In the modern beverage industry, the demand for functional, healthy, and flavorful products has elevated the importance of three core systems: the Lactic acid bacteria beverage production line, the Milk beverage processing line, and the Juice beverage production line. Each line is engineered around a quartet of cutting-edge attributes—intelligent formulation, energy-efficient processing, controlled hydration and browning, and ultra-clean fermentation. Below, the article dissects the equipment architecture behind these lines, highlighting how modular skids, smart sensors, and hygienic design converge to deliver premium beverages consistently.

1. Intelligent Formulation System

At the heart of every contemporary line sits a PLC-driven intelligent formulation island. Mass-flow meters, loss-in-weight feeders, and NIR spectrometers continuously stream data to a central SCADA node. For the Lactic acid bacteria beverage production line, this system calculates the exact ratio of starter culture, skim milk base, and fruit prep, compensating in real time for seasonal Brix deviations in raw juice. The Milk beverage processing line exploits the same architecture to standardize fat and protein within ±0.03 %, while the Juice beverage production line uses AI algorithms to blend cloudy and clear concentrates for optimal turbidity and vitamin C retention. Recipe change-over is executed in under four minutes, eliminating flavor cross-contamination and slashing downtime.

2. High-Efficiency, Energy-Saving Production Core

Energy reduction is achieved through a cascade of heat exchangers, variable-frequency drives, and regenerative braking on rotary fillers. A triple-section plate heat exchanger recovers up to 92 % of thermal energy during skim milk pre-heating in the Milk beverage processing line, while the Lactic acid bacteria beverage production line employs an aseptic vacuum cooler that cuts post-fermentation cooling time by 35 %. In the Juice beverage production line, a falling-film evaporator powered by mechanical vapor recompression reduces steam demand by 28 %. All motors above 7.5 kW are fitted with IE5 synchronous reluctance drives, trimming electrical consumption by an additional 7 % across the plant.

3. Hydration & Browning Control Skid

The hydration and browning unit is a proprietary skid combining a high-shear powder dissolver with an inline Maillard reactor. In the Lactic acid bacteria beverage production line, the dissolver pre-hydrates milk proteins at 55 °C within 120 seconds, preventing lump formation and protecting probiotics from osmotic shock. The reactor then exposes the mix to 95 °C for 90 seconds, producing golden-brown flavor precursors without over-cooking the culture. The Milk beverage processing line uses the same skid to create caramel notes in latte-style drinks, while the Juice beverage production line bypasses the heating section to retain fresh, bright color.

