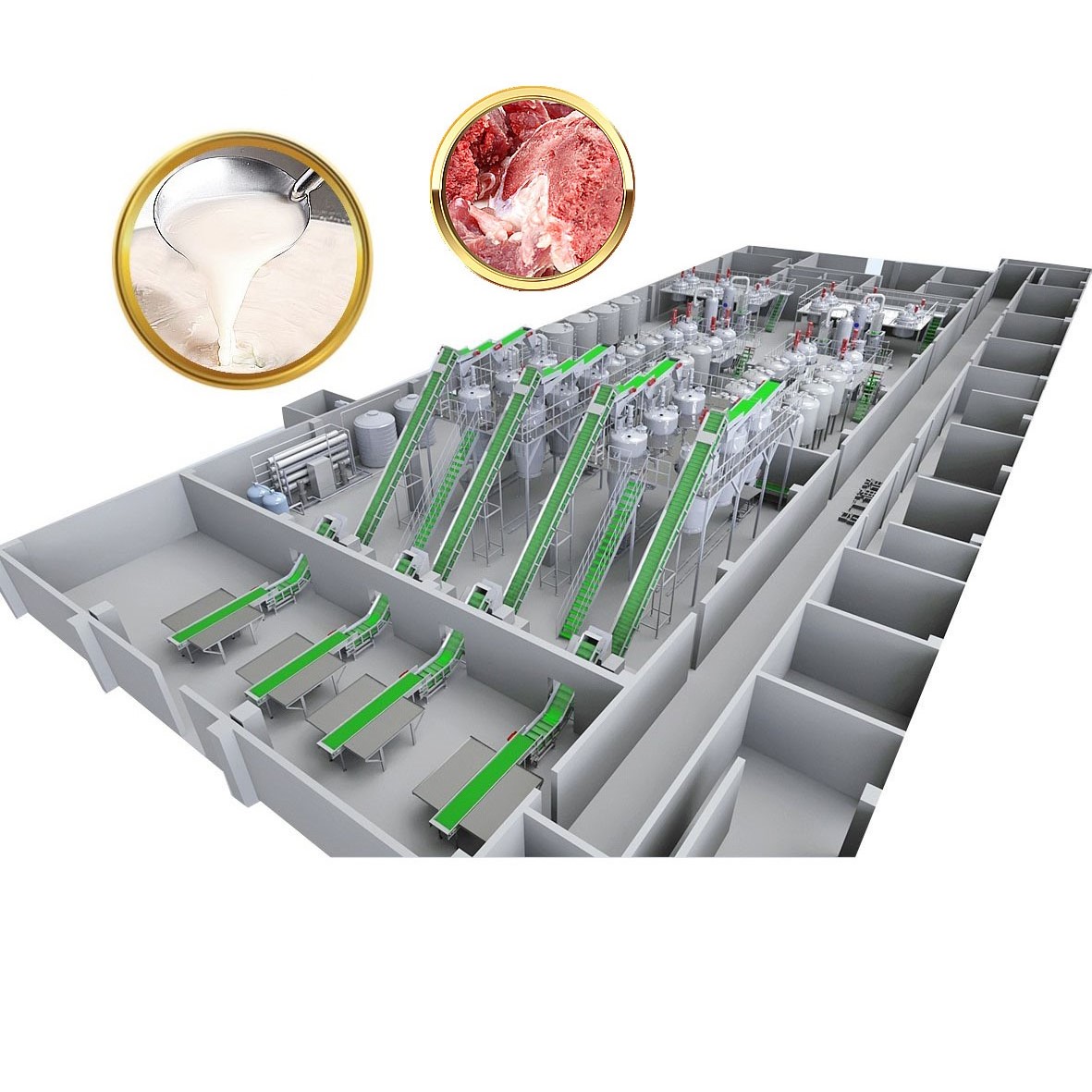

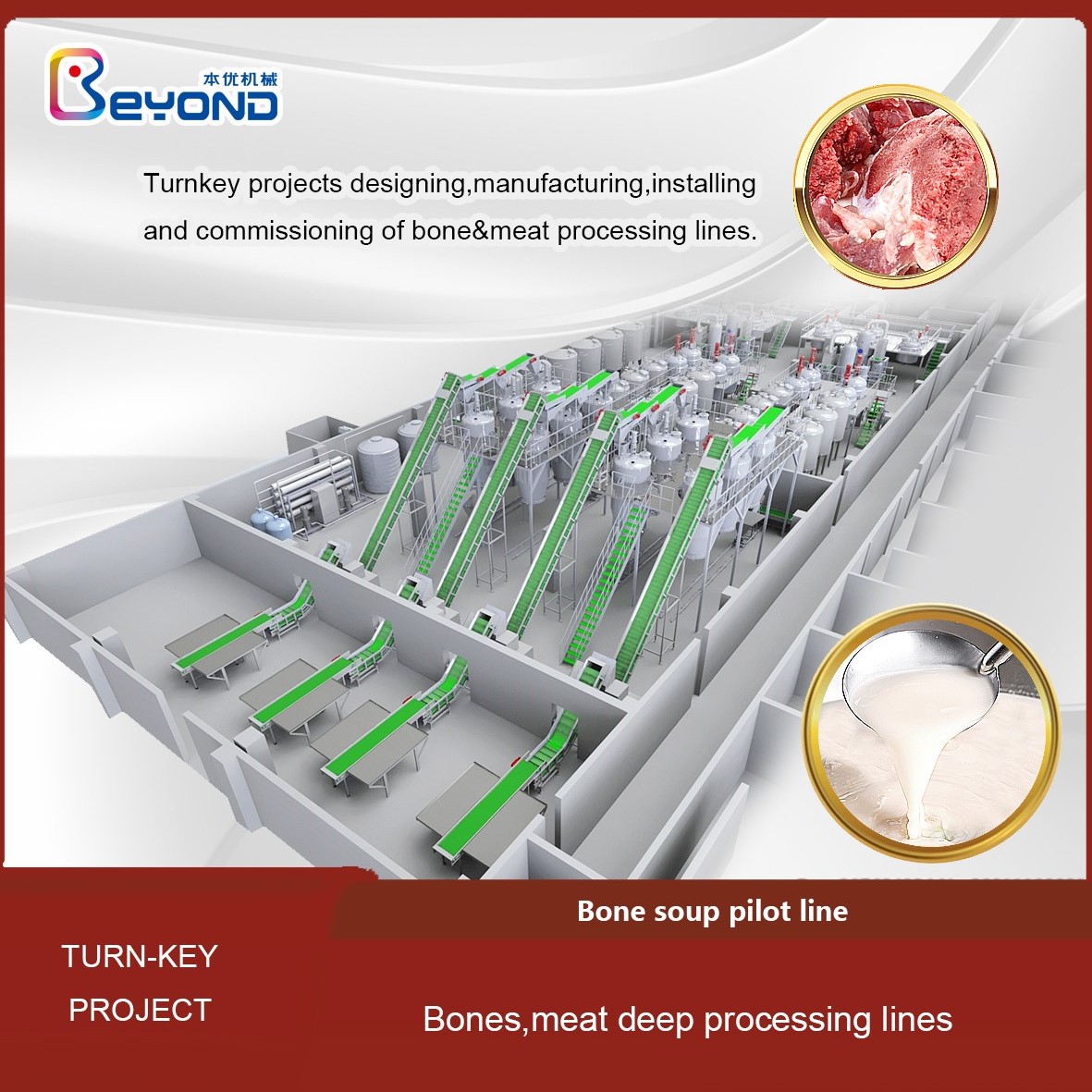

• Introduction of bone soup production line

Specializing in providing a full set of equipment for paste soup and condiment production line, focusing on factory building service. According to the needs, we can make the production line of soup, bone soup, seasoning, soup, hot pot soup, clear soup, white soup, hot pot, dipping, sauce, sauce, essence and other finished products.

