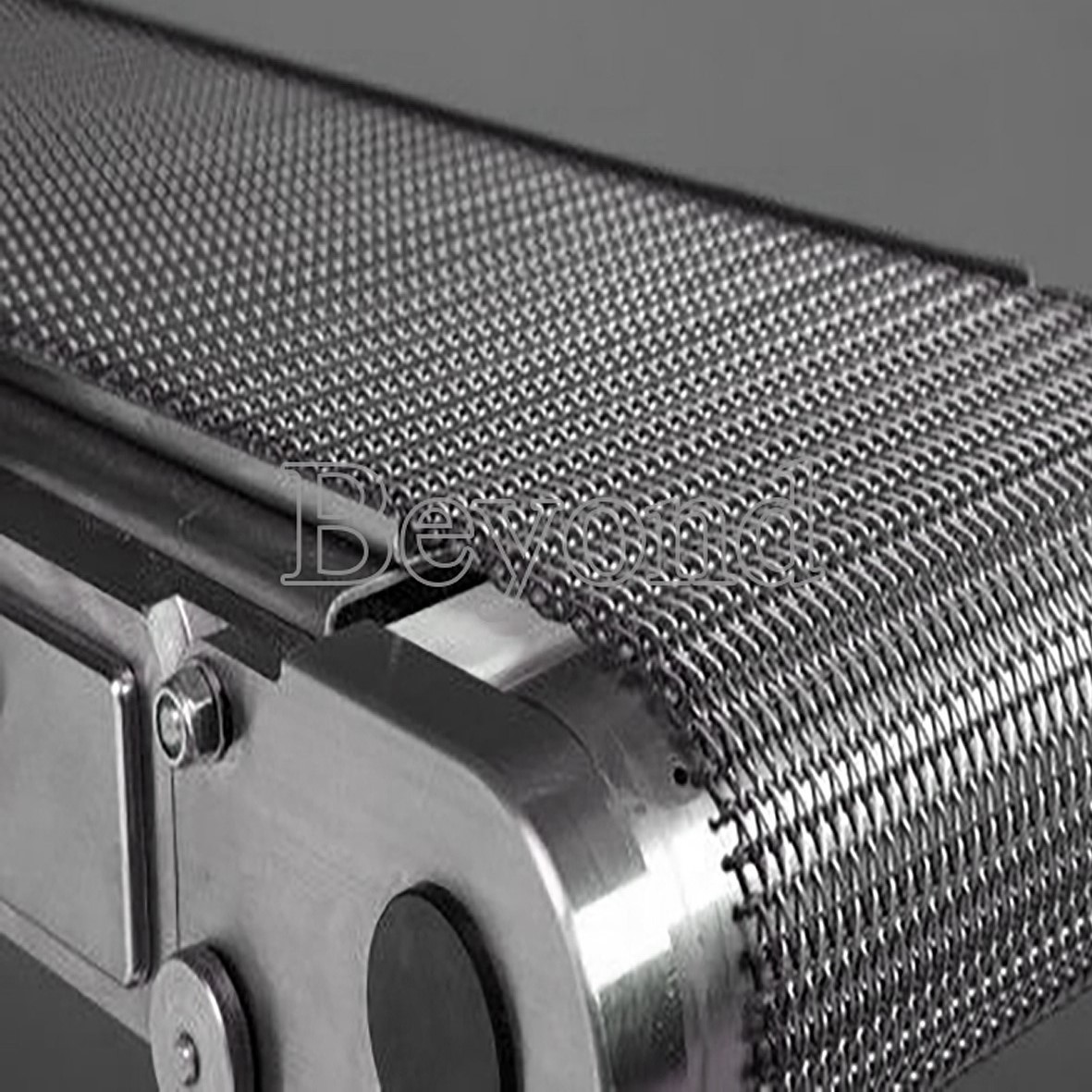

A mesh belt conveyor is a common material handling equipment that uses mesh belts as the conveying medium and transports materials from one location to another through plate chains or chains on the mesh belt. The mesh belt conveyor is mainly composed of conveyor belts, driving devices, return devices, rollers, and other components.

The following are the characteristics of the mesh belt conveyor:

Strong adaptability: The mesh belt conveyor has a wide range of adaptability and can transport various types of materials, including loose materials, block materials, and high-temperature materials. And different materials of mesh belts can be selected based on material characteristics, such as stainless steel mesh belts, polyester mesh belts, etc.

Smooth transportation: The conveying process of the mesh belt conveyor is stable and reliable, reducing the crushing and damage of materials, and is suitable for occasions with high material requirements.

Suitable for long-distance transportation: As the structure of the mesh belt conveyor can be customized according to actual needs, it can achieve long-distance transportation, and the conveyor line can be bent or tilted according to on-site conditions.

Easy to clean and maintain: The structure of the mesh belt conveyor is simple, without stuck screws and difficult to clean components, making it easy to clean. At the same time, maintenance is relatively convenient. Regular inspection of the tension of the mesh belt, cleaning of debris, and lubrication can effectively extend the service life of the equipment.

Can achieve automated production: The mesh belt conveyor can be combined with other equipment to operate, achieving a fully automated production process. It can be controlled according to production needs, such as adjustable speed, stable stop, etc.

Mesh belt conveyors are widely used in industries such as food processing, electronics, automotive manufacturing, pharmaceuticals, and chemical engineering, playing an important role in handling material loading and unloading, sorting, and assembly lines.

Wire mesh conveyors can be standard or custom made, for 24″to 84″wide loads up to 8,000 lbs and driven by fixed or variable speed drives, rated for food grade, or severe duty industrial grade. Some customers use wire mesh to allow hot objects to cool down in transit. Each metal belt has riveted galvanized steel mesh driven by steel sprockets on a common drive shaft. Wire mesh is also built with plastic belts for wash-down and light duty applications.

Type

Wire mesh belt

Material

Stainless Steel

Usage/Application

Fruit Washing, Grading Enrober belts / enrober wire belts

Cross Wire Diameter

1 mm, 1.2 mm, 1.5 mm, 1.6 mm, 1.8 mm, 2 mm, 2.3 mm, 2.35 mm

Pitch Roller Chain

4.8 mm to 12.7 mm

Grade

SS 304, SS 316

Custom Engineered

Wire Mesh Belt Conveyors are custom manufactured in a variety of shapes and sizes for your application requirements.

Belting offered in carbon steel, stainless steel or galvanized steel options.

Type of mesh belt determined by application, drive systems, safety equipment and controls.

Mesh Belt Conveyors, also known as wire mesh conveyors, are a specialized type of conveying system widely utilized in various industries due to their unique design and functionality. Here are some key technological:

7. Integration with Process Control Systems: Like plate conveyors, mesh belt conveyors can be seamlessly integrated into automated systems, allowing for precise control over speed, temperature, and other process variables.