Dairy Processing Line

1. Reception and Pre-treatment:• Milk reception: Raw milk is received from farms and undergoes initial testing for quality parameters (e.g., fat content, acidity, somatic cell count) before being pumped into storage tanks.• Standardization: Milk may be standardized by adjusting its fat and protein content to meet product specifications.• Preheating & Clarification: Milk is preheated to facilitate further processing and then passed through a clarifier or separator to remove any remaining impurities, such as fat globules, sediment, and bacteria.

2. Pasteurization / Sterilization:• Heat treatment: Milk is subjected to either pasteurization (high-temperature short-time, HTST) or ultra-high temperature (UHT) processing to destroy pathogenic microorganisms and extend shelf life.• Homogenization: To prevent cream separation, milk is homogenized by forcing it through narrow gaps at high pressure, breaking down fat globules into smaller, more uniform particles.

3. Further Processing:• Separation & Fractionation: For specialized dairy products like skim milk, cream, or whey, separation equipment is used to fractionate milk components based on their density.• Formulation & Mixing: Ingredients such as sweeteners, stabilizers, flavors, and vitamins may be added to the milk or milk fractions to create specific products like flavored milk, yogurt, or cheese mixtures.• Thickening & Coagulation: Processes like fermentation (for yogurt and cheese), acidification (for sour cream), or enzyme-based coagulation (for cheese) are used to thicken and solidify milk products.

4. Filling & Packaging:• Filling machines: Products are filled into containers (bottles, cartons, pouches, etc.) using automated filling equipment that ensures accurate volume control and seals the packaging to maintain product freshness.• Labeling & Coding: Packages are labeled with product information, expiration dates, and batch codes, and may undergo shrink wrapping or secondary packaging for transportation and retail display.

Beverage Processing Line

1. Raw Material Preparation:• Water treatment: Water, the primary ingredient for most beverages, undergoes filtration, reverse osmosis, deionization, and/or UV sterilization to ensure purity and desired mineral content.• Ingredient handling: Other ingredients such as fruits, juices, concentrates, sweeteners, acids, and flavorings are prepared, mixed, and stored as needed.

2. Blending & Mixing:• Batch mixing: Ingredients are combined in precise proportions according to recipes in mixing tanks, often with agitation to ensure homogeneity.• Continuous blending: For high-volume production, ingredients can be continuously metered and blended inline using automated dosing systems.

3. Pasteurization / Sterilization:• Heat treatment: Similar to dairy processing, beverages are pasteurized (HTST) or sterilized (UHT) to eliminate pathogens and extend shelf life.

4. Carbonation & Flavor Incorporation:• Carbonation: For carbonated beverages, CO2 is dissolved into the liquid under pressure.• Flavor addition: Flavorings, either natural or artificial, may be added during or after heat treatment, depending on their stability and compatibility with processing conditions.

5. Filling & Packaging:• Filling machines: Beverages are filled into appropriate containers (bottles, cans, PET bottles, etc.) using high-speed filling lines with precise fill-level control and efficient capping or sealing mechanisms.• Labeling & Coding: Similar to dairy products, packages are labeled and coded, and may also undergo shrink wrapping, case packing, or palletizing for distribution.

Both dairy and beverage processing lines typically include rigorous cleaning-in-place (CIP) systems to sanitize equipment between production runs, as well as quality control checkpoints throughout the process to monitor critical parameters (e.g., pH, Brix, color, turbidity) and ensure compliance with food safety regulations and product specifications.

Additionally, modern lines often integrate advanced technologies like computerized process control systems, data acquisition systems, and real-time monitoring tools for enhanced efficiency, traceability, and overall process management.

The dairy beverage processing line adopts multiple advanced technologies and equipment to ensure product quality, food safety, production efficiency, and product diversity. Here are some highlights of this type of processing line technology:

Homogenization technology: Homogenizers are crucial in the production of dairy beverages, as they refine the fat particles in milk under high pressure, making their distribution more uniform, thereby reducing fat floating and sedimentation, improving product taste and appearance. The homogenized dairy beverage appears whiter and has a delicate texture, enhanced stability, and helps to extend its shelf life.