• Main composition

Raw material bone crushing and lifting system,Extraction system,condensate recovery system,Soup liquid separation system,concentration system,Blending and sterilization system,Mailard reaction system,Finished product temporary storage system,canned system,Bone residue treatment system,automatic control system.

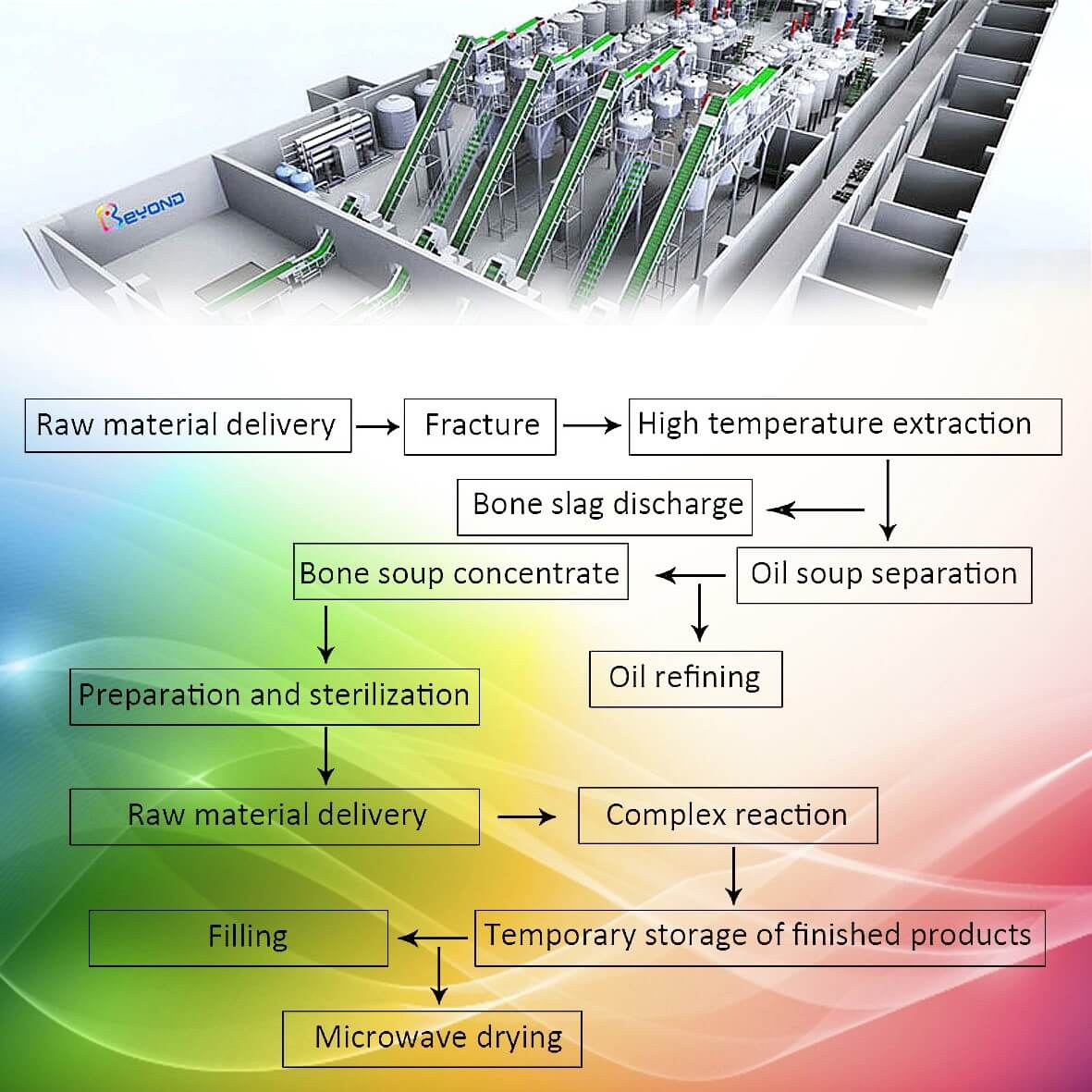

• Proccedure Flow

Raw animal bones/meat→Grinding→Pre-processing→ Extracting→ Separating →

Concentrating→Blending→Drying(Filling/Packing)→Finished Product

• Bone soup nutrition

Bone soup is rich in animal gelatin. Animal gelatin can help repair intestinal leakage and is a good source of glycine and proline. In lean meat, the content of glycine and purine is very small.Glycine can promote digestion, help the body excrete heavy metals and accelerate wound repair; Proline can combine with vitamin C to resist atherosclerosis.

Moreover, bone soup is also rich in glucosamine, chondroitin and other mucopolysaccharides. These substances can maintain the health of our digestive system and reduce inflammation.In addition, bone marrow is also rich in vitamin A, vitamin K2, zinc, selenium, manganese and other nutrients. These substances are very helpful in maintaining a healthy bone state.

Material pretreatment system

According to the characteristics of high hardness, large shape difference and high crushing difficulty of bovine bone, after repeated research and development, a complete set of pretreatment equipment for intelligent feeding, inductive bone breaking and visual cleaning is designed, which realizes the full-automatic unmanned operation from feeding, bone breaking and cleaning.

Intelligent extraction system

The system includes hardware systems such as automatic material metering, laser positioning feeding, whole process digital temperature control, multiple misoperation protection, full-automatic discharging, as well as software systems such as menu extraction, whole process monitoring and automatic cost accounting. It completely solves the problems of low efficiency, poor safety, low integration and automation of hard bone extraction. Compared with the traditional extraction equipment, the labor efficiency and extraction rate are increased by 26% and 22% respectively, and the energy consumption is saved by more than 19%.

Automatic discharge system