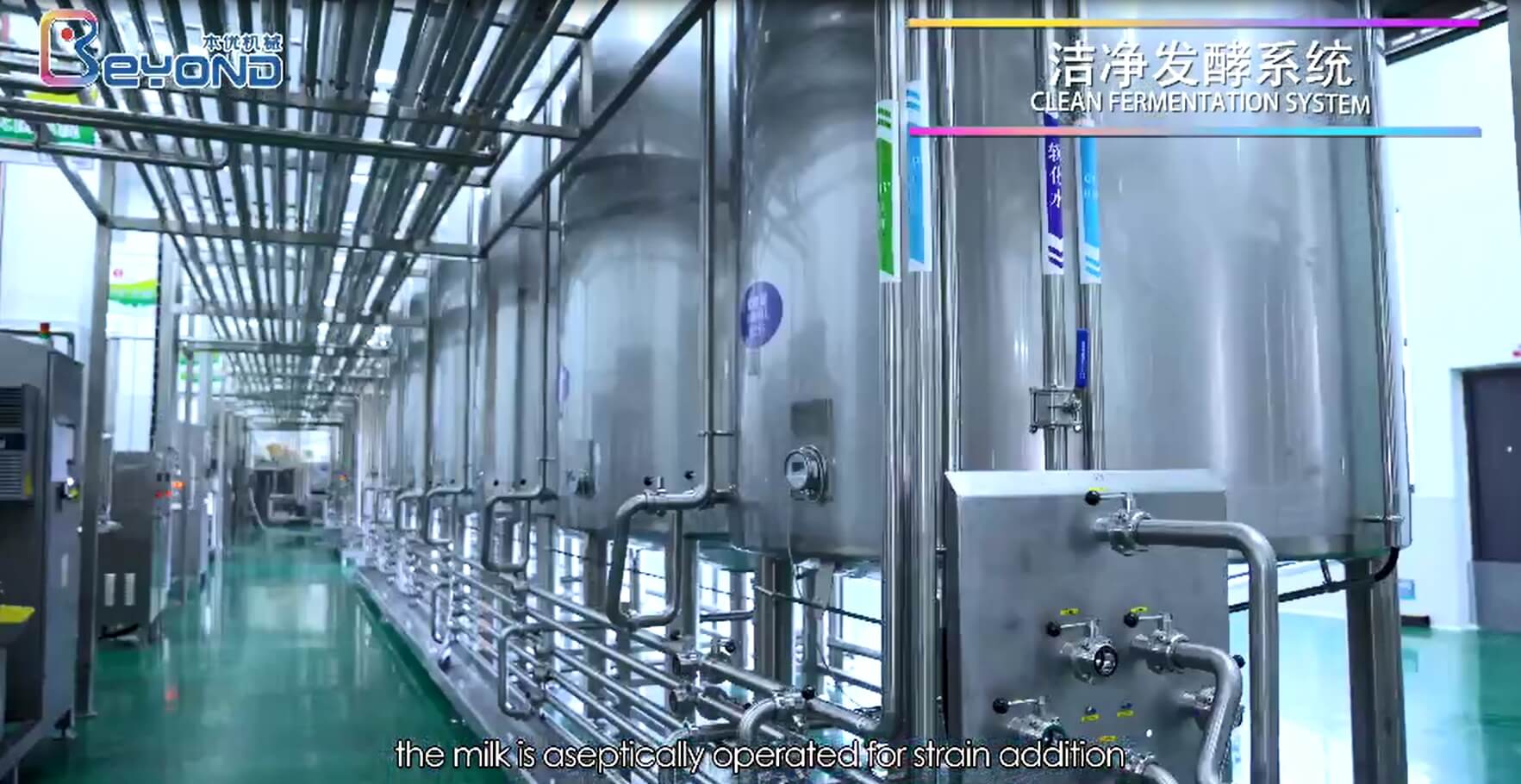

4. Ultra-Clean Fermentation Module

Fermentation is executed in a fully sealed, CIP-able tank battery rated SIP at 121 °C. Each 15 000-liter vessel in the Lactic acid bacteria beverage production line features a bottom-entering magnetic agitator and a dissolved-CO₂ probe that maintains anaerobiosis within 0.05 bar. The Milk beverage processing line leverages the same tanks for extended shelf-life yogurt drinks, while the Juice beverage production line repurposes them for controlled wild-fermentation of kombucha. A segregated CIP loop with peracetic acid and 85 °C water ensures biofilm elimination in under 25 minutes, achieving >6 log reduction in thermoduric spores.

5. Shared Utilities & Hygienic Integration

All three lines converge on an integrated utility backbone: softened water, instrument air, and 2 °C glycol are distributed through stainless-steel ring mains. Piping slopes of 3 % toward drain points eliminate dead legs, while orbital welding and 0.8 µm inter.

6. Traceability & Digital Twin

Every ingredient lot, temperature profile, and CIP cycle is logged to a blockchain ledger accessible through a cloud-based dashboard. A digital twin of the Milk beverage processing line predicts viscosity drift 30 minutes ahead, allowing operators to adjust shear rates pre-emptively. The Juice beverage production line twin forecasts enzymatic browning risk based on incoming fruit maturity, triggering an automatic increase in ascorbic acid dosing. Predictive maintenance algorithms analyze vibration data from fermentation agitators, scheduling bearing replacements during planned sanitation windows.

Conclusion