• Aseptic cold filling technology: This is an advanced filling method used for fruit juices, dairy products, and other beverages, ensuring that products are filled under sterile conditions without the need for high-temperature heat treatment to achieve commercial aseptic status. Cold filling can maximize the retention of the nutritional and flavor components of beverages, reduce the loss of heat sensitive ingredients, and reduce energy consumption.

Ultrafiltration technology: Ultrafiltration technology is used in dairy processing for pre concentration, whey treatment, lactose refining, desalination, and separation and concentration of whey protein. For example, high protein content milk powder can be obtained through ultrafiltration of skimmed milk, enhancing the nutritional value of the product. This technology improves the utilization of raw materials, enriches product varieties, and helps develop high value-added dairy products.

• Concentration equipment: The multi effect evaporator used in dairy processing is an efficient and energy-saving concentration equipment, especially widely used in milk powder production. Compared to single effect and double effect evaporators, multi effect evaporators can more effectively utilize energy by gradually utilizing the heat released by steam condensation through multiple series connected evaporator units, greatly reducing energy consumption.

Plate heat exchanger: It is used for the cooling process of dairy products and has the characteristics of simple structure, high cooling efficiency, and good hygiene conditions. It avoids the possible pollution risk caused by the direct exposure of lotion to the air in the traditional surface cooler. When cold brine is used as the refrigerant, the cooling effect is more significant, which helps to quickly stabilize the dairy temperature and ensure the product quality.

• Cold processing technology: Dairy cold processing technology includes but is not limited to using efficient coolers (such as plate heat exchangers) to quickly cool raw milk, suppress microbial activity, extend the shelf life of raw milk, and provide high-quality raw materials for subsequent processing. Cold processing can also reduce the impact of heat treatment on the nutritional composition and taste of dairy products.

• Automation Control System: Modern dairy and beverage processing lines are usually equipped with advanced automation control systems, including process monitoring, data acquisition, fault warning, remote diagnosis and other functions, to achieve precise control of process parameters (such as temperature, pressure, flow rate, etc.), ensure product quality consistency, improve production efficiency, and reduce manual intervention and operational errors.

• Cleaning and Disinfection System: CIP (Cleaning In Place) online cleaning system and SIP (Sterilization In Place) in-situ disinfection system are standard equipment for dairy beverage processing lines, which can automatically clean and disinfect equipment pipelines, ensuring high hygiene standards in the production environment and complying with strict food safety regulations.

In summary, the highlight technologies of the dairy beverage processing line cover multiple links such as raw material processing, sterilization, concentration, filling, cooling, and automation control. Together, they promote the modernization process of the dairy processing industry, ensuring the safety, nutrition, and quality of products, and also enhancing the overall competitiveness of the industry.

The installation and debugging of a dairy beverage processing line is a complex and precise process, involving multiple links such as the assembly of mechanical equipment, connection of electrical systems, configuration of automation control systems, and trial operation testing of the entire production line.

The following is a general overview of the steps:

Design planning and infrastructure construction:

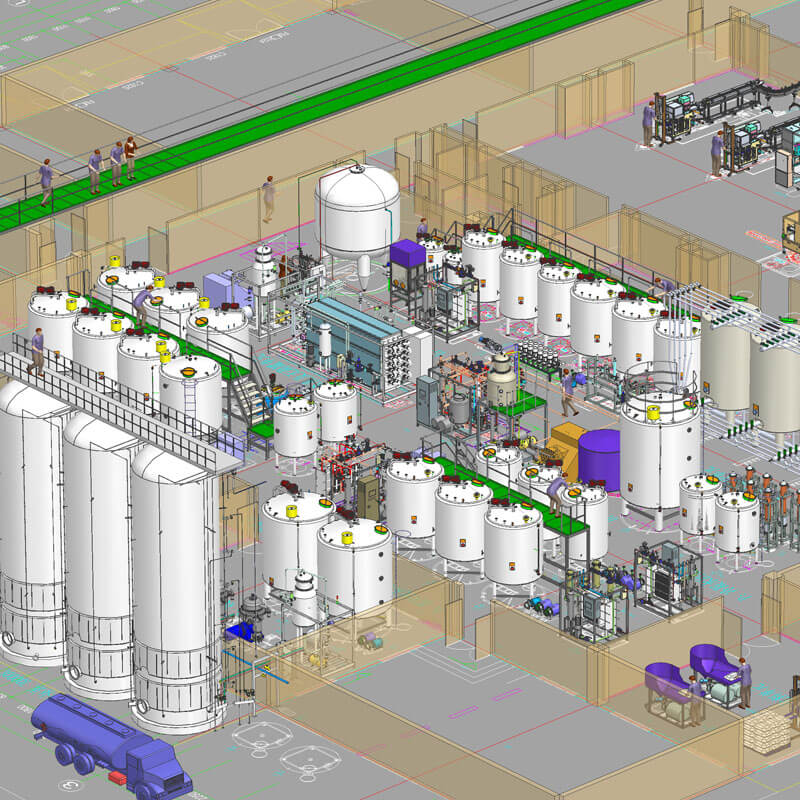

Based on the factory layout and technical requirements of the dairy beverage processing line, carry out detailed planning and design, including the spatial layout of the production line and the access points of public facilities (such as water and electricity, compressed air, refrigeration system, etc.).

Complete the infrastructure and supporting facilities construction required for the processing line.

Equipment installation: According to the design drawings and the installation manual provided by the manufacturer, position and install various parts of the processing line equipment, including raw material processing equipment, tanks, conveying systems, heating/cooling equipment, filtration and sterilization devices, filling and sealing machines, packaging equipment, etc.

The pipeline connections between equipment must comply with food hygiene standards, using appropriate connection materials and sealing methods to ensure the safety and reliability of material transmission.

• Electrical system wiring and connection: • Complete the laying of power supply lines to ensure stable and reliable power supply According to the electrical drawings, correctly connect the electrical components of each equipment, including motors, sensors, controllers, instruments, etc., and ensure proper grounding protection.

• Automation control system integration: • Configure and install PLC (Programmable Logic Controller) or other automation control systems, connect various sensors, actuators, and control panels Write and debug program logic to ensure that each link of the production line starts, runs, and stops according to the preset process sequence.

After completing the single machine debugging, carry out the linkage debugging of the entire production line, simulate the actual production process, and check the stability and smoothness of the collaborative work between various equipment.

• Verification of cleaning and disinfection system: • Conduct comprehensive installation and functional testing of the CIP/SIP system to ensure that all areas in contact with the product are effectively cleaned and disinfected.

Production testing and quality inspection: Use simulated materials or actual raw materials for trial production, observe and record various parameters of the entire production process, and adjust and optimize process parameters in a timely manner Strictly conduct quality testing on the produced products to ensure they comply with national food safety standards and internal control requirements of the enterprise.

Personnel training and development of operating procedures:

Provide systematic training to operators to ensure they are familiar with the operating methods and maintenance regulations of new equipment Develop detailed operating procedures and emergency plans to ensure the continuous and stable operation of the production line after it is officially put into operation.

• Acceptance and Delivery: After the above debugging and trial operation, it is confirmed that the dairy beverage processing line meets various performance indicators and technical requirements, and a professional team is organized to conduct project acceptance.

After passing the acceptance inspection, the processing line will be handed over to the customer and officially put into use. Throughout the installation and debugging process, strict adherence to relevant national safety regulations and industry standards should be ensured to ensure the smooth progress of the project and the efficient operation of the production line. At the same time, after installation and debugging, it is necessary to regularly maintain the equipment to maintain the good operation of the production line.

Shanghai Beyond Machinery Co., Ltd

Beyond Machinery specializes in the design and manufacturing of cream separator machine. Please contact us now, and our professional technical engineers will customize the equipment plan for dairy & beverage processing line and provide a quotation. Please contact us now to obtain the latest equipment plan and quotation.