The system is logically coupled with the intelligent extraction system. The AGV slag truck adopts photoelectric positioning, automatic operation and automatic transportation to realize unmanned operation in the humid and hot environment.

Oil separation enzymatic hydrolysis system

For the multiple emulsification system of oil water protein, a special extraction separation tank is designed. Combined with the large taper structure at the bottom and the dynamic mixing system, it can realize the rapid settlement of impurities by the precipitation auxiliary agent and reduce the loss of effective materials. Combined with the actual operation, it is equipped with visual liquid level stratification mirror and multi-stage discharge port. The water oil phase mixture in the upper layer can be separated quickly and effectively by ultra-high speed centrifuge.

The targeted site enzymolysis system adopts accurate temperature control and multi-layer mixing and stirring technology, optimizes the enzymolysis time, temperature, pH and other process parameters, and improves the enzymolysis efficiency and mixing uniformity by 1 ~ 3 times.

Essential oil refining system

Through preliminary crude extraction and pre separation, high nutritional value bone oil with high purity, bright color and rich in linoleic acid and unsaturated fatty acid is prepared after deproteinization, alkali refining, hydration degumming, drying and high-speed centrifugation in a special oil treatment tank.

Purification and decolorization system

With the aid of high-quality nutshell granular activated carbon and refined diatomite, the impurities and the unique fishy smell of the material are fully adsorbed through circulating filtration to obtain high-quality collagen peptides. The anion anion adsorption resin device with special structure for collagen peptide was designed to effectively remove the inorganic ash contained in the solution.

Membrane separation and concentration system

The system adopts American Dow Chemical ultrafiltration and nanofiltration membrane materials, fully imported power unit and Siemens man-machine interface control system to realize directional functional peptide production through the interception and separation of collagen peptides with different molecular weights. The high-purity collagen peptide is obtained and the water is removed at the same time, so as to realize the pre concentration of the material, and the material concentration can reach more than brix25 °.

Sterilization falling film concentration system

A special sterilizer and a double effect falling film concentrator for high protein and high viscosity liquids were designed. The whole system has reasonable and beautiful design, compact structure and small floor area; High efficiency and energy saving (reuse of secondary steam / steam coefficient up to 0.7), high concentration ratio (Baume degree can reach more than 45 °) , fully automatic operation. It is characterized by rapid flow and evaporation of material liquid with high viscosity. In the heat exchanger with high heat transfer coefficient, the heat is fully utilized, and the material liquid is heated gently to prevent coking; the specially designed gas-liquid separator strengthens the separation effect after the steam water mixture enters, so that the overall equipment has great operation flexibility; the operation realizes continuous feeding and discharging of materials and materials The liquid level and the required concentration can be monitored on-line, digitally controlled and fully automated.

Pressure spray drying system

The spray drying of the wide tower is three stage drying. Steam heat exchange and electric auxiliary heating, high pressure nozzle atomization, hot air mixing flow, top wind tower, built-in fixed fluidized bed, two stage cyclone and water film dedusting are carried out safely, reliably and continuously.

Automatic CIP system

Siemens PLC control system and color display touch screen are adopted. The three loops operate at the same time to reduce the cleaning time. It can realize the automatic control of tank temperature and discharge temperature, automatic control and compensation of acid-base concentration, automatic alarm of equipment fault to be cleaned, automatic control of tank liquid level and automatic switching of CIP process.

Main machine list

|

FRESH RAW MATERIAL SYSTEM

|

|

|

|

||

|

Grinder

|

|

|

1

|

||

|

Screw pump

|

10T/H

|

outlet pressure 0.6MPA, frequency control motor, material SUS304, inlet and outlet size DN65

|

3

|

||

|

Fresh raw material storage tank

|

10m³

|

SUS304 stainless steel, three layer dimple jacket ,Top center frame stirring, airtight manhole, digital display thermometer, CIP cleaning ball, cylinder legs, glass tube liquid level indicator, sample valve, Capacitor type high, low level gauge interface

|

2

|

||

|

Weighing module unit

|

15000KG

|

Siemens brand, one unit consist of 3 pcs Shear beam type weighing module, with display instrument, bracket, signal cable, junction box

|

2

|

||

|

Centrifugal pump

|

20T/H

|

SUS304 stainless steel, 24 meters lift, mechanical seal

|

2

|

||

|

Temperature control system

|

|

Germany Burket pneumatic Angle seat valve, JUMO temperature sensor

|

2

|

||

|

LIQUID RAW MATERIAL DOSING SYSTEM

|

|

|

|

||

|

Liquid Premix tank

|

0.2m³

|

SUS304 stainless steel, single layer, Vertical cylindrical tank, airtight manhole, breather cap, digital readout thermometer, Four cylindrical legs

|

1

|

||

|

Capacitor level meter

|

G1/2"

|

PNP,threaded connection

|

2

|

||

|

Liquid Buffer tank

|

0.2m³

|

SUS304 stainless steel, single layer, Vertical cylindrical tank, airtight manhole, breather cap, digital readout thermometer, Four cylindrical legs

|

3

|

||

|

Capacitor level meter

|

G1/2"

|

PNP,threaded connection

|

6

|

||

|

Scale hopper tank

|

0.05m³

|

SUS304 stainless steel, single layer, Vertical cylindrical tank, airtight manhole, breather valve, digital readout thermometer, Two legs weighing module interface.

|

6

|

||

|

Weighing module unit

|

100kg

|

Mettler Toledo & Siemens brand, one unit consist of 1 pcs single point Weighing module, with display instrument, bracket, signal cable, junction box

|

6

|

||

|

Centrifugal pump

|

10T/H

|

SUS304 stainless steel, 24 meters lift, mechanical seal

|

4

|

||

|

Centrifugal pump

|

3T/H

|

SUS304 stainless steel, 24 meters lift, mechanical seal

|

3

|

||

|

measuring support

|

|

SUS304, Measuring stacking support, stainless steel square pipe 100*50 mm, size: 5000*1200*2500(L*W*H)

|

1

|

||

|

REACTION SYSTEM

|

|

|

|

||

|

10m³

|

Inner layer is SUS316L, other SUS304, three layer jacketed tank, up and down elliptical head cover, heating hollow jacketed ,Jacket is divided into upper and lower two layers, can do half a tank of materials, tank pressure - 0.1-0.3 mpa, jacketed acuities were 0.4 mpa, external thermal insulation, top center scraping wall mixing (speed 21 to 63 r/min, frequency control of motor speed, mechanical seal),Top eccentric and decentralized high-speed mixing (speed 960RPM, frequency conversion speed regulation, mechanical seal), pressure quick-opening manhole, manhole center with glass sight, relief valve, needle gauge, electric contact pressure gauges, sight glasses lamp, at the top of the CIP cleaning ball, one set at the bottom of the temperature sensor and digital display thermometer 1, tank wall mirror polishing. Three cylindrical legs, high and low capacitance liquid level gauges.

|

2

|

||

|

Capacitor level meter

|

G1/2"

|

PNP,threaded connection

|

4

|

||

|

Weighing module unit

|

15000KG

|

Siemens brand, one unit consist of 3 pcs Shear beam type weighing module, with display instrument, bracket, signal cable, junction box

|

2

|

||

|

Temperature Sensor

|

PT1000

|

SUS304, 4-20mA signal output, range from 0-200℃

|

2

|

||

|

Temperature control system

|

|

UK Spirax sarco reducing valve, trap system, Chinese famous brand stop valve, steam instrument

|

2

|

||

|

Rotor pump

|

10T/H

|

outlet pressure 0.6MPA, frequency control motor, material SUS304, inlet and outlet size DN50

|

4

|

||

|

Circular vibrating screen

|

10T/H

|

SUS304 stainless steel, solid-liquid separation (double layer), screen surface diameter 1500mm, 80 mesh aperture

|

2

|

||

|

Buffer tank

|

1m³

|

SUS304 stainless steel, single layer airtight manhole, digital display thermometer, CIP cleaning ball, adjustable legs, glass tube indicator, sample valve, Capacitor type high, low level gauge interface

|

2

|

||

|

Capacitor level meter

|

G1/2"

|

PNP,threaded connection

|

4

|

||

|

Allocate Plate

|

Ø51

|

SUS304 stainless steel, five holes, with five manual butterfly value, with water receiver pan

|

2

|

||

|

|

|

STORAGE TANK SYSTEM

|

|

||

|

Temporary storage tank

|

V=20m³

|

SUS304 stainless steel, single layer airtight manhole, with decentration paddle mixer, 32 RPM,digital display thermometer, CIP cleaning ball, three cylinder legs, glass tube indicator, sample valve, Capacitor type high, low level gauge interface, Top guardrail, manhole ladder with guardrail

|

2

|

||

|

Weighing module unit

|

15000KG

|

Siemens brand, one unit consist of 3 pcs Shear beam type weighing module, with display instrument, bracket, signal cable, junction box

|

2

|

||

|

Capacitor level meter

|

GO/2"

|

PNP, threaded connection

|

4

|

||

|

Rotor pump

|

10T/H

|

outlet pressure 0.6MPA, frequency control motor, material SUS304, inlet and outlet size DN50

|

2

|

||

|

Electromagnetic flowmeter

|

10T/h

|

4-20mA signal output, with pulse counting

|

2

|

||

|

Allocate Plate

|

Ø51

|

SUS304 stainless steel, five holes, with five manual butterfly value, with water receiver pan

|

2

|